Author:

William Ramirez

Date Of Creation:

20 September 2021

Update Date:

1 July 2024

Content

- Steps

- Method 1 of 3: Bending a steel pipe with a pipe bending machine

- Method 2 of 3: Bending a Steel Pipe with a Blow Torch

- Method 3 of 3: Tube Bending

- Tips

- Warnings

- What do you need

Bending of steel pipes may be required for various purposes. Depending on the size of the pipe and the type of bend, there are different methods of bending it.

Steps

Method 1 of 3: Bending a steel pipe with a pipe bending machine

1 Get a pipe bending machine. There are many different tube bending machines sold in hardware stores at different prices. Their main difference lies in the amount of hydraulic force applied to the pipe, as well as in the strength of the dies.

1 Get a pipe bending machine. There are many different tube bending machines sold in hardware stores at different prices. Their main difference lies in the amount of hydraulic force applied to the pipe, as well as in the strength of the dies. - Dies are curved shapes into which a bendable pipe is inserted. Different dies correspond to different pipe diameters. In addition, there are punches for round and rectangular pipes.

- Be careful to get a pipe bending machine with a fixed outer diameter, not an inner diameter. These machines are not identical and have different dies. Using the wrong machine can flatten, buckle and twist the bent pipe.

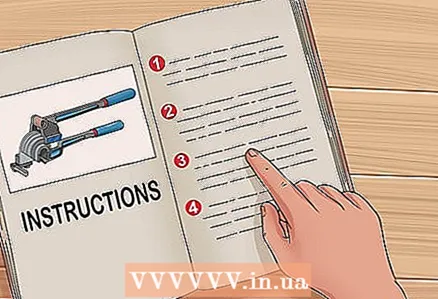

2 Follow the instructions. Typically, specific equipment has specific features. Carefully study the instructions supplied with the machine.

2 Follow the instructions. Typically, specific equipment has specific features. Carefully study the instructions supplied with the machine.  3 Select a stamp of the appropriate size. For example, if you want to bend a 2 cm diameter pipe, use a die of the same size.

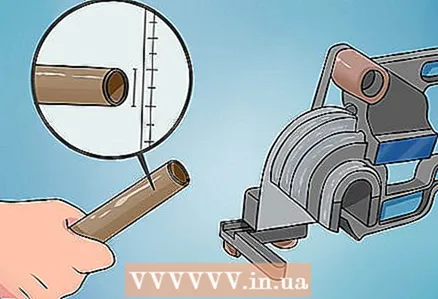

3 Select a stamp of the appropriate size. For example, if you want to bend a 2 cm diameter pipe, use a die of the same size. - Using the correct stamp is extremely important. If the pipe does not fit snugly against the die, it may flatten and warp when bent.

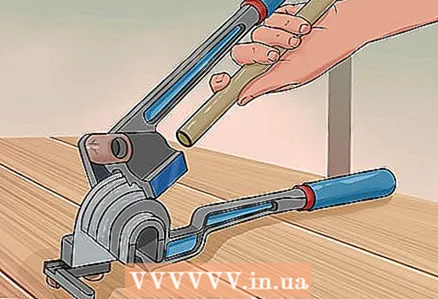

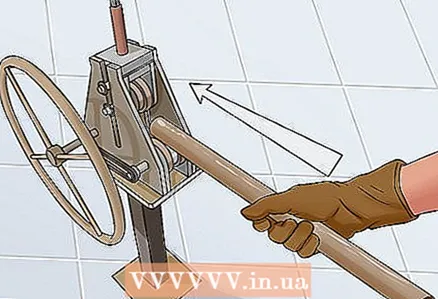

4 Insert the pipe into the machine. Having installed the stamp, place the pipe in it so that the place of the future bend is in the middle of the stamp. Then clamp the pipe firmly with the pneumatic lever.

4 Insert the pipe into the machine. Having installed the stamp, place the pipe in it so that the place of the future bend is in the middle of the stamp. Then clamp the pipe firmly with the pneumatic lever.  5 Measure the required bend angle. It is impossible to set the angle you need on a pipe bending machine, so it must be additionally controlled.

