Author:

Alice Brown

Date Of Creation:

28 May 2021

Update Date:

1 July 2024

Content

Drilling an oil well is a laborious undertaking involving several groups of workers and specialists. Below are the key steps required to produce oil.

Steps

1 First, you need to hire geologists to analyze the area for oil.

1 First, you need to hire geologists to analyze the area for oil.- Geologists will analyze the surface, landscape, soil and rocks of the area, as well as analyze the magnetic and gravitational fields of the Earth.

- There are several methods for conducting seismic surveys, in which shock waves are directed into rock layers deep underground, and the results are then analyzed by specialists.

- The presence of hydrocarbons can be determined using electronic “noses” or, as they are also called, analyzers.

2 After the location for drilling is determined, it must be marked. For this, buoys are used if the place is under water. GPS coordinates are also used if the drilling site is on land.

2 After the location for drilling is determined, it must be marked. For this, buoys are used if the place is under water. GPS coordinates are also used if the drilling site is on land.  3 Complete all required legal procedures. Obtain any permits, leases and other documents required to start drilling. Assess any environmental impact that excavation in the area may have.

3 Complete all required legal procedures. Obtain any permits, leases and other documents required to start drilling. Assess any environmental impact that excavation in the area may have.  4 Clear and level the selected area.

4 Clear and level the selected area. 5 Make sure there is a water source nearby as water will be needed while drilling. If there is no water source nearby, it will need to be drilled.

5 Make sure there is a water source nearby as water will be needed while drilling. If there is no water source nearby, it will need to be drilled.  6 Additionally, dig a hole and surround it with a sturdy plastic grate. This pit will serve as a disposal site for drill cuttings and mud.

6 Additionally, dig a hole and surround it with a sturdy plastic grate. This pit will serve as a disposal site for drill cuttings and mud. - If drilling takes place in an environmentally sensitive area, then the cuttings and mud should be removed by trucks away from this area.

7 Dig a rectangular area near the proposed drilling site that will serve as a working platform for the drilling technician. Dig additional holes for equipment storage.

7 Dig a rectangular area near the proposed drilling site that will serve as a working platform for the drilling technician. Dig additional holes for equipment storage.

Method 1 of 2: Drilling a Main Well

1 Use a drill to drill a start hole that is shallower but wider than the main hole. Align this hole with a kelly.

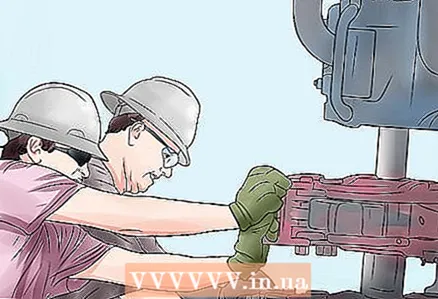

1 Use a drill to drill a start hole that is shallower but wider than the main hole. Align this hole with a kelly.  2 Continue drilling the main well with the oil rig. It is necessary to stop drilling when reaching the expected location of oil occurrence and install a bit, pipe collar and drill pipe in the well. Connect the kelly and rotor (the system that pumps the drilling fluid). Continue drilling, bringing the cut rock particles to the surface.

2 Continue drilling the main well with the oil rig. It is necessary to stop drilling when reaching the expected location of oil occurrence and install a bit, pipe collar and drill pipe in the well. Connect the kelly and rotor (the system that pumps the drilling fluid). Continue drilling, bringing the cut rock particles to the surface. - You can drill hundreds or thousands of meters deep before reaching the oil. To do this, it is necessary to build up the string of drill pipes and make intermediate fastenings with casing pipes so that you can move deeper.

3 Place the casing in the hole.

3 Place the casing in the hole. 4 Cement the hole to prevent the borehole wall from collapsing. Use a pump to pump cement and drilling fluid through the casing. Fill in the space between the walls of the pipe and the borehole itself and allow the cement to harden.

4 Cement the hole to prevent the borehole wall from collapsing. Use a pump to pump cement and drilling fluid through the casing. Fill in the space between the walls of the pipe and the borehole itself and allow the cement to harden.  5 Stop drilling when the cut rock particles show signs of oil sand from the rock formations being mined.

5 Stop drilling when the cut rock particles show signs of oil sand from the rock formations being mined. 6 Explore the recovered rock samples, measure the pressure, lower the gas sensors into the hole to determine if the reservoir has been reached.

6 Explore the recovered rock samples, measure the pressure, lower the gas sensors into the hole to determine if the reservoir has been reached.

Method 2 of 2: When Reservoir Is Reached

1 Lower the perforating gun to shoot small holes in the casing.

1 Lower the perforating gun to shoot small holes in the casing. 2 To bring oil and gas to the surface, lower the coiled tubing into the well.

2 To bring oil and gas to the surface, lower the coiled tubing into the well. 3 Seal the outside of the coiled tubing “with a packer.”

3 Seal the outside of the coiled tubing “with a packer.”  4 Control the flow of oil. Connect a multi-valve structure (called a "Christmas tree") to the top of the pipe.

4 Control the flow of oil. Connect a multi-valve structure (called a "Christmas tree") to the top of the pipe.  5 Dismantle the rig when oil starts flowing.

5 Dismantle the rig when oil starts flowing. 6 Install the pump at the wellhead.

6 Install the pump at the wellhead.

What do you need

- Specialists in underground geological research

- Equipment for seismology research

- Drillers team

- Boring machine

- Guide tube

- Casing

- Cement and pump

- Oil rig and drilling equipment