Author:

Morris Wright

Date Of Creation:

25 April 2021

Update Date:

1 July 2024

Content

- To step

- Method 1 of 3: Install a retaining ring

- Method 2 of 3: Remove retaining rings

- Method 3 of 3: Choosing a retaining ring

- Necessities

- Edit

- Removal

Over time, bolts, nuts, and other screw fasteners can loosen due to friction and joint movement. Retaining rings are a type of hardware that, unlike regular washers, can hold these items in place. When properly installed, retaining rings are an inexpensive and easy way to keep screw fasteners stable over a long period of time.

To step

Method 1 of 3: Install a retaining ring

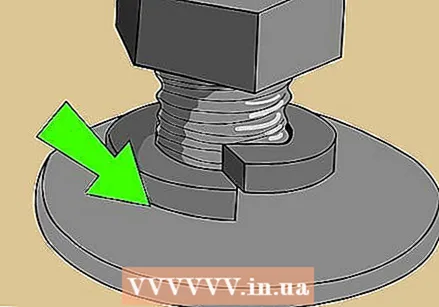

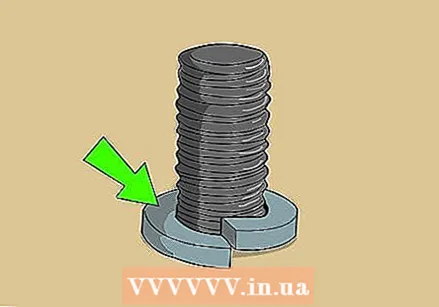

Place the retaining ring under the screw mounting. When used correctly, a lock washer will hold the nut or other screw fastener in place. To make this easier, put the locking ring underneath the mounting first. If other washers or hardware should be used for your job, they should be fitted in front of the retaining ring so that the retaining ring can hold them in place.

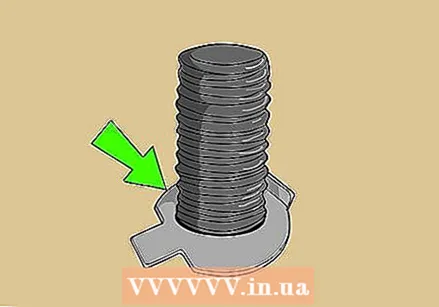

Place the retaining ring under the screw mounting. When used correctly, a lock washer will hold the nut or other screw fastener in place. To make this easier, put the locking ring underneath the mounting first. If other washers or hardware should be used for your job, they should be fitted in front of the retaining ring so that the retaining ring can hold them in place.  Make sure the retaining ring is firmly against the mount and the other surface. To work properly, the retaining ring must press against both the screw mount and the other adjacent surface, creating a tight connection. If the connection is not tight, press the fastener down until it is. This is especially important with lock nuts, where the grooves of the retaining ring must match the grooves of the nut.

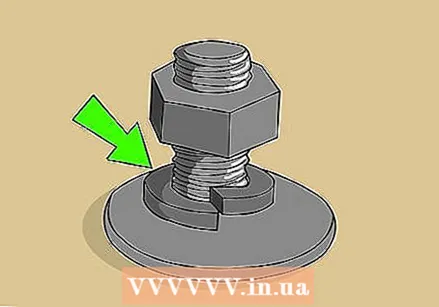

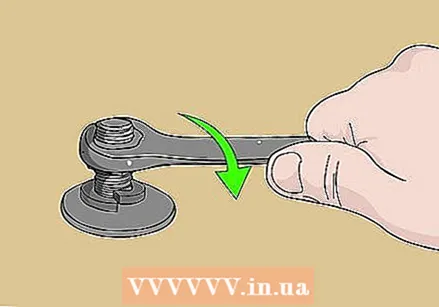

Make sure the retaining ring is firmly against the mount and the other surface. To work properly, the retaining ring must press against both the screw mount and the other adjacent surface, creating a tight connection. If the connection is not tight, press the fastener down until it is. This is especially important with lock nuts, where the grooves of the retaining ring must match the grooves of the nut.  Tighten the screw fastening. For small general jobs, tighten the nut or screw fastener clockwise with a wrench or ratchet. Do this until the fastener is secure, but can be loosened if necessary. For large or special jobs, refer to your project manual or the markings on the nut head for a specific torque value, then use a torque wrench to tighten the fastener to the specified amount.

Tighten the screw fastening. For small general jobs, tighten the nut or screw fastener clockwise with a wrench or ratchet. Do this until the fastener is secure, but can be loosened if necessary. For large or special jobs, refer to your project manual or the markings on the nut head for a specific torque value, then use a torque wrench to tighten the fastener to the specified amount.  Check the retaining ring to make sure it is working properly. Check that the teeth of the retaining ring are completely under the nut or the head of the mounting. With spring washers, you should check that the washer is slightly aligned, which indicates that it is applying tension to the screw mount. If the retaining ring is not working properly, loosen the nut or thread retainer and repair the retaining ring.

Check the retaining ring to make sure it is working properly. Check that the teeth of the retaining ring are completely under the nut or the head of the mounting. With spring washers, you should check that the washer is slightly aligned, which indicates that it is applying tension to the screw mount. If the retaining ring is not working properly, loosen the nut or thread retainer and repair the retaining ring.

Method 2 of 3: Remove retaining rings

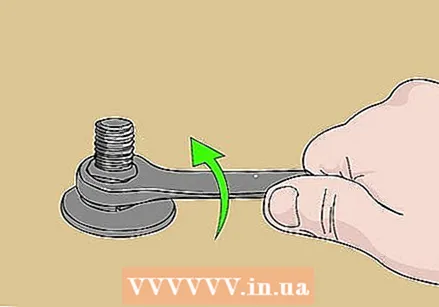

Remove the nut or screw fastener holding the retaining ring in place. For most nuts and fasteners, you can attach a simple wrench or locking pliers to the object and turn it counterclockwise. Stuck nuts and screw fasteners may require the use of a stronger tool, such as a pipe wrench, which you can tighten to the screw fastener and turn like a regular wrench.