5 Measure the required bend angle. It is impossible to set the angle you need on a pipe bending machine, so it must be additionally controlled. - The simplest solution is to use a digital protractor that can be attached to the pipe before bending it. In the process of bending the pipe, you will be able to observe the angle of its bending.

6 Bend the pipe to the required angle. The higher the force applied to the machine, the sharper the angle the pipe will bend. As soon as the goniometer fixes the angle you need, release the pressure on the pipe and remove it from the machine.

6 Bend the pipe to the required angle. The higher the force applied to the machine, the sharper the angle the pipe will bend. As soon as the goniometer fixes the angle you need, release the pressure on the pipe and remove it from the machine.  7 Practice on unnecessary pipes. Since too much pressure can cause the pipe to buckle, practice on unnecessary pipes before bending the pipe you need.

7 Practice on unnecessary pipes. Since too much pressure can cause the pipe to buckle, practice on unnecessary pipes before bending the pipe you need. - Before placing the pipe in the machine, fill it with sand to prevent it from buckling and twisting.

Method 2 of 3: Bending a Steel Pipe with a Blow Torch

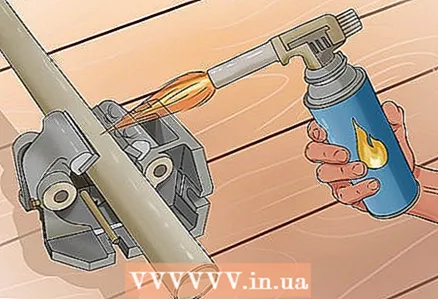

1 Get a blowtorch. If you don't have one, buy an acetylene burner that delivers constant heat.

1 Get a blowtorch. If you don't have one, buy an acetylene burner that delivers constant heat.  2 Clamp the pipe in a vise. Tighten the vise, clamping the pipe tightly; however, do not use too much force to flatten the pipe.

2 Clamp the pipe in a vise. Tighten the vise, clamping the pipe tightly; however, do not use too much force to flatten the pipe. - Some vices are supplied with special grips for cylindrical pipes. However, you can do without such grips.

3 Heat the pipe in the place of the future bend. Use an acetylene torch to heat the place where you are going to bend the pipe. Heat the pipe around the entire diameter (perimeter), not just one side. At high temperatures, the metal has increased ductility, which will avoid warping and uneven deformation of the pipe.

3 Heat the pipe in the place of the future bend. Use an acetylene torch to heat the place where you are going to bend the pipe. Heat the pipe around the entire diameter (perimeter), not just one side. At high temperatures, the metal has increased ductility, which will avoid warping and uneven deformation of the pipe.  4 Bend the pipe smoothly and evenly. Don't try to jerkily. Act smoothly, gradually increasing the pressure.

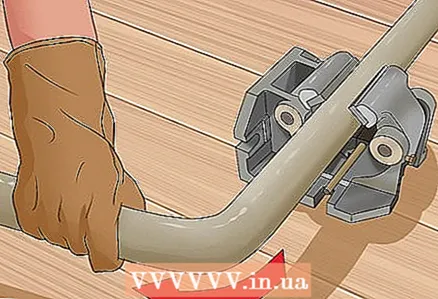

4 Bend the pipe smoothly and evenly. Don't try to jerkily. Act smoothly, gradually increasing the pressure. - You can use a wrench or a larger diameter pipe by sliding it over the bent pipe, or simply bend it by hand. Note, however, that the pipe will be hot, so wear heavy fireproof gloves.

- At this stage, you may need help: one person will bend the pipe and the other will warm it up.

- Filling the pipe with some kind of non-combustible material such as sand will prevent it from flattening and buckling.

