Author:

Gregory Harris

Date Of Creation:

11 August 2021

Update Date:

1 July 2024

Content

A brake caliper is a device that, when the brake pedal is depressed, presses the brake pad against the brake disc to stop the vehicle. Brake calipers can fail just like any other part of the brake system and, if so, will require replacement. In this guide, you will learn how to replace brake calipers.

Steps

- 1 Start by choosing the right tools to replace the calipers correctly. Start by loosening the wheel bolts (do not remove them) with a special wrench.

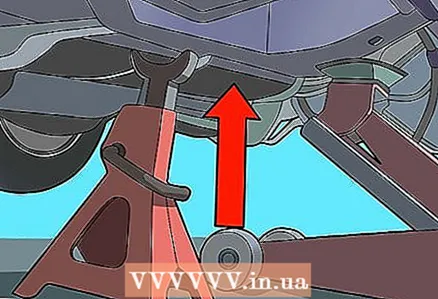

2 Raise the vehicle carefully with a jack. Make sure the jack is correctly positioned under the vehicle. You may want to support the machine with special stands. Check the vehicle manual for the jacking points.

2 Raise the vehicle carefully with a jack. Make sure the jack is correctly positioned under the vehicle. You may want to support the machine with special stands. Check the vehicle manual for the jacking points.  3 Take out the wheel bolts and remove the wheels. Turn the wheels so that the calipers can be easily reached.

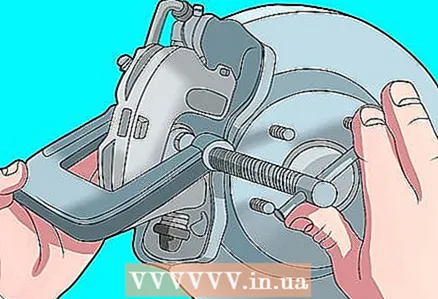

3 Take out the wheel bolts and remove the wheels. Turn the wheels so that the calipers can be easily reached.  4 Compress the caliper piston fully in the cylinder using a yoke or piston extraction tool.

4 Compress the caliper piston fully in the cylinder using a yoke or piston extraction tool. 5 You will need to have a container on hand to collect excess brake fluid. Remove the bolts holding the caliper hoses so that a wrench can be used.

5 You will need to have a container on hand to collect excess brake fluid. Remove the bolts holding the caliper hoses so that a wrench can be used. - Some machines may have clamps instead of bolts. Use a flat screwdriver to open them. Throw out old brass or copper washers. Never use old washers.

- 6 Insert a rubber plug into the hose to avoid leakage of brake fluid and contamination of the system. Never pinch brake hoses. This can cause damage, brake failure and an accident.

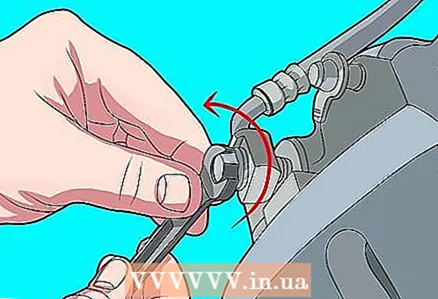

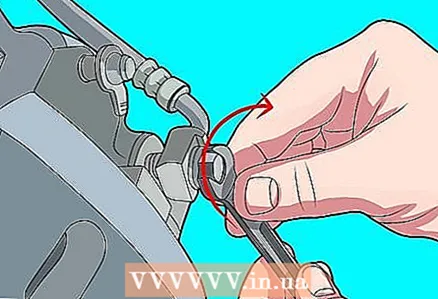

7 Loosen and remove the caliper retainer using a wrench. The figure shows the "banjo" fixation.

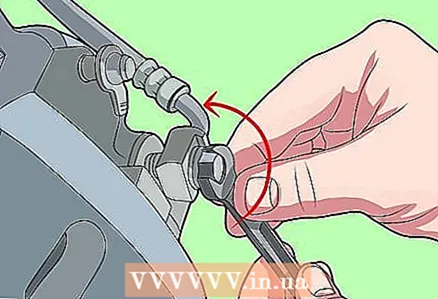

7 Loosen and remove the caliper retainer using a wrench. The figure shows the "banjo" fixation.  8 Remove the fixing bolts with a wrench. You will still need them, so save them. Some cars have 2 bolts, others have 1.

