Author:

Mark Sanchez

Date Of Creation:

28 January 2021

Update Date:

1 July 2024

Content

Our world is being built by the hands of welders (although not only). From construction to racing car manufacturing to industry, welders are needed everywhere to weld metal. If you want to become a welder, then you need to undergo appropriate training and practice, as well as obtain the appropriate certificates. All this and more - this article.

Steps

Part 1 of 3: Training

1 Find out more about what is required of the welder. And what is required of them is good health (physical and mental), excellent hand-eye coordination and the ability to focus all their attention on something for a long time. Awkwardness and carelessness are not the qualities expected from a welder. Welders take great pride in their work and the skills that enable them to do it flawlessly.

1 Find out more about what is required of the welder. And what is required of them is good health (physical and mental), excellent hand-eye coordination and the ability to focus all their attention on something for a long time. Awkwardness and carelessness are not the qualities expected from a welder. Welders take great pride in their work and the skills that enable them to do it flawlessly. - A good welder must be able to motivate himself, which is understandable - the work of a welder assumes that you will have to look for orders on your own (maybe not always, but still). The demand for welders may be high, but it will be up to you whether your skills are suitable for the customers.

- A welder works near hot metal, bright lights and toxic fumes on a daily basis. He also has very heavy equipment, which, by the way, is very traumatic. Accordingly, before enrolling in welding courses, you should carefully weigh the pros and cons.

2 Look for welding courses and other training programs. If you, as they say, did not hold welding in your hands, then the courses will be your first step into the profession. Actually, such courses can be found in the curriculum of many vocational schools and other similar educational institutions. And, objectively speaking, talented welders come out of the walls of many such educational institutions, whose skills can be very, very popular.

2 Look for welding courses and other training programs. If you, as they say, did not hold welding in your hands, then the courses will be your first step into the profession. Actually, such courses can be found in the curriculum of many vocational schools and other similar educational institutions. And, objectively speaking, talented welders come out of the walls of many such educational institutions, whose skills can be very, very popular. - In the United States, for example, there are three of the best educational institutions that produce welders: Tulsa Welding School, Hobart Institute of Welding Technology, Lincoln Welding School.

- Again, in the United States, you can even receive a scholarship while studying, both from an educational institution and from various enterprises (details are here). However, this is understandable - there are few good welders, there is a demand for them, so it makes sense to spend money on personnel training.

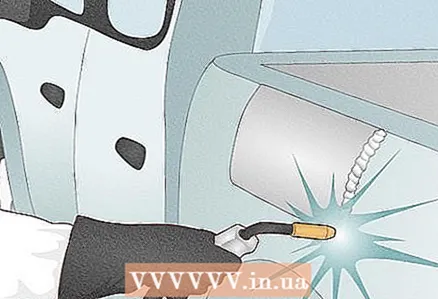

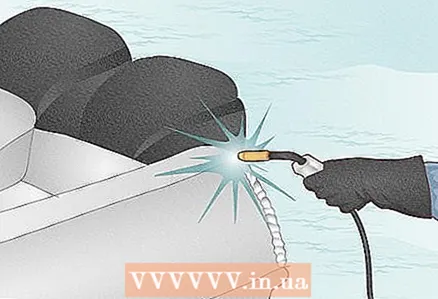

3 Start cooking metal. You will not be able to learn this from books, because this is a craft (sometimes, of course, an art), which can only be mastered through practice. Where you will practice is another matter, the point is for you to practice.

3 Start cooking metal. You will not be able to learn this from books, because this is a craft (sometimes, of course, an art), which can only be mastered through practice. Where you will practice is another matter, the point is for you to practice. - Courses at a vocational school will help you if you do not have any experience in working with welding (or have, but just a little). There you will be taught how to work safely with welding, and will also tell you about the basic techniques for welding metal. Then you can start practicing on your own.

- Learn to work with the welding arc, tack weld, and control the melt. Since you have to start somewhere, the first step is to learn how to make small seams - the so-called "tack welds" to weld pieces of metal together. At the same stage, you must learn how to handle the welding machine. It will take time, you will need the help of an experienced welder, but will that stop you?

