Author:

Alice Brown

Date Of Creation:

24 May 2021

Update Date:

1 July 2024

Content

- Steps

- Method 1 of 3: Removing a blockage from the washer nozzles

- Method 2 of 3: Soaking or replacing the nozzles

- Method 3 of 3: Inspecting and Repairing the Washer Tubes

Clogged windscreen washer nozzles are a common problem. Typically, the source is automotive wax or varnish, which creates a blockage in the top of the nozzle, preventing the liquid from spraying onto the windshield. Despite all the inconveniences, this problem is easy enough to fix. If it is not possible to clear the blockage, there is also nothing difficult in replacing the nozzle.

Steps

Method 1 of 3: Removing a blockage from the washer nozzles

1 Listen to the washer pump. Before you start cleaning the nozzles, turn them on and listen to the low hum of the windscreen washer pump. If the nozzles are clogged, you will still hear the pump running despite not spraying.

1 Listen to the washer pump. Before you start cleaning the nozzles, turn them on and listen to the low hum of the windscreen washer pump. If the nozzles are clogged, you will still hear the pump running despite not spraying. - If you are not sure if the pump is on, ask a friend to stand near the hood and listen to it from outside the car.

- If the pump is not audible, it must be replaced.

2 Inspect the nozzles for external blockages. Locate the nozzles at the top of the bonnet, near the windshield, and investigate the cause of the blockage. Often, car wax or varnish can clog the nozzles of the nozzles, thereby preventing the fluid from being sprayed correctly.

2 Inspect the nozzles for external blockages. Locate the nozzles at the top of the bonnet, near the windshield, and investigate the cause of the blockage. Often, car wax or varnish can clog the nozzles of the nozzles, thereby preventing the fluid from being sprayed correctly. - Wipe off any wax or varnish that is interfering with the nozzles.

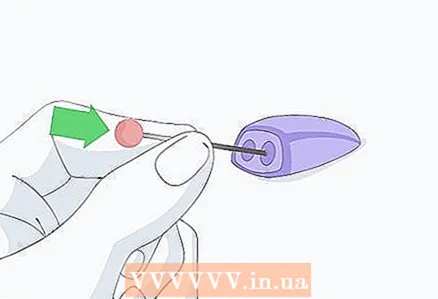

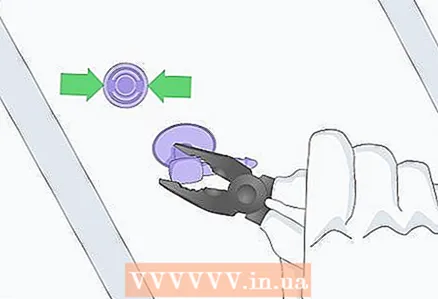

3 Use a pin to clear a deep blockage. If clearing the blockage does not clear the nozzle sufficiently to spray the windshield washer, try unclogging the nozzles with a pin or needle. Push a pin into all holes of the nozzle, after each time cleaning it from the removed dirt.

3 Use a pin to clear a deep blockage. If clearing the blockage does not clear the nozzle sufficiently to spray the windshield washer, try unclogging the nozzles with a pin or needle. Push a pin into all holes of the nozzle, after each time cleaning it from the removed dirt. - Do not insert the pin too deep, otherwise you will not be able to pull it out.

- Do not push the needle too hard into the back of the nozzle or inadvertently breaking it or the nozzle.

4 Feed the wire through the nozzle. If the pin is too short to clear the blockage in the injector, go under the hood and disconnect the hose at the bottom of the injector. Then pull the thin wire through the bottom of the nozzle up to the nozzle. If the nozzle has multiple holes, pull the wire several times until both holes are clear.

4 Feed the wire through the nozzle. If the pin is too short to clear the blockage in the injector, go under the hood and disconnect the hose at the bottom of the injector. Then pull the thin wire through the bottom of the nozzle up to the nozzle. If the nozzle has multiple holes, pull the wire several times until both holes are clear. - Guitar strings are ideal for this task as they are stiff enough to fit through the nozzle.

- You can also use stripped electrical wire.

Method 2 of 3: Soaking or replacing the nozzles

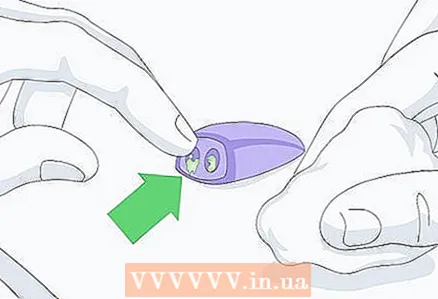

1 Disconnect the hose from the bottom of the nozzle. The rubber hose at the bottom of the nozzle is held in place solely by the pressure it exerts on the nozzle, so it should be removed with relative ease.

1 Disconnect the hose from the bottom of the nozzle. The rubber hose at the bottom of the nozzle is held in place solely by the pressure it exerts on the nozzle, so it should be removed with relative ease. - Squeeze the hose with your index finger and thumb in the area of the nozzle and pull it towards you to remove.

- If the hose gets stuck, grab a pair of pliers and twist it back and forth to release it.

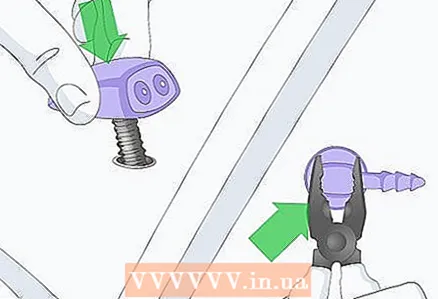

2 Use pliers to pull the nozzle out of the hood. The windscreen washer nozzles are secured with plastic latches. Take a pair of pliers and press the latches into the nozzle and then pull them up.

