Author:

Alice Brown

Date Of Creation:

25 May 2021

Update Date:

1 July 2024

Content

- Steps

- Method 1 of 4: Using a regular screwdriver

- Method 2 of 4: Using an impact screwdriver

- Method 3 of 4: Using an extractor

- Method 4 of 4: Complementary Methods

- Tips

- Warnings

- What do you need

- Additional articles

If the screwdriver constantly slips in the head of the screw, you need to create additional friction between it and the head, or apply more torque. There are many simple ways to remove a screw with the help of available household materials. Of course, you need special tools for tightly locked screws, but they are not so expensive and are always on sale.

Steps

Method 1 of 4: Using a regular screwdriver

1 Maximize the grip of the screwdriver with the screw. If the head of the screw is not yet completely ripped off and the screwdriver is still clinging to it, try to unscrew the screw by hand one last time. To increase your chances of success, follow the instructions below.

1 Maximize the grip of the screwdriver with the screw. If the head of the screw is not yet completely ripped off and the screwdriver is still clinging to it, try to unscrew the screw by hand one last time. To increase your chances of success, follow the instructions below. - If the screw is screwed into the metal, apply an impregnating oil to it and let it sit for at least 15 minutes.

- Get the largest screwdriver that fits your screw.

- If possible, grip the screwdriver handle with a wrench to use additional leverage.

2 Use auxiliary materials to increase the frictional force. If the screwdriver slips stubbornly in the damaged screw head, cover the screw with a small piece of material that will provide a better grip between the screwdriver and the head. Place a screwdriver against the head through this material and try to remove the screw again. The following can be used as auxiliary materials:

2 Use auxiliary materials to increase the frictional force. If the screwdriver slips stubbornly in the damaged screw head, cover the screw with a small piece of material that will provide a better grip between the screwdriver and the head. Place a screwdriver against the head through this material and try to remove the screw again. The following can be used as auxiliary materials: - wide cut elastic band (to make a strip of rubber);

- a piece of steel wool;

- a piece of green abrasive kitchen sponge;

- scotch tape (with the adhesive side to the screw head).

3 Hit the screwdriver lightly so that it fits correctly into the slots. Hit the screwdriver carefully to avoid accidentally breaking the screw head. If you are working with a fragile object, skip this step.

3 Hit the screwdriver lightly so that it fits correctly into the slots. Hit the screwdriver carefully to avoid accidentally breaking the screw head. If you are working with a fragile object, skip this step.  4 Press down firmly on the screwdriver while rotating. Grasp the handle of the screwdriver with your palm and place your forearm in line with the screwdriver. Press down firmly on the screwdriver with your hand as it rotates.

4 Press down firmly on the screwdriver while rotating. Grasp the handle of the screwdriver with your palm and place your forearm in line with the screwdriver. Press down firmly on the screwdriver with your hand as it rotates. - If the screwdriver slips into the head again, stop immediately. Further scrolling the screwdriver in the head will only deform it even more and complicate the process of removing the screw.Be sure to check that you are turning in the correct direction when removing the screw. Usually (but not always), to unscrew the screw, it should be turned counterclockwise (unscrew it to the left, and tighten it to the right). Strong pressure on the screwdriver itself prevents it from slipping in the head.

5 Heat the problematic screw. If you can heat a problem screw without harming the object it is screwed into, this will help loosen the grip of the thread. Heat the screw with a hot air gun or a gas burner, moving the fixture constantly to avoid overheating. As soon as the screw gets so hot that a drop of water that falls on it will immediately begin to hiss, leave it to cool, and then try to unscrew it again.

5 Heat the problematic screw. If you can heat a problem screw without harming the object it is screwed into, this will help loosen the grip of the thread. Heat the screw with a hot air gun or a gas burner, moving the fixture constantly to avoid overheating. As soon as the screw gets so hot that a drop of water that falls on it will immediately begin to hiss, leave it to cool, and then try to unscrew it again. - This is especially helpful when the screw is screwed in with a bonding agent or adhesive.

