Author:

Virginia Floyd

Date Of Creation:

9 August 2021

Update Date:

1 July 2024

Content

- Steps

- Method 1 of 2: Winding a watch with a plug and crown

- Method 2 of 2: Winding a watch with a connector and a chain

- Tips

- Warnings

- What do you need

Watches made in the old tradition require that they be wound from time to time in order to function. A watch cabinet is a clock on the floor, controlled by the falls of weights and the movement of a pendulum, and shaped like a tall cabinet. Follow the instructions to wind up any type of watch cabinet.

Steps

Method 1 of 2: Winding a watch with a plug and crown

1 Look for points to wind up your watch. If your watch case is wound with a crank or key, then it should have one to three small holes on the dial. Often, they are located near the numbers 3 (III), 9 (IX), in the center or somewhere in the lower half of the dial. If you do not see the holes or your watch case does not come with a crank or key, then proceed to the next step and read the instructions for winding a watch case with a connector and a chain.

1 Look for points to wind up your watch. If your watch case is wound with a crank or key, then it should have one to three small holes on the dial. Often, they are located near the numbers 3 (III), 9 (IX), in the center or somewhere in the lower half of the dial. If you do not see the holes or your watch case does not come with a crank or key, then proceed to the next step and read the instructions for winding a watch case with a connector and a chain.  2 Take out a crank or wrench of the correct size. Recently purchased watches of this type usually come with a winder or key, but if you have purchased a pre-owned watch or a watch case that has a new winding part, then you can find a suitable tool online or buy it from a watchmaker. Open the door that protects the dial and accurately measure the size of each hole using a ruler or tape measure with millimeter marks (mm), or better yet, a vernier caliper with a 0.25 mm pitch. Buy a handle or key with a shaft width that fits the holes on the dial to ensure easy and safe winding of the watch. You might prefer to buy three or four different sized instruments in case your measurements were slightly inaccurate.

2 Take out a crank or wrench of the correct size. Recently purchased watches of this type usually come with a winder or key, but if you have purchased a pre-owned watch or a watch case that has a new winding part, then you can find a suitable tool online or buy it from a watchmaker. Open the door that protects the dial and accurately measure the size of each hole using a ruler or tape measure with millimeter marks (mm), or better yet, a vernier caliper with a 0.25 mm pitch. Buy a handle or key with a shaft width that fits the holes on the dial to ensure easy and safe winding of the watch. You might prefer to buy three or four different sized instruments in case your measurements were slightly inaccurate. - Note:When purchasing a crown, make sure that the shaft is long enough so that the handle does not touch the hands of the watch, and you will not damage the watch by turning it 360º.

- Some manufacturers sell keys in numbered scales rather than shaft widths. However, there is no single system of scales for all manufacturers, therefore, it is recommended to be guided by measurements in millimeters.

3 Use the crank or key to wind the first weight. Carefully push a handle or wrench into one of the winding holes.The key should go through tightly, but without much effort. Gently hold the dial with one hand and gently turn the knob or key with the other. Try to turn in both directions, and see which one makes the plant easier to move; in each watch model the winding is individual - clockwise or counterclockwise. As you turn the key or handle, the weight below the rest should begin to rise up. Stop turning before the weight rises to the wooden side or the key no longer turns.

3 Use the crank or key to wind the first weight. Carefully push a handle or wrench into one of the winding holes.The key should go through tightly, but without much effort. Gently hold the dial with one hand and gently turn the knob or key with the other. Try to turn in both directions, and see which one makes the plant easier to move; in each watch model the winding is individual - clockwise or counterclockwise. As you turn the key or handle, the weight below the rest should begin to rise up. Stop turning before the weight rises to the wooden side or the key no longer turns. - If you cannot easily turn the key or you cannot see the weight moving, then you should check, perhaps one of the weights is already at the top. If one or several bells in the clock are disabled, then the weight responsible for this bell and its timely ringing will not go down and it does not need to be started.

- The weights are usually located above the pendulum. You may or may not need to open the bottom of the watchcase to see them.

4 Repeat the process with the other plant holes. If your watch has more than one weight, then there should be more than one hole on the dial. Move the winding handle or wrench to the next hole, and turn until each weight moves up to its highest point, practically touching the wooden plank above it.

4 Repeat the process with the other plant holes. If your watch has more than one weight, then there should be more than one hole on the dial. Move the winding handle or wrench to the next hole, and turn until each weight moves up to its highest point, practically touching the wooden plank above it.  5 Make neat adjustments if necessary. Now is the time to check if the clock is still showing the correct time. If not, then you can manually turn only the minute hand in the hour direction until the watch shows the correct time. Always stop at 12 (XII) to allow the clock to advance to the next hour. Do this for other holes as well if the clock strikes at the wrong time (usually, the clock should strike at 3, 6, and 9 o'clock).

