Author:

William Ramirez

Date Of Creation:

19 September 2021

Update Date:

1 July 2024

Content

- Steps

- Part 1 of 3: Preparation and first coat of plaster

- Part 2 of 3: Laying the Stone

- Part 3 of 3: Final finishing

- Tips

- Warnings

Stone wall cladding is a great way to enhance the interior and / or exterior of your home or any other building. For such a versatile and unpretentious improvement, you only need a few simple tools and hands-on knowledge that almost everyone has access to. Almost any stone cladding is made from the same materials, the process is also the same. And our tips will help you figure it out.

Steps

Part 1 of 3: Preparation and first coat of plaster

1 Surface preparation. Stone cladding can be applied to any stone surface such as concrete, brick wall or cinder block foundation. If you are working with wood or any other non-stone surface, then you will need to waterproof it.

1 Surface preparation. Stone cladding can be applied to any stone surface such as concrete, brick wall or cinder block foundation. If you are working with wood or any other non-stone surface, then you will need to waterproof it.  2 Apply a waterproofing layer. The waterproofing layer is usually supplied with a self-sealing membrane. Peel off the outer layer to expose the adhesive backing of the membrane and simply glue it to your surface.

2 Apply a waterproofing layer. The waterproofing layer is usually supplied with a self-sealing membrane. Peel off the outer layer to expose the adhesive backing of the membrane and simply glue it to your surface. - Be careful to apply the membrane only where it is needed. The membrane lining is very strong; if it accidentally sticks in the wrong place, then it will be very problematic to peel it off.

- When cladding an interior, a waterproofing layer is required only when working with a wooden surface such as plywood.

3 After the waterproofing layer, a fine metal mesh is installed. Use nails 3.8 - 5 cm and place them 15 cm apart.

3 After the waterproofing layer, a fine metal mesh is installed. Use nails 3.8 - 5 cm and place them 15 cm apart.  4 Apply the first coat of plaster. To make a mortar, mix 2 or 3 parts of washed sand with 1 part of cement, add water according to the manufacturer's instructions. Using a trowel, apply the solution to the entire surface of the mesh with a layer thickness of 1.5 - 2 cm. The mesh should not stick out of the plaster.

4 Apply the first coat of plaster. To make a mortar, mix 2 or 3 parts of washed sand with 1 part of cement, add water according to the manufacturer's instructions. Using a trowel, apply the solution to the entire surface of the mesh with a layer thickness of 1.5 - 2 cm. The mesh should not stick out of the plaster. - Mixing instructions may vary. Observe the manufacturer's instructions, but first of all strictly adhere to the selected recipe.If using a 2: 1 ratio of sand and cement, stick to it throughout all work.

5 Scratch horizontally before the first layer of plaster dries. For this purpose, use a metal scraper or a discarded piece of mesh. Then let the mortar set according to the manufacturer's directions. Now everything is ready for the stone cladding.

5 Scratch horizontally before the first layer of plaster dries. For this purpose, use a metal scraper or a discarded piece of mesh. Then let the mortar set according to the manufacturer's directions. Now everything is ready for the stone cladding.

Part 2 of 3: Laying the Stone

1 Mix the mortar in the same proportion as for the first layer of plaster. Mix for at least 5 minutes, until you get the consistency of mashed potatoes. Too liquid solution loses strength. Too dry mortar sets very quickly.

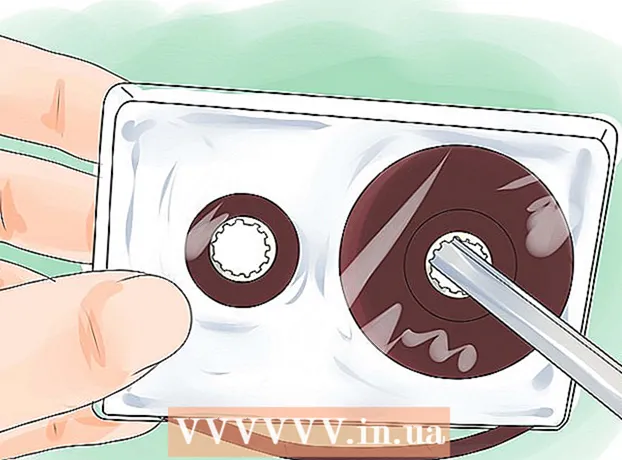

1 Mix the mortar in the same proportion as for the first layer of plaster. Mix for at least 5 minutes, until you get the consistency of mashed potatoes. Too liquid solution loses strength. Too dry mortar sets very quickly.  2 Determine the order in which the stones are laid. It will be useful to perform a test installation without mortar and determine the pattern on the wall. Spending a little time planning the placement of the stones will save you time on sizing later.