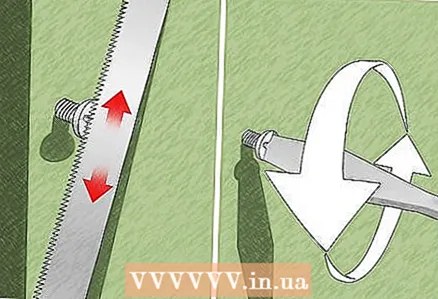

6 Use a hacksaw to cut a slot in the screw head for a flathead screwdriver. If you still cannot move the screw from its place, cut a groove in its head. Then insert a flathead screwdriver into the slot and try to remove the screw. This step can be combined with any of the above steps.

6 Use a hacksaw to cut a slot in the screw head for a flathead screwdriver. If you still cannot move the screw from its place, cut a groove in its head. Then insert a flathead screwdriver into the slot and try to remove the screw. This step can be combined with any of the above steps.

Method 2 of 4: Using an impact screwdriver

1 Take an impact screwdriver. An impact screwdriver is a hand-held tool, the point of which cuts deeper into the screw head due to the action of force and spring. This screwdriver works well for sturdy building structures, but it can damage electronics and fragile equipment. If you are concerned about damaging an object with a stuck screw, ditch the cheap heavy-spring screwdrivers as they require more hammer blows.

1 Take an impact screwdriver. An impact screwdriver is a hand-held tool, the point of which cuts deeper into the screw head due to the action of force and spring. This screwdriver works well for sturdy building structures, but it can damage electronics and fragile equipment. If you are concerned about damaging an object with a stuck screw, ditch the cheap heavy-spring screwdrivers as they require more hammer blows. - It is also not recommended to use an electric impact screwdriver, as excessive force can damage the surface into which the screw is screwed.

2 Adjust the screwdriver to loosen the screws. Some screwdriver models have a switch. In other models, the direction of rotation is set by turning the handle of the screwdriver.

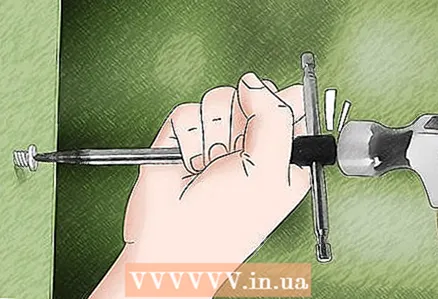

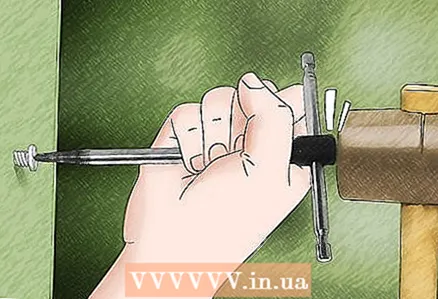

2 Adjust the screwdriver to loosen the screws. Some screwdriver models have a switch. In other models, the direction of rotation is set by turning the handle of the screwdriver.  3 Attach a screwdriver to the head of the screw. Insert the correct size bit into the screwdriver. Attach the screwdriver to the screw and hold it strictly at a 90º angle to the plane of the head. Grasp the middle of the screwdriver handle so that the end of the handle is free.

3 Attach a screwdriver to the head of the screw. Insert the correct size bit into the screwdriver. Attach the screwdriver to the screw and hold it strictly at a 90º angle to the plane of the head. Grasp the middle of the screwdriver handle so that the end of the handle is free. - The bits that come with impact screwdrivers are usually very durable, making the job easier.

4 Hit the screwdriver with a mallet. Hit the screwdriver handle firmly with a heavy mallet. A rubber mallet will help prevent scratches on the screwdriver handle.

4 Hit the screwdriver with a mallet. Hit the screwdriver handle firmly with a heavy mallet. A rubber mallet will help prevent scratches on the screwdriver handle.  5 Check the direction of rotation of the screwdriver. Some impact screwdrivers reset the rotation setting after each impact. If the setting is reset, move it back to the unscrewed position.

5 Check the direction of rotation of the screwdriver. Some impact screwdrivers reset the rotation setting after each impact. If the setting is reset, move it back to the unscrewed position.  6 Repeat the procedure until the screw gives way. As soon as the screw starts to loosen, go to a regular screwdriver and unscrew it from the hole.

