Author:

Helen Garcia

Date Of Creation:

15 April 2021

Update Date:

1 July 2024

Content

- Steps

- Method 1 of 2: Fill a syringe with a reservoir.

- Method 2 of 2: Filling the cartridge syringe

- Warnings

- What do you need

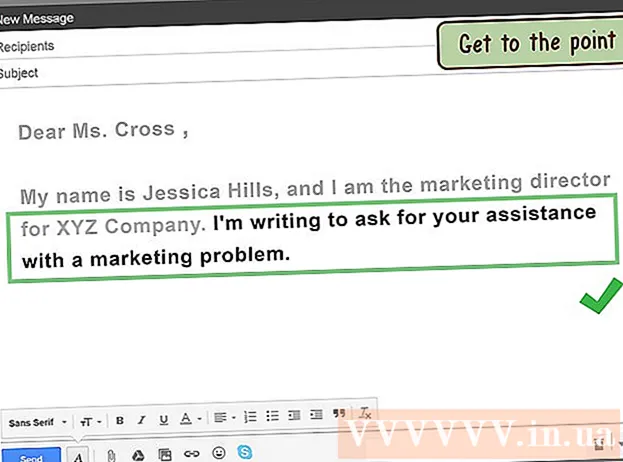

Grease guns are used to fill moving mechanical parts with viscous grease, most often used in mechanical and auto repair shops. Well-lubricated moving metal parts increase machine life and reduce wear. The lubricant used to fill the syringe is sold at most hardware and auto parts stores. Filling a syringe is a little messy but uncomplicated, whether with a cartridge or with a regular reservoir.

Steps

Method 1 of 2: Fill a syringe with a reservoir.

1 Separate the head of the syringe from the body. If you have a large container of grease, filling the syringe will be more efficient. First, unscrew the head from the syringe barrel. The head is the part with the handle and the applicator tube. Unscrew them from the syringe and separate from the body.

1 Separate the head of the syringe from the body. If you have a large container of grease, filling the syringe will be more efficient. First, unscrew the head from the syringe barrel. The head is the part with the handle and the applicator tube. Unscrew them from the syringe and separate from the body. - Make sure the handle on the back of the syringe, which is the stem handle, is fully pushed into the inside of the syringe, otherwise you risk accidentally sucking grease into the syringe during filling.

2 Insert the open end of the housing into a container of grease. While holding the syringe in a container of grease, slowly pull the stem towards you to fill the body with grease.

2 Insert the open end of the housing into a container of grease. While holding the syringe in a container of grease, slowly pull the stem towards you to fill the body with grease. - Grease cans are sold in auto and hardware stores, and are commonly used in auto repair shops instead of cartridge syringes. If you are a mechanic, then this is a great option for you.

3 Remove the syringe from the grease container. When the piston rod is fully extended upward, remove the open end of the housing from the grease. Rotate it a few times to remove any adhering grease. Using a rag, wipe off excess grease from the end of the housing.

3 Remove the syringe from the grease container. When the piston rod is fully extended upward, remove the open end of the housing from the grease. Rotate it a few times to remove any adhering grease. Using a rag, wipe off excess grease from the end of the housing.  4 Attach the head of the syringe to the body. Different syringes are designed differently. On some, the head is screwed on, while on others the nozzle is screwed on. Either way, twist them until they are completely seated.

4 Attach the head of the syringe to the body. Different syringes are designed differently. On some, the head is screwed on, while on others the nozzle is screwed on. Either way, twist them until they are completely seated.  5 Check the lubricant supply. Push down on the stem handle and squeeze the handle or trigger of the syringe until grease appears at the end of the applicator tube. Wipe off excess grease from the end of the tube and syringe body. Clean the syringe with a rag and prepare it for use.

5 Check the lubricant supply. Push down on the stem handle and squeeze the handle or trigger of the syringe until grease appears at the end of the applicator tube. Wipe off excess grease from the end of the tube and syringe body. Clean the syringe with a rag and prepare it for use.

Method 2 of 2: Filling the cartridge syringe

1 Unscrew the syringe cap. Cartridge syringes have two main parts: a grease cartridge, about the same size as the syringe, and a cap with a nozzle through which grease flows. To remove the cartridge, usually, it is enough to twist the cap, under which the cartridge is located, clockwise, at the same time, turn the syringe itself counterclockwise. It may be difficult to unscrew, so you have to put in some effort.

