Author:

Eric Farmer

Date Of Creation:

4 March 2021

Update Date:

27 June 2024

Content

- Steps

- Method 1 of 2: How to use the solder suction

- Method 2 of 2: How to use a braid to remove the solder

- Warnings

- What do you need

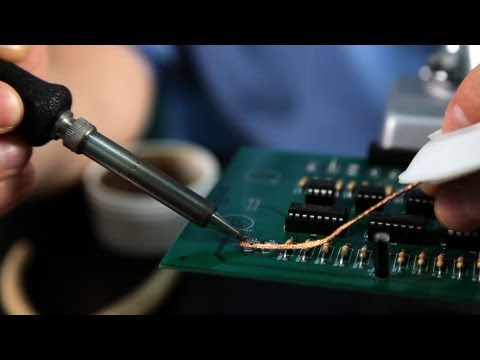

To repair or replace electronic components on a circuit board, you may need to unsolder the connections to remove them. You can use one of the two most popular methods: a solder suction (or desoldering pump) or a braid to remove the solder.

Steps

Method 1 of 2: How to use the solder suction

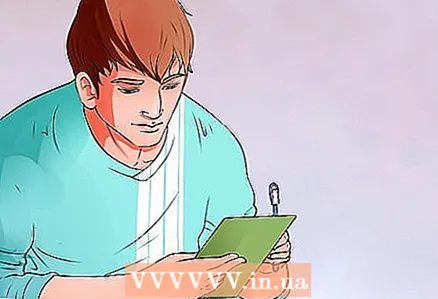

1 Find the contact points for the component to be removed. Desoldering pump is usually used when it is necessary to remove the soldered components on the board by desoldering the piece holding the component to the board. By carefully examining both sides of the board, you can identify the exact mounting locations for the component.

1 Find the contact points for the component to be removed. Desoldering pump is usually used when it is necessary to remove the soldered components on the board by desoldering the piece holding the component to the board. By carefully examining both sides of the board, you can identify the exact mounting locations for the component. - You can easily ruin a circuit board if you accidentally separate the board layers while removing the solder, so make sure you unsolder the marked pins required to remove the defective component.

2 Clean your contacts. Using isopropyl alcohol on your toothbrush, gently brush the contacts of the component you want to remove. Clean only the pins that are on the soldered side of the board, not the component side.

2 Clean your contacts. Using isopropyl alcohol on your toothbrush, gently brush the contacts of the component you want to remove. Clean only the pins that are on the soldered side of the board, not the component side.  3 Clean the soldering iron when it gets hot. Quickly run a damp sponge from the base to the tip of the soldering iron to clean it.

3 Clean the soldering iron when it gets hot. Quickly run a damp sponge from the base to the tip of the soldering iron to clean it. - When rubbing with a sponge, you may notice a little smoke, but that's just from the moisture on the sponge.

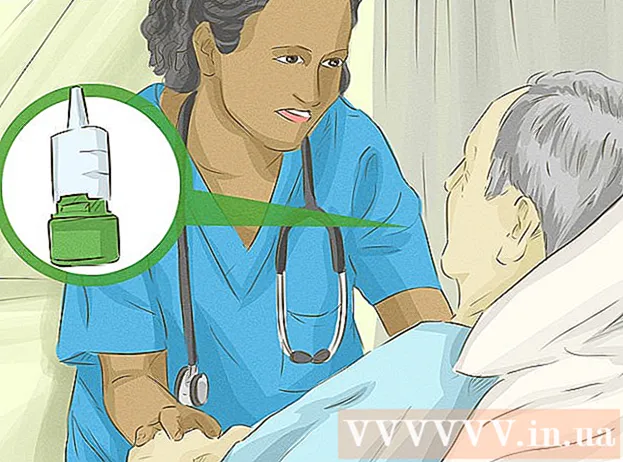

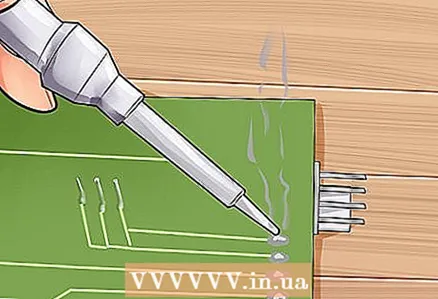

4 Heat up the old solder with a soldering iron. Heat the old solder by placing the tip of the soldering iron on the contact until it melts enough to be sucked in by the desoldering pump. Pressing down on the contact while soldering with a soldering iron can also release the component when the old solder melts.

4 Heat up the old solder with a soldering iron. Heat the old solder by placing the tip of the soldering iron on the contact until it melts enough to be sucked in by the desoldering pump. Pressing down on the contact while soldering with a soldering iron can also release the component when the old solder melts. - If you have an old soldering iron, you might want to use it for this particular job, since pushing the contacts while soldering will cause additional wear on the soldering iron.

- If the old, hardened solder does not want to melt, then you can get off the ground with a new piece of solder, but you need to quickly remove the mixture so that you do not have to remove even more when it hardens.

5 Remove the molten solder using a desoldering pump. The desoldering pump is a spring-loaded sealed tube that can safely suck the molten solder from the circuit board.Place the tip of the desoldering pump over the contact when squeezing the desoldering pump spring and immediately after the old solder has melted, then release the spring to suck in the old solder.