6 Repeat the procedure until the screw gives way. As soon as the screw starts to loosen, go to a regular screwdriver and unscrew it from the hole.

Method 3 of 4: Using an extractor

1 Take an extractor to remove the torn off screws. If the screw head is ripped off but is intact, buy a screw extractor to remove the torn off screws. A conventional extractor is a kind of extra hard metal screwdriver with a reverse thread on the tip. It is one of the most reliable tools for removing stripped screws, but it should be used with care. If the extractor breaks off right in the cap, then it will be possible to remove the screw only with the help of professionals. To reduce the chance of tool breakage, select an extractor with a diameter of no more than 75% of the screw shank (not the head).

1 Take an extractor to remove the torn off screws. If the screw head is ripped off but is intact, buy a screw extractor to remove the torn off screws. A conventional extractor is a kind of extra hard metal screwdriver with a reverse thread on the tip. It is one of the most reliable tools for removing stripped screws, but it should be used with care. If the extractor breaks off right in the cap, then it will be possible to remove the screw only with the help of professionals. To reduce the chance of tool breakage, select an extractor with a diameter of no more than 75% of the screw shank (not the head). - For screws with a star or hex slot and a protruding cylindrical body, use the special multi-groove extractor. It fits well into the cap and is fixed on its inner surface with the help of numerous notches.Instead of following the directions below, simply tap gently on the extractor plugged into the bonnet and turn it with a box wrench.

2 Place a hole in the center of the screw head. Place the center punch exactly in the center of the screw head. Hit the center punch with a hammer to make a notch for the drill setting.

2 Place a hole in the center of the screw head. Place the center punch exactly in the center of the screw head. Hit the center punch with a hammer to make a notch for the drill setting. - Use eye protection against flying metal filings. Do not remove protection until the very end of work.

3 Drill a hole in the screw head. Get a quality drill designed for drilling in hard metals. The extractor must be marked with a suitable drill size. Drill slowly and evenly (use a drill if possible). First, drill a hole 3-6 mm deep. If the hole is too deep, the screw may break. It is a good idea to start drilling the screw with a thinner drill, so that later it will be easier to work with a thicker one.

3 Drill a hole in the screw head. Get a quality drill designed for drilling in hard metals. The extractor must be marked with a suitable drill size. Drill slowly and evenly (use a drill if possible). First, drill a hole 3-6 mm deep. If the hole is too deep, the screw may break. It is a good idea to start drilling the screw with a thinner drill, so that later it will be easier to work with a thicker one.  4 Hit the extractor in the hole with a brass hammer. The hardened metal of the extractor is brittle enough that an iron or steel hammer can break it. Tap the extractor until it snaps securely into the drilled hole.

4 Hit the extractor in the hole with a brass hammer. The hardened metal of the extractor is brittle enough that an iron or steel hammer can break it. Tap the extractor until it snaps securely into the drilled hole.  5 Rotate the extractor carefully. If the torque is too sharp or uneven, the extractor may break, aggravating the situation. The safest way to unscrew the screw with the extractor is to use the handle supplied with it. The drilling itself should already have loosened the screw, so it should be unscrewed without much effort.

5 Rotate the extractor carefully. If the torque is too sharp or uneven, the extractor may break, aggravating the situation. The safest way to unscrew the screw with the extractor is to use the handle supplied with it. The drilling itself should already have loosened the screw, so it should be unscrewed without much effort. - Some extractor kits have a hexagonal non-working end. Grasp this end with two wrenches, positioning them 180º apart to distribute the force evenly.

6 Heat the screw if it won't give way. If the screw does not come out or you are afraid of breaking the extractor, remove the tool. Heat the screw with a torch and then drip it with paraffin or plain water to lubricate the threads. When the screw has cooled down, try using the extractor again.

6 Heat the screw if it won't give way. If the screw does not come out or you are afraid of breaking the extractor, remove the tool. Heat the screw with a torch and then drip it with paraffin or plain water to lubricate the threads. When the screw has cooled down, try using the extractor again. - Be careful not to damage nearby surfaces. Even when working with metal objects, it is best to use a hair dryer or gas burner. Move the heating device constantly, do not stay in one place for more than a second.