1 Unscrew the syringe cap. Cartridge syringes have two main parts: a grease cartridge, about the same size as the syringe, and a cap with a nozzle through which grease flows. To remove the cartridge, usually, it is enough to twist the cap, under which the cartridge is located, clockwise, at the same time, turn the syringe itself counterclockwise. It may be difficult to unscrew, so you have to put in some effort.  2 Pull out the metal rod. In the center of the body, where the cartridge is held, opposite the cap with the nozzle, there is a piston rod, which presses on the cartridge and squeezes out the grease. Continue to pull the stem out until it comes out of the body.

2 Pull out the metal rod. In the center of the body, where the cartridge is held, opposite the cap with the nozzle, there is a piston rod, which presses on the cartridge and squeezes out the grease. Continue to pull the stem out until it comes out of the body. - On some grease guns, pulling out the stem will automatically eject the cartridge. Depending on how much grease is inside, it can come out completely or half. Before you take out the cartridge, you need to secure the stem.

3 Lock the stem and remove the cartridge. With most grease guns, you need to move the stem slightly to the side, into a slot in the body so that it cannot move forward. Some grease guns have a latch when the stem is fully retracted, and there is a release plate at the end of the body that allows the stem to move again.

3 Lock the stem and remove the cartridge. With most grease guns, you need to move the stem slightly to the side, into a slot in the body so that it cannot move forward. Some grease guns have a latch when the stem is fully retracted, and there is a release plate at the end of the body that allows the stem to move again. - When the stem is secured, you can pull out the empty cartridge and discard it.

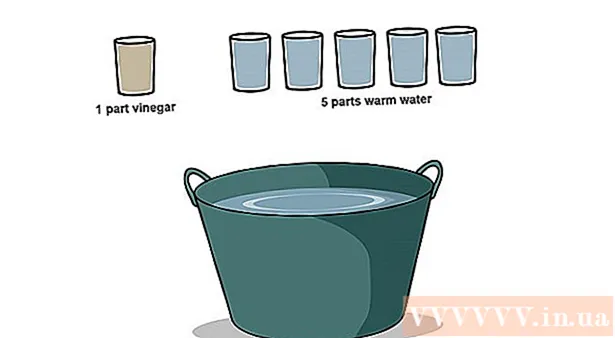

4 Prepare a new grease cartridge for installation. The cartridges are usually sold in auto and hardware stores. The standard cartridge sizes are 414 ml and 473 ml. It is best to wipe the syringe clean before installing a new cartridge. Wipe the end of the case with a piece of cloth or rag.This will remove any excess grease that has been squeezed out during the removal of the used cartridge.

4 Prepare a new grease cartridge for installation. The cartridges are usually sold in auto and hardware stores. The standard cartridge sizes are 414 ml and 473 ml. It is best to wipe the syringe clean before installing a new cartridge. Wipe the end of the case with a piece of cloth or rag.This will remove any excess grease that has been squeezed out during the removal of the used cartridge. - Before installing a new cartridge, remove the cap from the cartridge so that grease can flow out without obstruction.

- It is recommended to store the grease cartridges upside down so that the grease will be in the right place at the nozzle. If the cartridge was not stored upside down, then you need to shake it several times towards the cap so that the lubricant moves in the direction you need before installing the cartridge.

5 Insert the cartridge into the syringe body. Insert the cartridge first with the plastic cap on it. Insert the cartridge completely into the syringe so that the end of the seal cartridge aligns with the end of the syringe barrel. Remove the metal seal from the end of the cartridge. Throw away the metal seal.

5 Insert the cartridge into the syringe body. Insert the cartridge first with the plastic cap on it. Insert the cartridge completely into the syringe so that the end of the seal cartridge aligns with the end of the syringe barrel. Remove the metal seal from the end of the cartridge. Throw away the metal seal.  6 Screw the cap back onto the syringe body. Tighten two full turns, do not tighten too much. Release the piston rod from the locked position and push it into the body while pressing the handle on the syringe nozzle. This procedure will expel air from the syringe and begin to work normally. Stop pushing down on the handle when grease emerges from the nozzle of the syringe.

6 Screw the cap back onto the syringe body. Tighten two full turns, do not tighten too much. Release the piston rod from the locked position and push it into the body while pressing the handle on the syringe nozzle. This procedure will expel air from the syringe and begin to work normally. Stop pushing down on the handle when grease emerges from the nozzle of the syringe. - Screw the cap and body of the syringe back on at the same time. Push down on the piston rod to check that it is fully engaged with the new cartridge. Press down on the handle and check that the grease comes out.

Warnings

- If your syringe has a latch on the stem in a retracted position, do not press down on the release plate until the head and body of the syringe are connected. The stem has a compressed spring and it will quickly pop forward.

- After removing the metal seal on the replaced cartridge, the end of the cartridge and the removed seal will have sharp edges.

What do you need

- Grease gun

- Grease container

- Replacement grease cartridge

- Cleaning cloths