Author:

Monica Porter

Date Of Creation:

18 March 2021

Update Date:

1 July 2024

Content

Making home soap is a great way to meet family needs or create great gifts for friends that are both satisfying and inexpensive. You can use soap making kits, but with making your own soap from scratch, you can choose your own ingredients and customize it to suit your needs. This article will show you how to make soap from basic ingredients using a cold method.

Resources

- 680 gr of coconut oil / olive oil

- 1,000 grams of vegetable fat

- 340 gr of sodium hydroxide or alkaline solution (also known as caustic soda)

- 900 gr of purified or distilled water

- 120 ml of your favorite essential oil, such as peppermint, lemon, rose or lavender

Steps

Part 1 of 4: Preparing to make soap using a cold method

Prepare materials. Cold soaps are made from oil, alkaline solutions, and water. When combined at the correct temperature, these materials harden into soap in a process called saponification. You can go to craft and grocery stores to buy the ingredients listed above.

Prepare the soap making area. Cleaning up a spot in the kitchen is easiest as you will need to heat the ingredients on the stove. You will need to dispose of alkali - a dangerous chemical, so be sure to keep children and pets away during the preparation. Spread newspaper on the table and prepare the following tools (can be purchased online or from a craft store):

- Goggles and rubber gloves to protect yourself from alkaline solutions.

- Scales for weighing ingredients.

- Stainless steel kettle or large porcelain pot. Do not use aluminum kettles and kettles with non-stick surfaces.

- Glass water jugs or large mouth plastic jugs for water and alkalis.

- Glass or plastic measuring beaker, of capacity 480 ml.

- Plastic spoon or wooden spoon.

- Hand blender. This is not strictly necessary, but it will reduce the time to stir the ingredients to about 30 minutes.

- Two glass thermometers can measure temperatures from 27-38 degrees Celsius. You can use a candy thermometer.

- The plastic mold is suitable for making cold soaps, or shoe boxes, or wooden molds. If you are using a shoebox or wooden mold, put it in a parchment.

- Lots of paper towels for cleaning.

Read how to use alkaline solutions safely. Before you start making soap, you should read the safety warning that comes with the lye solution. Remember the following when treating raw alkali or soap before drying:- Absolutely do not let alkaline solution stick to the skin because alkali causes skin burns.

- Always wear goggles and gloves while handling raw lye and soap.

- Dispose of alkaline solutions outside of your home or well-ventilated area to avoid inhaling up air.

Part 2 of 4: Mix the ingredients

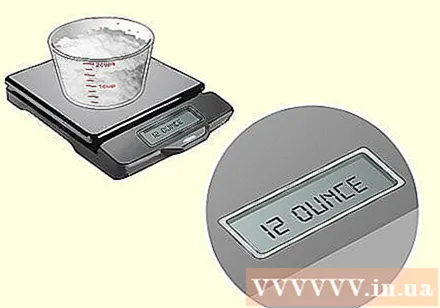

Weigh 340 gr of alkaline solution. Use a scale to ensure accurate weighing, then pour the lye solution into a 480 ml measuring beaker.

Weigh 900 gr of cold water. Use a scale to ensure accurate weighing, then pour water into a large container, such as a stainless steel pot or a glass bowl (do not use aluminum).

Fill the water with alkaline solution. Place the pot under the kitchen exhaust fan or open a window and secure the room. Slowly pour the alkaline solution into the water and stir gently with a spoon until completely dissolved.

- It is important to pour alkali into the water, not to do the opposite; If you put water in alkali, the reaction between the two is very rapid and can be dangerous.

- When alkali is added to water, the alkali heats the water and produces a gas. Turn away to avoid inhalation.

- Set the mixture aside. Wait for the mixture to cool and the substance when dissolved.

Measure the oil. Use a scale to weigh 680 grams of coconut oil, 1,000 grams of vegetable fat and 680 grams of olive oil.

Mix the oil. Place the large stainless steel pot on the stove over low heat. Fill a saucepan with coconut oil and vegetable fat and stir until melted. Add extra olive oil and stir until all ingredients are melted completely and evenly combined. Turn off the stove.

Measure the temperature of the alkaline solution and oil. Use a separate thermometer to measure the alkaline solution and oil. Continue monitoring until the alkaline solution reaches a temperature of 35-36 degrees C, while the oil reaches 35-36 degrees C or less.

Pour the alkaline solution into the oil. When the two mixes reach the right temperature, you can pour the alkaline solution slowly and evenly into the oil.

- Stir with a wooden spoon or heat-resistant spoon; Do not use metal spoons.

- You can use a hand blender to stir the alkaline solution and oil.

- Keep stirring for another 10-15 minutes until "streaking" occurs; You should see the spoon leave a clear streak, just like when making a pudding. If you are using a hand blender, this should take about 5 minutes.

- If you don't see the mixture streaking on the surface for 15 minutes, let it sit for 10-15 minutes before continuing to mix.

Add 120 ml of essential oil as the mixture starts to streak. Certain flavors and essential oils (e.g. cinnamon essential oil) harden the soap quickly, so be ready to pour the soap into the mold as soon as the essential oils are stirred in. advertisement

Part 3 of 4: Molded soap

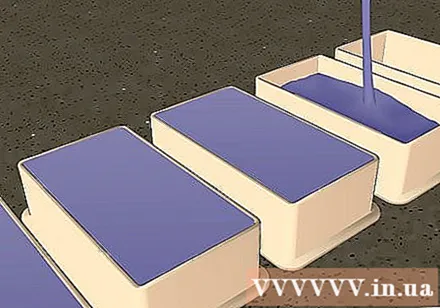

Pour soap into the mold. If you are using a shoe box or wooden mold, be sure to insert parchment paper in. Use an old plastic spatula to scrape the last remaining soap in the pot into the mold.

