Author:

Clyde Lopez

Date Of Creation:

17 June 2021

Update Date:

1 July 2024

Content

If the sewing machine is well debugged, then all its parts work in sync with each other. Debugging is important to get a quality stitch on the fabric. Correct setting of the correct needle is a critical component of sewing machine setup. Although the debugging process is the same for most sewing machines, the methods for removing, adjusting, and installing parts are different for machines. Refer to the manual for your sewing machine as you progress through the debugging procedure. Follow the tips below to adjust the sewing machine.

Steps

1 Take out the bobbin case. Remove the bobbin case from the slot. Do this according to your sewing machine instructions.

1 Take out the bobbin case. Remove the bobbin case from the slot. Do this according to your sewing machine instructions.  2 Check the condition of the needle. It should not be bent. If the game is bent, dull, or damaged, the machine may skip stitches.

2 Check the condition of the needle. It should not be bent. If the game is bent, dull, or damaged, the machine may skip stitches.  3 Install the needle. Follow the instructions for your sewing machine.

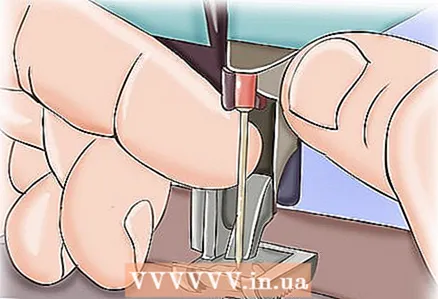

3 Install the needle. Follow the instructions for your sewing machine. - The needle must be inserted all the way.

- Tighten the needle locking screw. A dangling needle will have a negative effect on stitch quality.

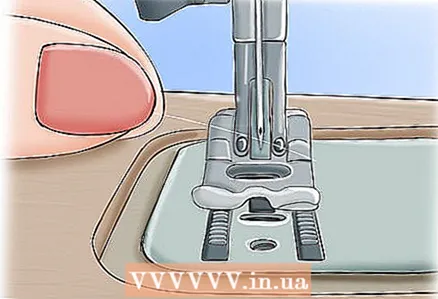

4 Check the position of the needle.

4 Check the position of the needle.- Look into the bobbin case slot.

- Roll the handwheel towards you. Rotate the wheel slowly so that you can see the movement of the needle in the socket.

- Look at the hook on the hook. The eye of the needle at the lowest point should drop 2.4 mm below the highest point of the hook.

- Pull the needle bar down if the eye of the needle is above the hook.Raise the needle bar if the eye of the needle is more than 2.4 mm below the hook. Refer to the sewing machine manual for how to adjust the position of the needle bar.

5 Check that the thread passes through all the guides properly.

5 Check that the thread passes through all the guides properly.- Thread the sewing machine. Follow the instructions for refueling the sewing machine.

- Turn the flywheel.

- Make sure that the thread passes through all the guides normally and does not get caught.

6 Check the thread tension regulator for accumulated lint.

6 Check the thread tension regulator for accumulated lint.- Remove the threads from the sewing machine.

- Check that there is no lint in the thread tension regulator.

- Dip a clean, narrow strip of cotton cloth in the cleaning solvent.

- Slide it back and forth through the tension adjuster clamping washers. Any fluff trapped there should be removed and left on the fabric.

- Remove the fabric from the tension adjuster.

- Refuel the car. Follow the instructions for refueling the sewing machine.

What do you need

- Sewing machine

- Sewing machine manual

- Screwdriver

- Threads

- A piece of cotton fabric

- Cleaning solvent