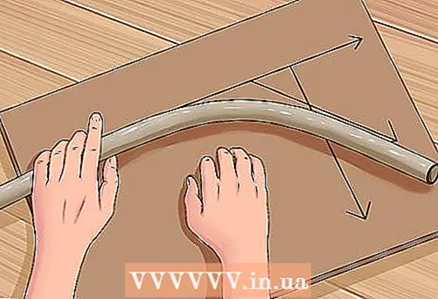

5 Bend the pipe to the required angle. One of the simplest ways to measure the bend angle is to prepare a template from a different material; such a template can, for example, be cut from plywood or thick cardboard. Place the template on the pipe and move the burner away from the pipe.

5 Bend the pipe to the required angle. One of the simplest ways to measure the bend angle is to prepare a template from a different material; such a template can, for example, be cut from plywood or thick cardboard. Place the template on the pipe and move the burner away from the pipe.

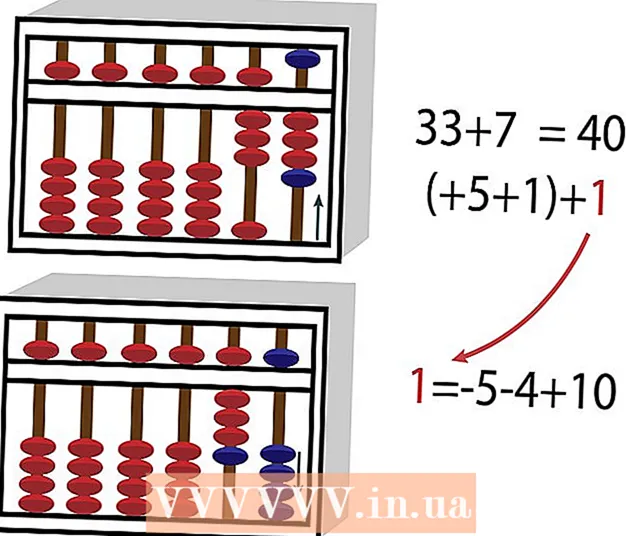

Method 3 of 3: Tube Bending

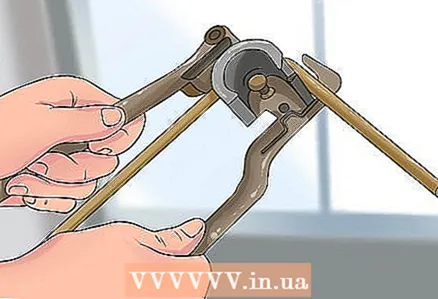

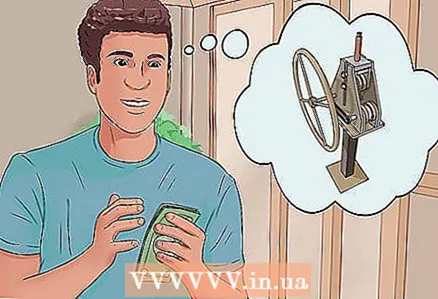

1 Get a tube rolling machine. If you need to bend a whole set of pipes to a specific angle, this machine will greatly facilitate your task. You can buy a tube rolling machine at a hardware supermarket for less than pneumatic tube bending machines.

1 Get a tube rolling machine. If you need to bend a whole set of pipes to a specific angle, this machine will greatly facilitate your task. You can buy a tube rolling machine at a hardware supermarket for less than pneumatic tube bending machines. - As with tube benders, various dies are attached to a tube mill, and bending a pipe of a certain diameter requires choosing the correct die to avoid flattening it.

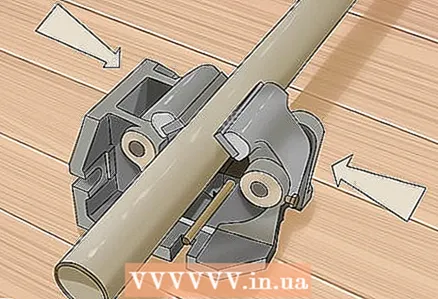

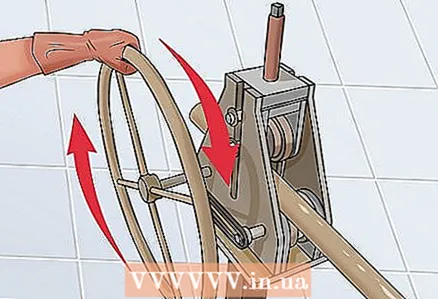

2 Place the pipe on the machine. The principle of operation of a pipe rolling machine is to apply an ever-increasing force to the pipe as it moves back and forth. Having installed the appropriate stamp in the machine, insert the pipe into it.

