Author:

Monica Porter

Date Of Creation:

14 March 2021

Update Date:

1 July 2024

Content

- If you're lucky, the reverse drill can feed into the bolt and take the bolt off a bit yourself, you will use the forceps to remove it completely.

- Remember to use a drill for the correct size. The drills in the toolkit have a guide board so you know what size to use based on the size of the bolt to be removed. Using a drill that is too large can damage the thread of the bolt, while using a drill that is too small will require a smaller and weaker retraction tip, which may break during removal.

- Since the retraction point is beveled, you will first use a hammer to knock it on the bolt, before attaching it to the T-handle or drill.

Remove broken bolts. While you drill the retraction bit into the bolt, torque is generated and will remove the bolt once the retraction head is firmly engaged in the bolt.

- Continue rotating the retraction tool counterclockwise until the broken bolt is completely removed from the surface of the object.

- Perform work slowly to prevent damage from occurring to the bolt or the object to which the bolt is attached. You should also work gently with the retractor, as it is made of hardened steel, so a broken tip is even more difficult to remove than a bolt.

Method 2 of 2: Use welding technique

Place the punching point in the center of the bolt body, as close to the center as possible. In the same way as using a bolt removal tool, you will use a hammer and a punch to mark the center of the bolt.

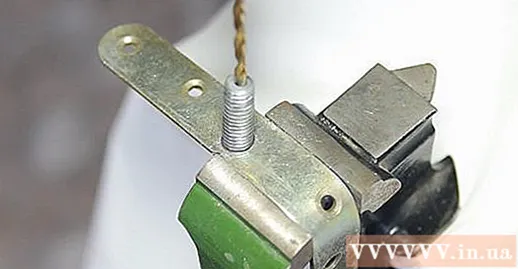

Drill a hole in the center of the bolt. Use a drill about a quarter of the bolt diameter and drill a guide hole.

- This method is usually for bolts that rust so badly that the removal tool cannot be used, so you don't have to worry about the bolts getting tightened by using a forward drill, but using a reverse drill is fine. than.

Solder nut to bolt. This is just a preliminary weld, but still requires a bit of welding experience. If you have never welded, you should ask someone who has experience in welding, or practice welding on another object first with online instructions.- Take particular care if the bolt-catching surface may melt onto the bolt or nut. For this reason, this method is best suited for aluminum surfaces because aluminum is not easily welded to steel.

Remove broken bolts. After the weld has cooled, the base nut has been permanently welded like the new end of the bolt so it can be screwed open with a tube key or wrench.

- The weld is quite hard but can still break. For bolts that are heavily rusted, the nut may have to be welded in multiple locations.

- In order to break the bond caused by corrosion, you should first turn back and forth very slowly. Once the bolts are loosened, continue to turn in both directions but turn more anti-clockwise, you will eventually remove the bolt.

Warning

- Work slowly with the retraction tip and do not apply excessive force. If you break the retraction zone in the bolt, you will need a drill that is harder than the steel of the retractor to remove it.

- Take necessary protective measures when using welding, including coats, protective masks, gloves, pants and boots.

- Wear safety glasses when drilling as metal filings can catch your eyes.

What you need

- Drill

- The drill bit in reverse

- Nose drawn

- Hand holding letter T

- Pliers

- magnet

- Hammer

- Punched nose

- Pneumatic

- Hex nut

- Welder

- Protective mask when welding

- Protective jacket when welding

- Gloves

- Safety glasses