Author:

Charles Brown

Date Of Creation:

7 February 2021

Update Date:

1 July 2024

Content

If you've tried the boiler reset button, checked that fuel oil is present and your boiler still won't start, don't worry. Before calling the handyman or buying a new boiler, check the fuel source and make sure there is no air in the line. If there is no more fuel or it is running low, the boiler may not start even after you have added fuel. You probably just need to bleed a fuel line and then restart it.

To step

Part 1 of 2: Preparing to vent the boiler

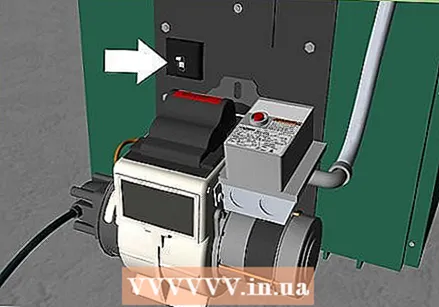

Turn off the boiler before you start working on the fuel pump. Depending on the model, you will probably need to press a switch somewhere close to the boiler or turn the boiler off at the main switch. You should also shut off the gas supply using the shut-off valve connected to the gas line.

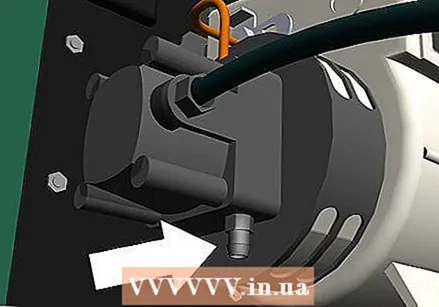

Turn off the boiler before you start working on the fuel pump. Depending on the model, you will probably need to press a switch somewhere close to the boiler or turn the boiler off at the main switch. You should also shut off the gas supply using the shut-off valve connected to the gas line.  Locate the bleeder screw on the fuel pump near the start of the fuel line. The screw is usually small and nipple-like in shape.

Locate the bleeder screw on the fuel pump near the start of the fuel line. The screw is usually small and nipple-like in shape.  Place a small bucket or pan under the vent screw. The bucket will catch any fuel that spouts out as you vent the boiler.

Place a small bucket or pan under the vent screw. The bucket will catch any fuel that spouts out as you vent the boiler. - If the screw is in a place where it is impossible to fit a bucket or small container, use a flexible tube that just fits over the vent screw. Place the tube over the bleed screw and point it to a place where you can place a container or bucket underneath.

Part 2 of 2: Vent the boiler

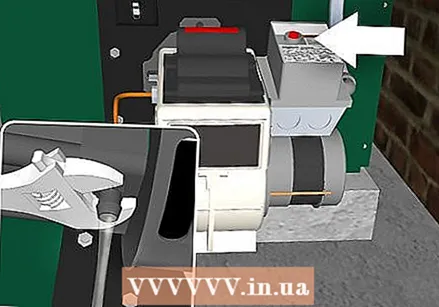

Use a small wrench or pliers to slightly loosen the bleeder screw. Make sure the screw stays attached to the pump and is just a bit loose so it doesn't fall off when you vent the boiler.

Use a small wrench or pliers to slightly loosen the bleeder screw. Make sure the screw stays attached to the pump and is just a bit loose so it doesn't fall off when you vent the boiler.  Press the boiler reset button to restart it. When the boiler starts to suck up fuel, air and fuel will spray out of the bleed screw.

Press the boiler reset button to restart it. When the boiler starts to suck up fuel, air and fuel will spray out of the bleed screw. - Keep your pliers and / or wrench on the screw to tighten it. This will also keep the screw in place if you have loosened it too much.

- When the boiler cycle ends before the air and fuel mixture stops sputtering, you must press the reset button again to continue the venting process until the boiler has pushed all the air out of the line.

- Some boilers may have a locking system that prevents you from resetting the boiler more than once or twice. When this happens, you can override this lock by pressing and holding the reset button until the boiler restarts.

Tighten the screw as soon as the air stops sputtering from the line and a steady stream of fuel flows out. Do not overtighten the screw. Replacing a damaged bleeder screw can be very costly.

Tighten the screw as soon as the air stops sputtering from the line and a steady stream of fuel flows out. Do not overtighten the screw. Replacing a damaged bleeder screw can be very costly.  Run the boiler. It should now work without any problems. If it does not restart next time, recheck the line for air by repeating the venting process. There may be air in the fuel line or clogged after the first run.

Run the boiler. It should now work without any problems. If it does not restart next time, recheck the line for air by repeating the venting process. There may be air in the fuel line or clogged after the first run.

Necessities

- Pliers or wrench

- Bucket

- Rubber gloves