Author:

Mark Sanchez

Date Of Creation:

6 January 2021

Update Date:

1 July 2024

Content

For some, building and flying your own jet is an amazing experience. And in most countries it is perfectly legal to build your own aircraft. This is a beginner's guide for those who would like to tackle this exciting business. The results will be extremely beneficial to you and your family.

Steps

1 Make sure building your own aircraft is legal in your country - in the United States, building your own aircraft, even before you have a pilot's license, is completely legal.

1 Make sure building your own aircraft is legal in your country - in the United States, building your own aircraft, even before you have a pilot's license, is completely legal. 2 It is recommended to obtain a pilot's license first. You have to be clear about what you want to build, so you will need to fly different types of aircraft in advance. While studying the specifications, you will learn a lot, but only flying experience will help you understand the difference in performance, especially how the type of aircraft you want will suit your body type.

2 It is recommended to obtain a pilot's license first. You have to be clear about what you want to build, so you will need to fly different types of aircraft in advance. While studying the specifications, you will learn a lot, but only flying experience will help you understand the difference in performance, especially how the type of aircraft you want will suit your body type.  3 Decide if you want to make an airplane that has already been built or create your own. If you want it to fly fast enough, you need to use an existing design.

3 Decide if you want to make an airplane that has already been built or create your own. If you want it to fly fast enough, you need to use an existing design.  4 Decide if you want to build it using ready-made kits or according to plan and drawings. A well-assembled kit will speed up the process of creating an airplane, while using only a plan can sometimes get in the way.

4 Decide if you want to build it using ready-made kits or according to plan and drawings. A well-assembled kit will speed up the process of creating an airplane, while using only a plan can sometimes get in the way.  5 Decide what you want to build. There are three main types of aircraft construction: fabric, aluminum, and composite.

5 Decide what you want to build. There are three main types of aircraft construction: fabric, aluminum, and composite. - The fabric may not require much maintenance, but it creates a slower flight speed, is the lightest construction, and for some it may not be as difficult to build.

- Aluminum is more difficult, but does not require some maintenance and can make the plane very fast.

- Composite is the most difficult option to build because it requires sanding for finishing, but usually the fastest planes are obtained.

6 Look at the different designs and identify the goals you want: minimum consumption, good performance, practicality, etc. Please note: simple and practical projects, which are usually the most common and may be the best choice for a successful construction.

6 Look at the different designs and identify the goals you want: minimum consumption, good performance, practicality, etc. Please note: simple and practical projects, which are usually the most common and may be the best choice for a successful construction.  7 Take part in activities such as the EAA's annual summer Oshkosh Fly-In or Sun n 'Fun. There you can find the most renowned manufacturers of aircraft assembly kits. Spending most of your time talking to aircraft owners about their experience in building and flying will benefit you more than talking to manufacturers.

7 Take part in activities such as the EAA's annual summer Oshkosh Fly-In or Sun n 'Fun. There you can find the most renowned manufacturers of aircraft assembly kits. Spending most of your time talking to aircraft owners about their experience in building and flying will benefit you more than talking to manufacturers.  8 Call your aviation insurance agent and find out if you can get insurance based on your flight experience and what you think it will be like after the completion of your project. Some planes are not worth insuring because of their actual value, but you need to purchase liability insurance anyway. The amount of insurance that you are offered to pay shows how reliable your plane is.

8 Call your aviation insurance agent and find out if you can get insurance based on your flight experience and what you think it will be like after the completion of your project. Some planes are not worth insuring because of their actual value, but you need to purchase liability insurance anyway. The amount of insurance that you are offered to pay shows how reliable your plane is.  9 Fly on the plane that you want to build in order to understand if you like it more than others. Several manufacturers offer demonstration flights. Join your local experimental aviation association where you can network with those who already own the aircraft you want to build.