5 Make neat adjustments if necessary. Now is the time to check if the clock is still showing the correct time. If not, then you can manually turn only the minute hand in the hour direction until the watch shows the correct time. Always stop at 12 (XII) to allow the clock to advance to the next hour. Do this for other holes as well if the clock strikes at the wrong time (usually, the clock should strike at 3, 6, and 9 o'clock). - There are watch models in which you can turn the minute hand counterclockwise, but don't risk it if you're not sure. If the minute hand does not give in when you turn it clockwise, but easily turns against it, then you may be the owner of a non-standard model, the minute hand of which needs to be turned counterclockwise.

- If your clock is running too fast or too slow, look for a knob or nut on the bottom moving part of the pendulum. Tighten it more (to the right) to slow down the watch, or loosen it (to the left) to speed it up.

6 Wind your watch weekly or as needed. Almost all watch cases are designed to last seven to eight days without a factory, so winding them up on the same day every week will ensure they never stop. If your watch has stopped before it is regularly wound, then you need to wind it up more often.

6 Wind your watch weekly or as needed. Almost all watch cases are designed to last seven to eight days without a factory, so winding them up on the same day every week will ensure they never stop. If your watch has stopped before it is regularly wound, then you need to wind it up more often.

Method 2 of 2: Winding a watch with a connector and a chain

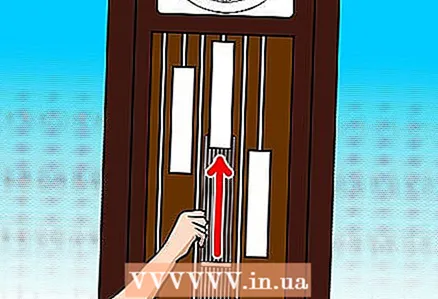

1 Find the chains hanging next to the weights. Open the door that protects the inside of the cabinet under the dial, where the weights are hanging. Most watches have one, two or three weights, but there are also non-typical watch cases. If you find chains hanging next to each of the weights, then most likely your watch cabinet is of the connector-chain type.

1 Find the chains hanging next to the weights. Open the door that protects the inside of the cabinet under the dial, where the weights are hanging. Most watches have one, two or three weights, but there are also non-typical watch cases. If you find chains hanging next to each of the weights, then most likely your watch cabinet is of the connector-chain type. - If you do not find any chain or holes on the watch dial, then you should ask someone to help you, or consult a professional watchmaker or consultant in a watch repair shop.

2 Pull one of the chains carefully. Grasp the chain next to the weight that is not at the top of the cabinet. Pull down the chain slowly and you will see the weight lift up. Continue until the weight is almost up to the wooden plank, or the chain continues to give way easily.

2 Pull one of the chains carefully. Grasp the chain next to the weight that is not at the top of the cabinet. Pull down the chain slowly and you will see the weight lift up. Continue until the weight is almost up to the wooden plank, or the chain continues to give way easily. - Pull down the chain that is near with a weight, but never the one on which the weight hangs.

- It doesn't matter which of the weights you start first.

3 Repeat the manipulations with the following weights. Each weight has its own chain. Gently pull down each chain in turn until the weight it is responsible for reaches the top bar above it. Your watch is fully wound with each of the weights as high as possible, practically touching the top wooden bar.

3 Repeat the manipulations with the following weights. Each weight has its own chain. Gently pull down each chain in turn until the weight it is responsible for reaches the top bar above it. Your watch is fully wound with each of the weights as high as possible, practically touching the top wooden bar. - Usually, it is the central weight that is responsible for keeping the clock in the correct course of time. If there are other weights in your watch cabinet, they are often responsible for the hour hand or for the striking of the clock.

4 Make adjustments if necessary. Turn manually minute hand, not hour, if you need to set the correct time on the watch. Turn the minute hand clockwise if you do not feel the counter-movement of the hand as you go in that direction. Hold the dial with your free hand. Be careful to prevent the hand from bending or breaking, and stop from time to time and wait for the watch to adjust to the new time before continuing to turn the hand.

4 Make adjustments if necessary. Turn manually minute hand, not hour, if you need to set the correct time on the watch. Turn the minute hand clockwise if you do not feel the counter-movement of the hand as you go in that direction. Hold the dial with your free hand. Be careful to prevent the hand from bending or breaking, and stop from time to time and wait for the watch to adjust to the new time before continuing to turn the hand. - You can tighten the nut at the bottom of the pendulum harder (to the right) to slow down the clock, or loosen it (to the left) to speed it up. Adapt to do this every week or two.

Tips

- If you do not want your clock to strike every three hours or every hour, then do not wind the two weights that are responsible for this aspect. You can also look for a lever on the dial or on the side of the watchcase that will allow you to turn off the striking of the clock at night or completely.

- If the dial of your watch has a moving disc responsible for the lunar period, you can correct the display of the moon phase by gently pressing the dial and turning it clockwise. This also applies to other small moving discs on your watch face.

Warnings

- If the crank or key does not turn without resistance and the chain does not pull down easily, then do not continue. Contact a professional.

- Do not use force when inserting the crank or key into the opening on the dial.

What do you need

- Crown or clock key