Author:

Gregory Harris

Date Of Creation:

11 August 2021

Update Date:

1 July 2024

Content

- Steps

- Method 1 of 2: Selecting the Right Brake Pads and Brake Pads

- Method 2 of 2: Mechanics of the Braking Process

- Warnings

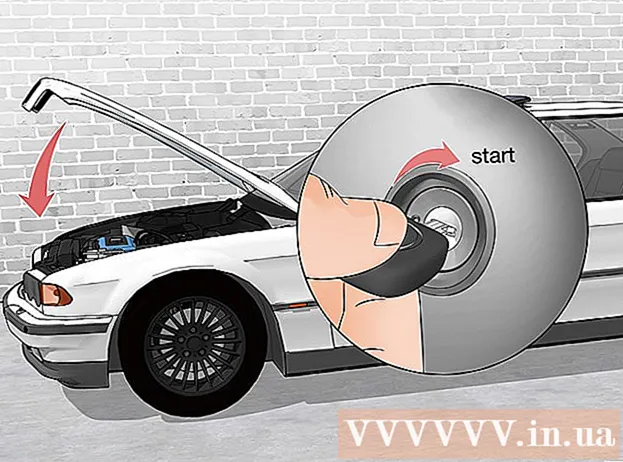

Sooner or later, you will have to decide on minor repairs to your car, especially in parts that are subject to regular wear and tear. Brakes, more precisely brake pads and pads, are the details on which your safety depends especially. The good news is that the plethora of brake pads and pads nowadays makes it relatively easy to choose the one that best suits your driving style and wallet.

Steps

Method 1 of 2: Selecting the Right Brake Pads and Brake Pads

- 1 Decide on the method of installing the lining on the shoe - riveting or gluing. All brakes are composed of a soft friction material attached to a stronger metal plate. Brake shoe manufacturers use two methods of attaching the friction material to the metal plate: gluing with a penetrating adhesive or installing with reinforced rivets.

- None of these methods have an absolute advantage, but when gluing the brakes last a little longer, because as the friction material wears out, the rivets begin to touch the brake discs or drums and creak when the brake pads are almost worn out. When you hear this creak, it is time to replace the brake pads.

- Glued brakes wear down to the metal backing, which usually leads to destruction of brake discs and drums if not replaced in time. With critical wear, you can hear the sound of metal rubbing against metal during braking.

- None of these methods have an absolute advantage, but when gluing the brakes last a little longer, because as the friction material wears out, the rivets begin to touch the brake discs or drums and creak when the brake pads are almost worn out. When you hear this creak, it is time to replace the brake pads.

2 When choosing a brake lining material, determine your preference as a driver. When buying new brake pads or pads, you need to decide on the material from which they are made. The decision must be made based on your braking requirements. Answer your own questions:

2 When choosing a brake lining material, determine your preference as a driver. When buying new brake pads or pads, you need to decide on the material from which they are made. The decision must be made based on your braking requirements. Answer your own questions: - How often do you drive in the mountains?

- How hot is the climate in which you live?

- What's your driving style?

- How tolerant are you of slightly squeaky brakes?

- Are you using a trailer?

- How often do you encounter deep puddles in winter or during rainy periods?

- 3 Choose between organic, semi-metallic, metallic and ceramic brake pads. Before making a final choice, you should once again weigh the pros and cons of this or that material.

- Organic: Some cars are equipped with brakes made from organic materials. They are “friendly” to brake details, but not good enough when towing a trailer or on long descents. In addition, organic pads show insufficient braking when exposed to moisture.

- Semi-metallic: This material is somewhat better for brakes. It is a combination of mild steel with friction material to improve braking performance. Unfortunately, such pads in disc and drum brakes wear out faster than those made from organic materials.

- Fully metal: More expensive, better quality and more efficient. All metal brakes are effective in all conditions, but they cause accelerated wear on brake discs and brake drums.