9 Fly on the plane that you want to build in order to understand if you like it more than others. Several manufacturers offer demonstration flights. Join your local experimental aviation association where you can network with those who already own the aircraft you want to build.  10 Find someone who is currently building what you plan to build. It doesn't have to be the exact same aircraft, ideally a similar design, or even best a generic manufacturer, which will give you the opportunity to learn construction techniques and kit quality. Don't be intrusive, as successful airplane builders are almost always time constrained and won't want to talk to you if you waste their time. When you decide to build your own plane, you will be able to avoid all the mistakes that many builders make, since you will know from the very beginning what you are doing.

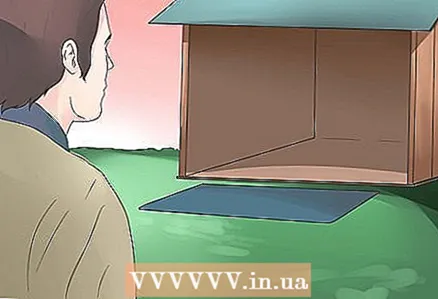

10 Find someone who is currently building what you plan to build. It doesn't have to be the exact same aircraft, ideally a similar design, or even best a generic manufacturer, which will give you the opportunity to learn construction techniques and kit quality. Don't be intrusive, as successful airplane builders are almost always time constrained and won't want to talk to you if you waste their time. When you decide to build your own plane, you will be able to avoid all the mistakes that many builders make, since you will know from the very beginning what you are doing.  11 Find a site to build your aircraft once you've decided on a specific design. A nearby garage or a large workshop in your home are the best options. Make sure you can keep the temperature above 10 degrees Celsius; you will not be able to work well with your hands in temperatures below 10 degrees Celsius.

11 Find a site to build your aircraft once you've decided on a specific design. A nearby garage or a large workshop in your home are the best options. Make sure you can keep the temperature above 10 degrees Celsius; you will not be able to work well with your hands in temperatures below 10 degrees Celsius.  12 Find the tools you need. Now that you have the perfect workplace, take the time to acquire all the tools you need. You can usually find them from people in the local experimental aviation association who have recently finished building their aircraft. If not, aircraft builders can point you in the right direction.

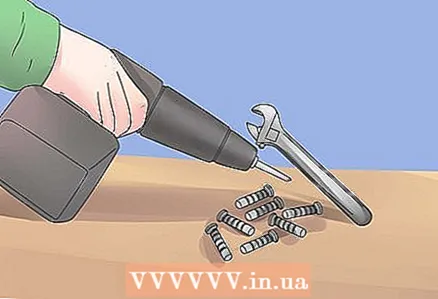

12 Find the tools you need. Now that you have the perfect workplace, take the time to acquire all the tools you need. You can usually find them from people in the local experimental aviation association who have recently finished building their aircraft. If not, aircraft builders can point you in the right direction.  13 Prepare your plans, blueprints and start building. The construction of an aircraft using kits from the manufacturer begins with a tail of "feathers" or formally a "tail". The assembly of the tail assembly will become a microcosm of the project without determining the full cost of the entire project. This is a lifeline for those who did not receive help from another developer before starting construction. You can look at various classified ads, and purchase the plumage essentials you want to make from builders who have a lot of experience in the matter.

13 Prepare your plans, blueprints and start building. The construction of an aircraft using kits from the manufacturer begins with a tail of "feathers" or formally a "tail". The assembly of the tail assembly will become a microcosm of the project without determining the full cost of the entire project. This is a lifeline for those who did not receive help from another developer before starting construction. You can look at various classified ads, and purchase the plumage essentials you want to make from builders who have a lot of experience in the matter.  14 Follow the instructions carefully. Do not deviate from the plan, only if you already have some building experience. Deviation costs time, money, and sometimes life. Generally, it is best to start with the tail (shown in step 13), but always follow the plan.

14 Follow the instructions carefully. Do not deviate from the plan, only if you already have some building experience. Deviation costs time, money, and sometimes life. Generally, it is best to start with the tail (shown in step 13), but always follow the plan.  15 Ask the Experimental Aviation Association's technical advisor to look at the plane and rate your work. It will also help save you money on insurance.