- Be sure to still wear gloves and goggles during this step as raw soap is corrosive and can cause skin burns.

- Carefully hold your face 2.5-5 cm from the table top and then drop it down. Do this a few times to push the air bubbles out of the raw soap.

Close the mold. If using a shoebox as a mold, you can put a lid on and cover with a few towels. If you are using a soap making mold, you can stick a piece of cardboard over it before covering it with a towel.

- The towel will help to isolate the soap and help with the saponification process.

- Cover, leave and keep soap away from exhaust fans (including air conditioners) for 24 hours.

Check the soap. The soap will undergo a gelatinization and heating process for 24 hours. Open the lid and let the soap stand for another 12 hours, then wait to see results.

- If measured correctly and according to the instructions, the soap will have a thin, white ash-like layer on its surface. This is essentially harmless and you can scrape it off with an old ruler or metal spatula.

- If the soap has a strong gloss above it cannot be used because the alkali and oil are separated. This occurs if you do not measure correctly, stir for not long enough, or if there is a significant difference between the temperature of the alkali and the oil when mixed.

- Soap that does not harden or has white or transparent particles in it means it can be corrosive to the skin and cannot be used. The reason is that there is not enough stir during the soap making process.

Part 4 of 4: Drying with soap

Remove the soap from the mold. Turn the box or mold upside down so the soap falls onto a clean towel or surface.

Cut the soap into pieces. You will need to use pressure to cut this soap. You can use a sharp knife, a long metal wire with two handles, a thick nylon thread or a fishing line.

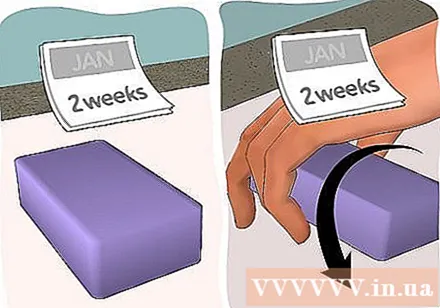

Dry the soap. Place the soap on a piece of parchment on a flat surface or stand for 2 weeks for saponification to complete and soap completely dry. Turn the soap over after 2 weeks to dry the other face.

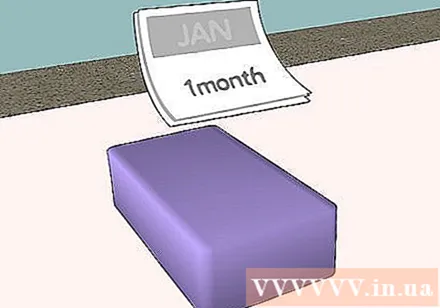

Leave soap for a month. Leave the soap in place and keep in contact with the air for at least a month. When the soap is completely dry, you can use it as commercial soap or as a gift for a friend. advertisement

Advice

- Do not use perfumes as fragrances, especially alcohol-based perfumes. Alcohol changes the chemical reaction between the alkaline and fat, causing the soap to spoil. You can use natural essential oils or special flavors to make soap. A little essential oil or fragrance also creates a very fragrant aroma. You only need to use about a teaspoon.

- Temperature is the key factor when mixing oil with alkali. If the temperature is too high, the two mixtures will separate; if the temperature is too low, the mixture does not become soap.

- You can buy alkaline solutions at most chemical stores or online stores. Make sure the product is 100% sodium hydroxide on the packaging.

- Do not make your own soap without the permission of your parent or guardian. If not, you might get in trouble.

Warning

- Soap making utensils are used only to make soap. Do not reuse in the kitchen or use for food handling. Be cautious when using wooden tools, as they are porous and may peel off if used for continuous soap making. Do not use a whisk, as caustics can adhere to many places on the tool.

- Small white particles that appear after the soap hardens in the mold is a sign that the soap is corrosive and must be handled safely. These white particles are alkaline. To treat this alkaline soap batch, you can neutralize the alkali with vinegar. Soak the soap cake in water and use your hands (gloved) to break the bar or use something else to break the soap into small pieces, then pour the soap-vinegar mixture down the drain .

- Alkaline solutions (sodium hydroxide) are strong bases and can be very dangerous. Avoid contact with skin and eyes. If the lye comes into contact with the skin, rinse with water, then use vinegar to neutralize the burn and seek medical attention. If the alkaline solution comes into contact with your eyes, rinse with cool water for 15-20 minutes and seek medical attention. Use an emergency eyewash or eye wash bottle if available. If alkaline solution is swallowed, contact a poison control center immediately.

- Wear rubber gloves and goggles when handling alkaline solutions. Do not keep alkaline solution out of reach of children and pets.

- When mixing chemicals such as alkali with water, you must always pour the chemicals into the water, not the chemicals to reduce the risk of chemical splashes.

What you need

- Oil:

- 680 gr of olive oil (not pure)

- 680 gr of coconut oil

- 1,000 grams of vegetable fat

- Lye:

- 340 gr of alkaline solution

- 900 gr of purified water or pure water

- Aromatherapy or essential oils

- 120 ml of favorite flavoring

- Device:

- Goggles

- Rubber gloves

- Apron

- Scales for weighing ingredients

- Stainless steel kettle or large porcelain pot. Do not use aluminum kettles and kettles with non-stick surfaces.

- Glass water jugs or large mouth plastic jugs for water and alkalis

- Glass or plastic measuring beaker, of capacity 480 ml

- Plastic spoon or wooden spoon

- Hand blender (optional)

- 2 glass thermometers can measure temperatures from 27-38 degrees Celsius. You can use a candy thermometer

- The plastic mold is suitable for making cold soap or shoebox or wooden molds.

- Stencils

- Lots of paper towels

- Flowing water and vinegar (in case of contact with alkaline solution).