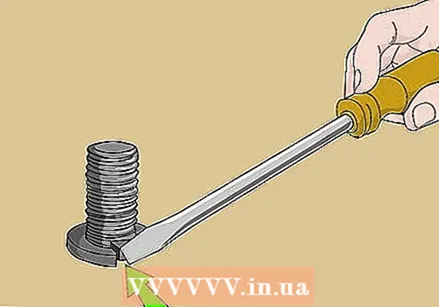

Remove the nut or screw fastener holding the retaining ring in place. For most nuts and fasteners, you can attach a simple wrench or locking pliers to the object and turn it counterclockwise. Stuck nuts and screw fasteners may require the use of a stronger tool, such as a pipe wrench, which you can tighten to the screw fastener and turn like a regular wrench.  Pry off the retaining ring with a flat screwdriver. When removing a spring washer, place the screwdriver head under the retaining ring or in the spring washer and then push. If you are removing a toothed retaining ring, place the screwdriver head under a tooth and push it up, using more teeth if necessary. For other rings, place the screwdriver head under the ring and push it up.

Pry off the retaining ring with a flat screwdriver. When removing a spring washer, place the screwdriver head under the retaining ring or in the spring washer and then push. If you are removing a toothed retaining ring, place the screwdriver head under a tooth and push it up, using more teeth if necessary. For other rings, place the screwdriver head under the ring and push it up. - Depending on the pressure under which the retaining ring is placed, it may break when removed.

Spray the retaining ring with lubricant if you can't get it off. If the retaining ring does not come off, spray the area with a penetrating lubricant such as WD-40 and Kroon oil. This will loosen the retaining ring and make it easier to remove. After applying the lubricant, repeat the previous step.

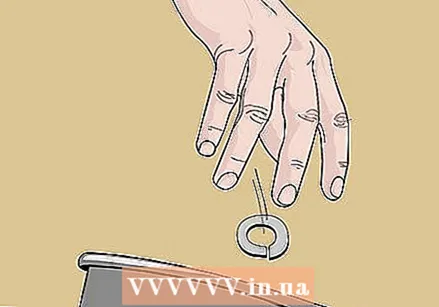

Spray the retaining ring with lubricant if you can't get it off. If the retaining ring does not come off, spray the area with a penetrating lubricant such as WD-40 and Kroon oil. This will loosen the retaining ring and make it easier to remove. After applying the lubricant, repeat the previous step.  Discard worn washers. Some retaining rings, such as knurled Bellevilles, can be used several times without problems. Other washers, such as spring washers, will wear out after one or two uses. For safety, do not reuse spring washers or washers that are damaged. Do not use old lock washers at all if you are dealing with high voltage connections.

Discard worn washers. Some retaining rings, such as knurled Bellevilles, can be used several times without problems. Other washers, such as spring washers, will wear out after one or two uses. For safety, do not reuse spring washers or washers that are damaged. Do not use old lock washers at all if you are dealing with high voltage connections.

Method 3 of 3: Choosing a retaining ring

Use a spring washer for small jobs. A spring washer, also known as a screw washer, is the most common type of washers. Rather than using grooves, it actually acts like a spring, holding the screw mount in place through friction. Use a spring washer for a small and low-intensity job, as greater loads will flatten the spring washer and render it useless.

Use a spring washer for small jobs. A spring washer, also known as a screw washer, is the most common type of washers. Rather than using grooves, it actually acts like a spring, holding the screw mount in place through friction. Use a spring washer for a small and low-intensity job, as greater loads will flatten the spring washer and render it useless.  Use serrated lock washers for extra strength. With their serrated edges, serrated lock washers hold the nut or screw fastener in place with a significant amount of force. They come in two forms: with internal teeth and with external teeth. Internal tooth lock washers work best on small screws or screws used in electrical grounding, while external tooth lock washers work best on large screws.

Use serrated lock washers for extra strength. With their serrated edges, serrated lock washers hold the nut or screw fastener in place with a significant amount of force. They come in two forms: with internal teeth and with external teeth. Internal tooth lock washers work best on small screws or screws used in electrical grounding, while external tooth lock washers work best on large screws. - Serrated lock washers work well on aluminum and soft plastic surfaces.

Choose a knurled Belleville washer for extremely stressed loads. Knurled Belleville Washers are conical pieces of hardware with grooves on the surface. They are used to distribute tension on a connection, and while they don't provide as much locking force as other retaining rings, they can be useful with extremely large and stressed loads.

Choose a knurled Belleville washer for extremely stressed loads. Knurled Belleville Washers are conical pieces of hardware with grooves on the surface. They are used to distribute tension on a connection, and while they don't provide as much locking force as other retaining rings, they can be useful with extremely large and stressed loads.  Choose a washer with tabs for harsh weather conditions. If the nut or screw fitting needs to withstand harsh weather conditions, choose a locking ring with tabs. These hardware have one or more tabs that, when bent against the head of the nut or the threaded fastener, hold it in place.

Choose a washer with tabs for harsh weather conditions. If the nut or screw fitting needs to withstand harsh weather conditions, choose a locking ring with tabs. These hardware have one or more tabs that, when bent against the head of the nut or the threaded fastener, hold it in place.

Necessities

Edit

- Nut or screw fixing

- Retaining ring

- Wrench or ratchet (for small jobs)

- Torque wrench (for large jobs)

Removal

- Wrench or locking pliers

- Flat screw driver

- Pipe wrench (for stuck washers)

- Spray can of lubricant (for stuck washers)