- Ceramic: The most expensive of all options, but the most durable and effective. Ceramic brakes can withstand very high temperatures and barely lose performance in wet conditions.

- Organic: Some cars are equipped with brakes made from organic materials. They are “friendly” to brake details, but not good enough when towing a trailer or on long descents. In addition, organic pads show insufficient braking when exposed to moisture.

- 4 Choose semi-metallic pads for a measured driving style. They are the best choice for commuter driving and they also have a very reasonable price.

- Most new cars come with OEM recommended semi-metallic pads. Even cars with very hard alloy disc brakes work just fine with semi-metallic brake pads.

- However, if you are using your vehicle for heavier tasks - such as towing a trailer or driving on mountain roads - it is better to opt for the more advanced all-metal or ceramic brakes.

- In other words, when choosing the right type of brake pads, you need to seriously consider your daily driving tasks, as well as determine how much effort is usually put on the brakes - your safety depends on it.

- Most new cars come with OEM recommended semi-metallic pads. Even cars with very hard alloy disc brakes work just fine with semi-metallic brake pads.

- 5 When replacing pads, inspect the entire brake system. It is reasonable to pay attention to it when doing self-repair or when working in an auto mechanic's workshop.

- The effectiveness of brake pads depends on the degree of wear of the brake discs, on which they create frictional friction and the main / working brake cylinders, which move the pads apart.

- It is also wise to replace the old brake fluid in the hydraulic system if your vehicle is over 8 years old. This is done to reduce the moisture content, which allows the brakes to perform at their best.

- The effectiveness of brake pads depends on the degree of wear of the brake discs, on which they create frictional friction and the main / working brake cylinders, which move the pads apart.

Method 2 of 2: Mechanics of the Braking Process

- 1 Understand the difference between brake pads and brake pads. These are two different parts. Brake linings are made for disc brakes - they are most often found on the front axles of cars and trucks. The brake pads are made for drum brakes that are mounted on the rear axles. ( * see footnote) The reason for the design difference can be found by analyzing the braking sequence:

- When you apply the brakes on your car, disc brake pads or brake pads should slow down the brake drums or discs installed between the rim and suspension elements. Friction that occurs when the brake discs are compressed by the brake linings or when the brake pads are extended towards the brake drum to brake the vehicle, the linings and pads become very hot.

- On long downhill gradients, the front brakes (and therefore the front brake linings) are subject to more stress than the rear brakes.Therefore, the front brakes require an excellent braking method to handle the additional load.

- When you apply the brakes on your car, disc brake pads or brake pads should slow down the brake drums or discs installed between the rim and suspension elements. Friction that occurs when the brake discs are compressed by the brake linings or when the brake pads are extended towards the brake drum to brake the vehicle, the linings and pads become very hot.

- 2 We need to understand why disc brakes are better than drum brakes. As we discussed above, disc brakes are located at the front of the car and are designed to withstand more stress than drum brakes at the rear. Therefore, they must be of better quality.

- Disc brakes were created by aircraft and race car designers looking for a better way to brake cars without catching fire on the brake pads. They were then used on the front axles of commercial vehicles to reduce front brake wear.

- On the other hand, the rear axle does not require the same amount of braking force. Because drum brakes are simpler and cheaper to manufacture, they have become a common type of rear brake on most buses and trucks.

- However, more and more powerful modern cars and heavy trucks usually have disc brakes on both axles (front and rear) due to their superior braking performance. Disc brakes also handle heat better than drum brakes, which means they work even when they're hot. Any braking system works worse when heated or wet, but disc brakes recover faster than drum brakes.

- Disc brakes were created by aircraft and race car designers looking for a better way to brake cars without catching fire on the brake pads. They were then used on the front axles of commercial vehicles to reduce front brake wear.

Warnings

- You shouldn't skimp on brake pads. Even a pile of scrap metal should stop quickly in front of a child on a bike or in front of a bus that stops in front of you in a blind turn. Good brake pads will help you to brake quickly and possibly save your life.