- Nowadays, metal welding is often carried out using the tubular electrode welding method, which is understandable - this way the work is done faster and better. However, keep in mind: study follows what you plan to make money with.

4 Consider which welding method is best for a particular job. Welders boil, boil, boil - but everywhere have their own characteristics. Accordingly, if you plan to work in a particular industry, then you should immediately begin to go to the appropriate specialization:

4 Consider which welding method is best for a particular job. Welders boil, boil, boil - but everywhere have their own characteristics. Accordingly, if you plan to work in a particular industry, then you should immediately begin to go to the appropriate specialization: - The inert gas consumable arc welding is used for steel, stainless steel and aluminum, especially in the automotive and shipbuilding industries.

- Consumable arc welding, in turn, is an easier and more popular welding method, often used in construction and various types of home projects.

- TIG manual metal arc welding is a slow process that requires pure metal.On the other hand, slowly - yes, very high quality. This type of welding is used for the production of stainless steel architectural objects. In addition, this type of welding is, one might say, the pinnacle of skill, welders who know how to cook metal in such a way - for grabbing.

- However, there are other types of welding, albeit less popular. Here you can remember about gas-electric tungsten welding, which is used for the production of bicycles and airplanes.

5 Take part in a so-called mentoring program. Actually, such programs are conducted under the patronage of different companies, where they will teach you basic welding techniques (and, perhaps, not only them). With enough hours of this program, you will be ready to move to the next level.

5 Take part in a so-called mentoring program. Actually, such programs are conducted under the patronage of different companies, where they will teach you basic welding techniques (and, perhaps, not only them). With enough hours of this program, you will be ready to move to the next level. - It may take about three years to grow to the stage of "skilled welder", although not a fact - you can handle it both earlier and later.

- There may be no such programs in your country, but this does not mean that various practices and internships will not help you find a job and acquire the necessary skills.

- Best of all, of course, are those programs that promise further employment, or at least help in the further job search. It is best if such a program also involves meeting with potential employers.

Part 2 of 3: Certification

1 People skilled in metal welding can occupy different positions. As with any job, there is a difference between what you will expect from a novice welder and what you will expect from a more experienced welder. The experience and certifications required for a particular job may differ, sometimes even more than significantly.

1 People skilled in metal welding can occupy different positions. As with any job, there is a difference between what you will expect from a novice welder and what you will expect from a more experienced welder. The experience and certifications required for a particular job may differ, sometimes even more than significantly. - Welders they do only one thing - they cook metal. A good welder can be snapped up, such a specialist can be invited to several enterprises at once. Remember: the welder solves only one problem (weld two pieces of metal to each other), everything else is beyond his competence. Nevertheless, representatives of other professions can participate in the welding process willy-nilly.

- Welding engineers, in turn, these are already specialists of broader competence. Thus, they can solve organizational and managerial issues related to projects in which welding works are carried out. It will not be superfluous for welding engineers to know CAD, as well as have a diploma in the relevant specialty.

- Instructors - these are certified specialists, whose qualifications are confirmed by various diplomas, they are ways to teach other people the intricacies of welding. If you yourself want to try yourself in this field, then you should know that there is work here. True, it will take a long time and a lot to learn ...

- Receivers of welded products - these are those who assess the quality of the welder's work in terms of compliance with industry quality standards. Experience, seniority, straight arms - that's what is required to work in this position.

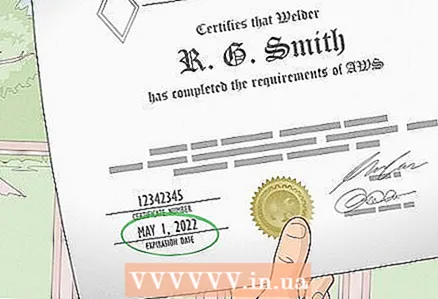

2 Receive a diploma or certificate confirming your competence. You may have to take exams with a certain regularity in order to confirm your qualifications. However, consider it as a necessity.