Method 4 of 4: Complementary Methods

1 Using epoxy glue, glue the nut to the screw head. Find a nut that fits snugly over the screw head. Glue the cap and nut together with epoxy metal glue, often referred to as "cold welding". Wait for the glue to harden, then place a wrench over the nut and twist.

1 Using epoxy glue, glue the nut to the screw head. Find a nut that fits snugly over the screw head. Glue the cap and nut together with epoxy metal glue, often referred to as "cold welding". Wait for the glue to harden, then place a wrench over the nut and twist. - If you do not have a nut of the correct size, you can glue a smaller nut on top of the head of the screw, but this connection will no longer be as strong.

2 Reamer the screw head completely. Drilling a hole in a screw often allows you to relieve the pressure on its rod and unscrew it, but if you failed to do this, then for further actions you have practically no choice. Use a drill bit slightly larger than the screw shank so that the screw head falls off when you drill it out. First, make a serif exactly in the center of the cap, and then drill it out in this place. As soon as the screw head falls off, grab the sticking out screw shaft with pliers and start rotating it counterclockwise to unscrew it.

2 Reamer the screw head completely. Drilling a hole in a screw often allows you to relieve the pressure on its rod and unscrew it, but if you failed to do this, then for further actions you have practically no choice. Use a drill bit slightly larger than the screw shank so that the screw head falls off when you drill it out. First, make a serif exactly in the center of the cap, and then drill it out in this place. As soon as the screw head falls off, grab the sticking out screw shaft with pliers and start rotating it counterclockwise to unscrew it. - If the head of the screw is not flat, grind it off with a grinding attachment for a drill. Once the hat is flat, roll the center over and re-drill it.

3 Hire a professional. If all your efforts have gone to waste, hire a craftsman who can remove the screw using an EDM machine. This is often the only way out in the event that the extractor breaks off in the screw head.

3 Hire a professional. If all your efforts have gone to waste, hire a craftsman who can remove the screw using an EDM machine. This is often the only way out in the event that the extractor breaks off in the screw head.

Tips

- If you can inspect the underside of the surface the screw is in, check to see if it is sticking out there. If this is the case, you can use a pair of pliers or a box wrench to grab the end of the screw and twist it from the inside to the outside.

- Make sure to rotate the screw in the correct direction. The screw may have a reverse thread, which requires clockwise rotation to remove it.

- If the hole left after the screw is damaged, then the situation can be corrected in several ways.

- Cut a larger diameter thread in the hole. Then lubricate the hole with sealant for security and screw a suitable wire liner into the hole.

- Screw the larger self-tapping screw into the hole.

- Use a bolt and nut. To secure metal objects to a hole in the metal, a nut can be welded to create a stationary screw attachment point.

Warnings

- Metal burrs on stripped screws can injure you and cause temporary disability.

What do you need

- Screwdriver

- An extractor for removing torn screws or a whole set of extractors (in a tool store, the price of these products can vary from several hundred to several thousand rubles)

- Box wrench

- Electric drill

- Drill for metal

- Eye protection

- Work gloves

- Normal hammer or mallet

- Impact screwdriver

- Hacksaw

- Pliers

- Scotch tape, elastic band, steel wool or abrasive material

Additional articles

How to drill holes in concrete

How to drill holes in concrete  How to make a skateboard ramp How to set up a wooden fence post

How to make a skateboard ramp How to set up a wooden fence post  How to fill a hole in an asphalt road

How to fill a hole in an asphalt road  How to cover grout with sealant

How to cover grout with sealant  How to install piles in water for a dock or pier

How to install piles in water for a dock or pier  How to remove a broken screw

How to remove a broken screw  How to make concrete bricks

How to make concrete bricks  How to create artificial stones from concrete

How to create artificial stones from concrete  How to break concrete

How to break concrete  How to build a terrace around an above ground pool How to cut PVC pipes

How to build a terrace around an above ground pool How to cut PVC pipes  How to sink a screw head into wood

How to sink a screw head into wood  How to work with sandpaper

How to work with sandpaper