2 Place the pipe on the machine. The principle of operation of a pipe rolling machine is to apply an ever-increasing force to the pipe as it moves back and forth. Having installed the appropriate stamp in the machine, insert the pipe into it. - When working on a pipe rolling machine, the pipe is inserted from one end.

3 Clamp the vise tightly around the pipe. Most machines have a hex screw that can be tightened using a standard wrench.

3 Clamp the vise tightly around the pipe. Most machines have a hex screw that can be tightened using a standard wrench.  4 Feed the pipe into the machine. Most tube rolling mills are equipped with a large wheel that rotates when the tube is rolled.

4 Feed the pipe into the machine. Most tube rolling mills are equipped with a large wheel that rotates when the tube is rolled. - Spinning the wheel will require some effort, especially in the final stages of rolling.

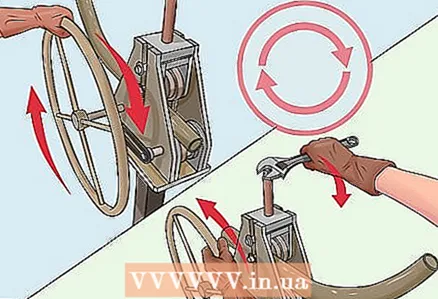

5 Increase the pressure on the pipe. After passing the tube through the rolling machine once, reduce the roll spacing by turning the clamp about a quarter turn.

5 Increase the pressure on the pipe. After passing the tube through the rolling machine once, reduce the roll spacing by turning the clamp about a quarter turn.  6 Pass the pipe in the opposite direction. The machine wheel can be turned in the opposite direction so that you can pass the pipe from the other side.

6 Pass the pipe in the opposite direction. The machine wheel can be turned in the opposite direction so that you can pass the pipe from the other side.  7 Repeat until you bend the pipe to the desired angle. Continue to decrease the roll spacing by turning the clamp about a quarter of a full turn each time. After a few passes, you will notice how the pipe begins to bend. Continue rolling the pipe until you get the shape you want.

7 Repeat until you bend the pipe to the desired angle. Continue to decrease the roll spacing by turning the clamp about a quarter of a full turn each time. After a few passes, you will notice how the pipe begins to bend. Continue rolling the pipe until you get the shape you want. - If you have an angle template, apply it to the pipe after each pass.

Tips

- If you only need to bend a few pipes, and you do not intend to do this in the future, it will be cheaper to take the pipes to the nearest workshop.

- Practice on unnecessary pipes before starting work.

- The flame of a gas burner "stains" the steel, so be prepared to descale.

- Remember that metal can become more brittle after heating.

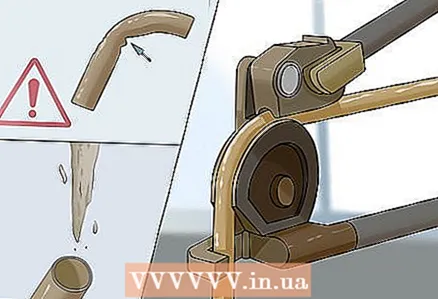

Warnings

- Read the instructions supplied with the equipment carefully, paying particular attention to safety precautions.

- Hydraulic pipe bending machines use high pressures that can cause the pipe to break and fly apart. Therefore, increase the pressure gradually.

- Take extra care when using a blowtorch: wear fireproof gloves and have a fire extinguisher nearby.

What do you need

- Safety glasses when using a gas burner.

- Fireproof gloves.

- Blow torch bending vise

- Acetylene torch for blowtorch bending method

- Hydraulic machine for the first method

- Sand for bending by hydraulic machine

- Plan or scheme

- Steel pipe (available at a hardware store)

- Tube rolling machine for the third method

- Wrench