2 Determine the order in which the stones are laid. It will be useful to perform a test installation without mortar and determine the pattern on the wall. Spending a little time planning the placement of the stones will save you time on sizing later. - If that helps, test the installation on the floor, not on the wall. This will give you an idea of the general arrangement of the stones.

3 Use a chipper, trowel edge, or other blunt tool to shape the stones into the desired shape. It is very easy to give the stones the desired shape. Subsequently, you can hide the knocked-off edges with mortar, so do not try to give them the perfect shape.

3 Use a chipper, trowel edge, or other blunt tool to shape the stones into the desired shape. It is very easy to give the stones the desired shape. Subsequently, you can hide the knocked-off edges with mortar, so do not try to give them the perfect shape.  4 Thoroughly remove dirt, sand and other materials from stones. The mortar adheres best to a clean surface.

4 Thoroughly remove dirt, sand and other materials from stones. The mortar adheres best to a clean surface.  5 Dry the stones so that later it will be noticeable that the surface of the stones is wet. If necessary, wet the stones with a construction brush, but do not overdo it. Due to this, the stones will not absorb moisture from the solution, as a result of which the adhesion will be more durable.

5 Dry the stones so that later it will be noticeable that the surface of the stones is wet. If necessary, wet the stones with a construction brush, but do not overdo it. Due to this, the stones will not absorb moisture from the solution, as a result of which the adhesion will be more durable.  6 Apply the solution to the stones one at a time. The layer of the solution should be about 1.3 cm. If the solution accidentally falls on the front surface of the stone, then it must be wiped off with a damp cloth until it dries.

6 Apply the solution to the stones one at a time. The layer of the solution should be about 1.3 cm. If the solution accidentally falls on the front surface of the stone, then it must be wiped off with a damp cloth until it dries.  7 Start laying stones starting from the bottom corners. Cut edges should be directed up or down, away from the main focus. Scrolling a little, press the stones into the solution to squeeze out a little excess and make the bond stronger. To remove excess mortar that has protruded beyond the finished joint or onto the surface of the stone, use a trowel, jointing or brush.

7 Start laying stones starting from the bottom corners. Cut edges should be directed up or down, away from the main focus. Scrolling a little, press the stones into the solution to squeeze out a little excess and make the bond stronger. To remove excess mortar that has protruded beyond the finished joint or onto the surface of the stone, use a trowel, jointing or brush. - For best results, make sure the seams are the same. The length of the seams should be between 2.5 and 7.5 cm.

8 Continue applying mortar and laying stones until the entire wall is complete. Work intermittently; take a step back from time to time and carefully examine what you get. When cladding adjacent walls, you will also need corner stones. They are made by almost all manufacturers of facing stones, and the stones themselves give the facing a more natural look.

8 Continue applying mortar and laying stones until the entire wall is complete. Work intermittently; take a step back from time to time and carefully examine what you get. When cladding adjacent walls, you will also need corner stones. They are made by almost all manufacturers of facing stones, and the stones themselves give the facing a more natural look.

Part 3 of 3: Final finishing

1 After all the stones have been laid, fill the joints with mortar. It is best to use a special joint mortar. At this point, you can hide all the cut faces. With the help of a special tool, obtain the required depth of the joints during the hardening of the mortar.

1 After all the stones have been laid, fill the joints with mortar. It is best to use a special joint mortar. At this point, you can hide all the cut faces. With the help of a special tool, obtain the required depth of the joints during the hardening of the mortar.  2 Remove any excess from the surface with clean water and a brush. Remove the mortar from the front faces of the facing stones within half an hour - after 24 hours, the solution cannot be removed at all.

2 Remove any excess from the surface with clean water and a brush. Remove the mortar from the front faces of the facing stones within half an hour - after 24 hours, the solution cannot be removed at all. - Clean the filled joints with a paint brush until the mortar is completely solidified. Pay special attention to this when cladding the walls in the room, as they should look as neat as possible.

3 Apply sealant according to the manufacturer's directions. Treated stones are easier to clean and maintain, and some sealants provide stain protection. Reapply sealant periodically for maximum effect. Note that some sealants discolor the stone or create a “wet” glossy effect.

3 Apply sealant according to the manufacturer's directions. Treated stones are easier to clean and maintain, and some sealants provide stain protection. Reapply sealant periodically for maximum effect. Note that some sealants discolor the stone or create a “wet” glossy effect.

Tips

- Stagger the stones to avoid continuous grout lines.

- When applying stone sealant, be aware that some of them can discolor the stone or make the surface shiny, so always apply the sealant to the test stone first.

- Take a few steps back from time to time and inspect your work to properly alternate stones of different colors and sizes.

Warnings

- For exterior walls: Perform stone cladding in dry weather at temperatures above 5 degrees.

- For exterior walls: properly waterproof to prevent excessive water ingress