15 Ask the Experimental Aviation Association's technical advisor to look at the plane and rate your work. It will also help save you money on insurance.  16 Pay attention to how long others have been building your project to monitor their own progress. Some questions take time, which can take you away from your schedule. For example, insurance, engines, propellers and hangars. Find out the deadlines for each of them in advance and try to prepare them for the moment when you need it. 3 to 6 months of the possible duration of the flight on your plane, it must be registered.

16 Pay attention to how long others have been building your project to monitor their own progress. Some questions take time, which can take you away from your schedule. For example, insurance, engines, propellers and hangars. Find out the deadlines for each of them in advance and try to prepare them for the moment when you need it. 3 to 6 months of the possible duration of the flight on your plane, it must be registered.  17 Keep the plane at your home for as long as possible. It is much better to get the job done in 30 minutes while lunch is being prepared, when you only need 3 seconds to walk to your workshop; and besides, hangars cost a lot of money. It all depends on your workplace, but try to do as much as possible at home: install the engine and propellers; wiring, and maybe even painting. However, some people choose not to paint until the first test flight in order to reduce costs and be able to repair cracks if any have appeared in the composite structure.

17 Keep the plane at your home for as long as possible. It is much better to get the job done in 30 minutes while lunch is being prepared, when you only need 3 seconds to walk to your workshop; and besides, hangars cost a lot of money. It all depends on your workplace, but try to do as much as possible at home: install the engine and propellers; wiring, and maybe even painting. However, some people choose not to paint until the first test flight in order to reduce costs and be able to repair cracks if any have appeared in the composite structure.  18 Take the plane to the airport and do the final assembly.

18 Take the plane to the airport and do the final assembly. 19 Make sure you have enough fuel to support the propulsion system.

19 Make sure you have enough fuel to support the propulsion system. 20 Complete the required registration process.

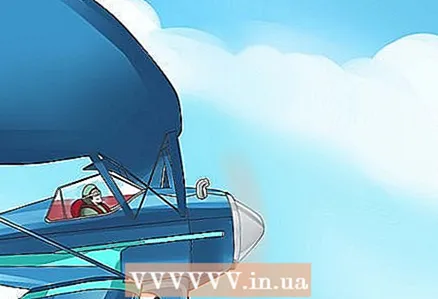

20 Complete the required registration process. 21 Go and fly, preferably a similar type of aircraft. It is possible that having plunged into construction, you completely abandoned flying. And this is bad. You need to fly. This is not the time to rush. Practice unusual airplane positions in the air and engine operation. Some stereotypes: some construction pilots are often distracted in flight by all kinds of gadgets they have installed and forget to directly control the plane and try different positions. Others are not very good at landing a plane without an engine.

21 Go and fly, preferably a similar type of aircraft. It is possible that having plunged into construction, you completely abandoned flying. And this is bad. You need to fly. This is not the time to rush. Practice unusual airplane positions in the air and engine operation. Some stereotypes: some construction pilots are often distracted in flight by all kinds of gadgets they have installed and forget to directly control the plane and try different positions. Others are not very good at landing a plane without an engine.  22 Ask a flight advisor from the Experimental Aviation Association to help you plan your first flight and probationary period.

22 Ask a flight advisor from the Experimental Aviation Association to help you plan your first flight and probationary period. 23 Get insurance.

23 Get insurance.

Tips

- Designing an airplane is not easy, consult with professionals or other experienced hobbyists.

- Consider joining EAA.org.

- Don't let difficulties deter you from building the plane of your dreams, but understand that building and flying the plane for the first time is difficult. Each step is a new challenge, because it has never been done by you yet.

- You can find a detailed log of RVProject.com builders here.

Warnings

- Airplanes can be deadly and therefore require pilot training and licensing for authorized flights. Check the requirements of your aviation service. In the United States, you can legally fly an ultralight aircraft without a license under the FAR, 103