5 Remove the molten solder using a desoldering pump. The desoldering pump is a spring-loaded sealed tube that can safely suck the molten solder from the circuit board.Place the tip of the desoldering pump over the contact when squeezing the desoldering pump spring and immediately after the old solder has melted, then release the spring to suck in the old solder. - It is advisable to immediately clean the molten solder tube after each cleaned contact following the instructions for your specific desoldering pump model. Otherwise, old solder may leak back when you suck on the next contact.

- Contacting, especially with old solder, may require the use of a soldering iron and a pump several times before the component can be released. Once the solder is removed, you can also gently rock the component from the opposite side to help release it.

- Depending on the rate at which the molten solder cools, you may need to melt one contact at a time, rather than several at once, before attempting to suck them in. For this method to be as effective as possible, you need to hold the soldering iron in one hand and a ready-to-use desoldering pump in the other.

Method 2 of 2: How to use a braid to remove the solder

1 Find the pins of the component you want to remove. Just as with a desoldering pump, you need to find the exact contact points that need to be unsoldered in order to remove the required component. Check both sides of the board to find the pins you need to desolder.

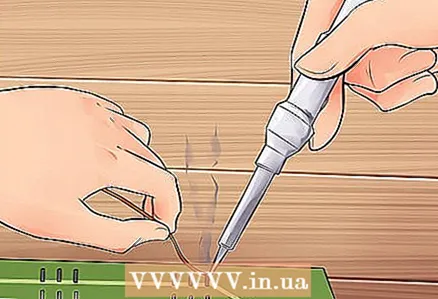

1 Find the pins of the component you want to remove. Just as with a desoldering pump, you need to find the exact contact points that need to be unsoldered in order to remove the required component. Check both sides of the board to find the pins you need to desolder.  2 Heat up the soldering iron. After you plug in the soldering iron and heat it up, it will be helpful to melt a small piece of solder wire on the tip of the soldering iron. The new piece of solder will mix with the old solder joint when both melt, which will help the braid absorb the old, molten solder.

2 Heat up the soldering iron. After you plug in the soldering iron and heat it up, it will be helpful to melt a small piece of solder wire on the tip of the soldering iron. The new piece of solder will mix with the old solder joint when both melt, which will help the braid absorb the old, molten solder.  3 Touch the molten solder to the contact. This process will accelerate the melting of the contact.

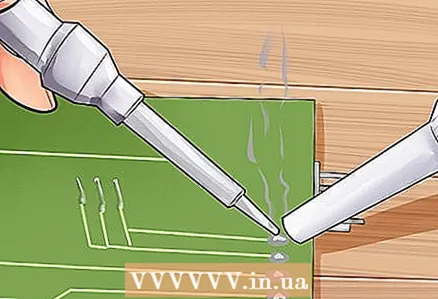

3 Touch the molten solder to the contact. This process will accelerate the melting of the contact.  4 Place the solder removal braid on the contact. A desoldering braid (also known as a desoldering braid) is a thin braid of copper strands that, when placed over molten solder, is capable of absorbing molten material. Place the tip of the soldering iron over the brazing braid over the contact to keep the solder melted and sucked.

4 Place the solder removal braid on the contact. A desoldering braid (also known as a desoldering braid) is a thin braid of copper strands that, when placed over molten solder, is capable of absorbing molten material. Place the tip of the soldering iron over the brazing braid over the contact to keep the solder melted and sucked.  5 Wait until the solder is completely absorbed by the braid. It may take a few seconds for the braid to absorb the molten solder.

5 Wait until the solder is completely absorbed by the braid. It may take a few seconds for the braid to absorb the molten solder. - The braid removal braid is fluxed and will no longer suck in molten solder after a single use, so you will need to unwind a piece of new braid if you unsolder multiple contacts.

- Always hold onto the coil the braid is wrapped around, as copper conducts heat and you can burn yourself if you hold onto it directly.

6 Wait for the heated part to cool down. When the contact holding the component has cooled down after about thirty seconds, you should easily remove the part.

6 Wait for the heated part to cool down. When the contact holding the component has cooled down after about thirty seconds, you should easily remove the part.  7 If necessary, use a braid for desoldering on both sides of the board. If the board is covered with metal on both sides and has metal through holes, then braiding on only one side may not release the contact. In this case, repeat the same steps on the PCB from the component side, taking additional precautions so that the braid and soldering iron do not touch the components, but only the solder to be removed. Once both sides of each through-hole have been cleaned, the part should be easily removed from the board.

7 If necessary, use a braid for desoldering on both sides of the board. If the board is covered with metal on both sides and has metal through holes, then braiding on only one side may not release the contact. In this case, repeat the same steps on the PCB from the component side, taking additional precautions so that the braid and soldering iron do not touch the components, but only the solder to be removed. Once both sides of each through-hole have been cleaned, the part should be easily removed from the board.

Warnings

- Soldering irons are hot! Always use extreme caution when handling your soldering iron.

- Fumes from lead-based solder can be very harmful. Drink in a well-ventilated area and wear suitable eye and respiratory protection.

- When using the braid to remove the solder, hold onto the spool that it is wrapped around as the copper braid itself conducts heat.

- The spring-loading mechanism of some desoldering pumps sometimes looses and can harm your eyes, so always point the back of the pump away from your face.

What do you need

- Soldering iron

- Solder Removal Braid

- Solder wire

- Cleaning sponge

- Desoldering pump

- Eye and respiratory protection

- Isopropyl alcohol

- Toothbrush