8 Remove the fixing bolts with a wrench. You will still need them, so save them. Some cars have 2 bolts, others have 1.  9 Raise the caliper until it opens the brake discs and then remove it. Carefully remove the brake pads from the caliper. Avoid dropping the brake pads as this can cause serious damage.

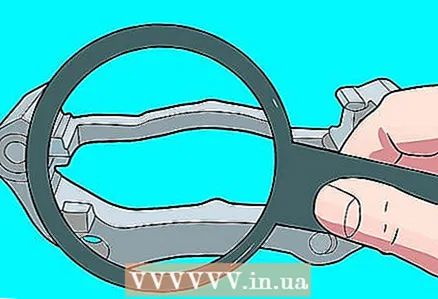

9 Raise the caliper until it opens the brake discs and then remove it. Carefully remove the brake pads from the caliper. Avoid dropping the brake pads as this can cause serious damage.  10 Examine the caliper supports for rust that may touch the new caliper. Remove any rust before installing a new caliper.

10 Examine the caliper supports for rust that may touch the new caliper. Remove any rust before installing a new caliper. - 11 Lubricate the rear of the brake pads, bushings and couplings with the recommended lubricant if recommended by the vehicle manufacturer. Install brake pads on new calipers if there are no pre-installed ones. Never lubricate the side of the pads that contacts the brake disc.

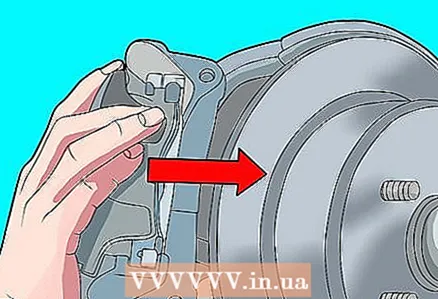

12 Carefully slide the brake pads and calipers onto the brake discs. Install new mounting bolts. If there are no new ones, use the old ones. Tighten the bolts according to the specifications of your machine. You may need a momentary key to do this. Do not overdo it with twisting!

12 Carefully slide the brake pads and calipers onto the brake discs. Install new mounting bolts. If there are no new ones, use the old ones. Tighten the bolts according to the specifications of your machine. You may need a momentary key to do this. Do not overdo it with twisting!  13 Reconnect the caliper hose using the banjo retainer and new washers. Tighten according to the characteristics of your machine.

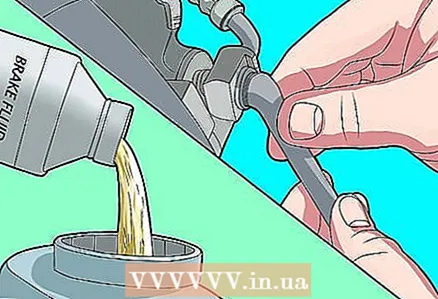

13 Reconnect the caliper hose using the banjo retainer and new washers. Tighten according to the characteristics of your machine. - 14 Remove the plug from the hose and replace the mounting bolts and clamps with a wrench.

15 Relieve pressure in the brake system until the brakes are secured. Top up with the correct brake fluid to replenish the lost volume.

15 Relieve pressure in the brake system until the brakes are secured. Top up with the correct brake fluid to replenish the lost volume.  16 Put the wheels back. Tighten the mounting bolts in a star-shaped pattern. Lower the vehicle carefully to the ground. After the vehicle is on its wheels, tighten the mounting bolts referring to the information in the vehicle manual. It is not recommended to use a pneumatic wrench without prior preparation.

16 Put the wheels back. Tighten the mounting bolts in a star-shaped pattern. Lower the vehicle carefully to the ground. After the vehicle is on its wheels, tighten the mounting bolts referring to the information in the vehicle manual. It is not recommended to use a pneumatic wrench without prior preparation.  17 Put your brakes to the test before you hit the road. If you have a feeling that the brakes are not working as they should, contact a certified technician urgently.

17 Put your brakes to the test before you hit the road. If you have a feeling that the brakes are not working as they should, contact a certified technician urgently.

Warnings

- Do not use compressed air to clean brake parts or crush brake pads, as asbestos dust that you can inhale can cause respiratory problems.

- Support the machine with props as needed. If the jack fails, you could be seriously injured.

What do you need

- Jack or props

- Wheel wrench or socket wrench.

- Moment key

- Regular wrenches (size depends on the vehicle)

- Flat screwdrivers

- Rubber plugs

- Staple or tool for removing pistons