2 Receive a diploma or certificate confirming your competence. You may have to take exams with a certain regularity in order to confirm your qualifications. However, consider it as a necessity. - What kind of certificate or diploma you need will depend on where you are and what you plan to try your hand at.

- For example, US welding engineers must complete the Welding Engineer AWS Certification, which will test their knowledge of a variety of topics and disciplines related to welding. Upon completion of this verification, welding engineers become Certified Welding Engineers (CWE).

- Sometimes there is an opportunity to get a job as a welder without a diploma. However, unless you have a huge and rich experience, it will not be easy for you to compete with those who have diplomas. However, getting a diploma, at least some, is not so difficult.

3 Master skills that complement the welder's job. For example, learn to read blueprints, lead a team, control the progress of a project, and so on - in general, become a truly "versatile" specialist, so it will be easier for you to look for a job. Here you will be helped by both courses, there and independent study, and the help of friends and colleagues.

3 Master skills that complement the welder's job. For example, learn to read blueprints, lead a team, control the progress of a project, and so on - in general, become a truly "versatile" specialist, so it will be easier for you to look for a job. Here you will be helped by both courses, there and independent study, and the help of friends and colleagues. - Even if you, working as a welder, do not feel the need to master this or that welding technique (or another skill), keep in mind this: the better you are at welding, the easier it is to look for a job.

Part 3 of 3: Finding a Job

1 Send your resume to different businesses. Welders are needed in many places, even if the vacancies for which you will respond will differ depending on your skills and experience. By the way, don't forget to use online job exchanges.

1 Send your resume to different businesses. Welders are needed in many places, even if the vacancies for which you will respond will differ depending on your skills and experience. By the way, don't forget to use online job exchanges. - A resume, diploma and medical book - that's probably all that is needed in most cases.

2 Do not lag behind! Reaffirm your qualifications and improve them regularly. Trust me, it will affect your salary!

2 Do not lag behind! Reaffirm your qualifications and improve them regularly. Trust me, it will affect your salary! - If you are lucky enough to find a full-time job, then you may need to regularly take refresher courses and all that jazz. However, it will only benefit you.

- To become the best candidate for any vacancy, it is important to constantly improve your qualifications and competencies. There is no limit to perfection!

3 Specialize. If you feel that your soul lies in a particular type of welding business, then do not deny yourself the pleasure of learning a new aspect of the profession. The more you can do it, the easier it is for you to find a job.

3 Specialize. If you feel that your soul lies in a particular type of welding business, then do not deny yourself the pleasure of learning a new aspect of the profession. The more you can do it, the easier it is for you to find a job. - Most often, welding lights are lit in shipyards, factories, construction sites and various pipelines - but everywhere, to be sure, there can be subtleties and peculiarities. If you are interested in this or that direction, but you are not very clear about the requirements for welders there, then look for the relevant information.

4 Work, if possible, on different objects. When you have 10-20 years of experience behind you, you are unlikely to have problems finding a good job. The more you weld metal on your way as a welder, the more opportunities you have, the easier it is for you to learn new things and the higher your salary.

4 Work, if possible, on different objects. When you have 10-20 years of experience behind you, you are unlikely to have problems finding a good job. The more you weld metal on your way as a welder, the more opportunities you have, the easier it is for you to learn new things and the higher your salary. - Apply for jobs that involve business trips or even relocation. If you haven't found a job nearby, why not go somewhere else? Many welders have chosen such a life for themselves. In the end, the rotational method is not so bad.

Tips

- Look for on-the-job training programs that may include employer-sponsored courses.

- Look for on-the-job training programs that may include employer-sponsored courses.

Warnings

- Being a welder means working with sophisticated equipment and appliances that use high temperatures, emit dazzling light and generate potentially harmful fumes. Depending on the industry, training, welding method and tools used, the job of a welder can be hazardous if the proper safety equipment is not used correctly.