2 Use pliers to pull the nozzle out of the hood. The windscreen washer nozzles are secured with plastic latches. Take a pair of pliers and press the latches into the nozzle and then pull them up. - When the latch is pressed, the injector should be easily pulled out of the hole in the hood.

- Do not be afraid to break the valves if you decide to completely replace the nozzles. Otherwise, try not to damage them.

3 Remove the injectors from the hood. Lower the bonnet again and pull the injector upwards, pulling it out of the hole. If you have already taken care of the valves, then the nozzle should pop out of the hole without any resistance.

3 Remove the injectors from the hood. Lower the bonnet again and pull the injector upwards, pulling it out of the hole. If you have already taken care of the valves, then the nozzle should pop out of the hole without any resistance. - If the injector gets stuck somewhere, open the hood and squeeze the clips with pliers to disconnect them again.

- Be careful not to damage the paint on the hood while pulling out the nozzles.

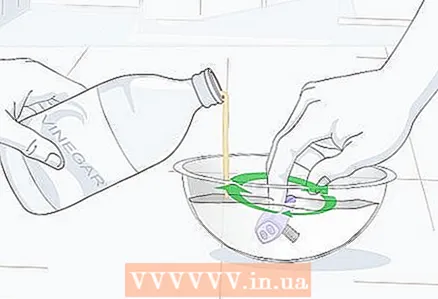

4 Soak the nozzles in a bowl of vinegar. You may be able to get rid of the blockages in the nozzles by soaking them in a bowl of vinegar for a while. Move the nozzles a little in the vinegar so that it will certainly penetrate the blockages. After a few minutes, remove the nozzles from the vinegar and rinse them.

4 Soak the nozzles in a bowl of vinegar. You may be able to get rid of the blockages in the nozzles by soaking them in a bowl of vinegar for a while. Move the nozzles a little in the vinegar so that it will certainly penetrate the blockages. After a few minutes, remove the nozzles from the vinegar and rinse them. - Try blowing into the nozzle after rinsing to see if the blockage has cleared.

- If the injector is clean, return it to the vehicle.

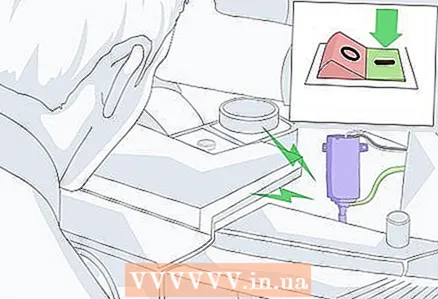

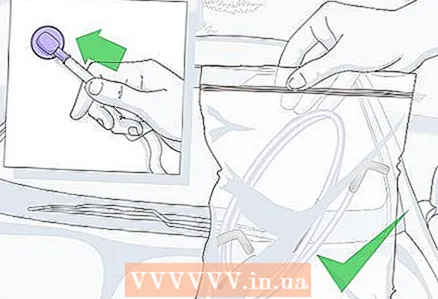

5 Install new washer nozzles. It doesn't matter if you buy new washer nozzles or return cleaned ones, the installation process remains the same. Insert the nozzle through the hole in the top of the bonnet so that the nozzles point towards the windshield. When they are at the very bottom, the plastic clips will spread apart and hold the nozzles in place.

5 Install new washer nozzles. It doesn't matter if you buy new washer nozzles or return cleaned ones, the installation process remains the same. Insert the nozzle through the hole in the top of the bonnet so that the nozzles point towards the windshield. When they are at the very bottom, the plastic clips will spread apart and hold the nozzles in place. - Once the nozzle is in place, connect the washer to it.

- Start the engine and turn on the new injectors to make sure they are working correctly.

Method 3 of 3: Inspecting and Repairing the Washer Tubes

1 Examine the tubes from the washer fluid reservoir. If the washer nozzles do not spray the washer fluid onto the windshield, the problem may lie in a break or kink in the hose from the washer fluid reservoir to the nozzle. Inspect tubing for blockages or damage.

1 Examine the tubes from the washer fluid reservoir. If the washer nozzles do not spray the washer fluid onto the windshield, the problem may lie in a break or kink in the hose from the washer fluid reservoir to the nozzle. Inspect tubing for blockages or damage. - Start at the reservoir and follow the tubes all the way to the nozzles that are attached to the hood.

- Look for signs of leaks, kinks, and other possible damage.

2 Clean the blockage in the hoses with an air compressor. If the hoses appear to be in good working order, there may be a blockage in one of the hoses. Pull the hose out of the nozzle on the nozzle and the nozzle on the reservoir, and then blow the tube out with an air compressor or can of compressed air to clear the blockage.

2 Clean the blockage in the hoses with an air compressor. If the hoses appear to be in good working order, there may be a blockage in one of the hoses. Pull the hose out of the nozzle on the nozzle and the nozzle on the reservoir, and then blow the tube out with an air compressor or can of compressed air to clear the blockage. - If air does not pass through the tube, it will need to be replaced.

- If air flows freely through the tube, replace it.

3 Replace damaged washer fluid hoses. If you are unable to clear the blockage in the hose, it will need to be replaced. Purchase a new hose from your local auto parts store, or take your clogged hose with you and replace it with a rubber hose of the same diameter. The length of the new hose must match the length of the old one.

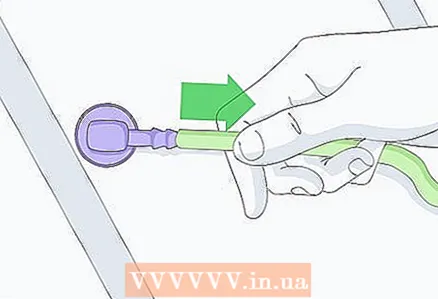

3 Replace damaged washer fluid hoses. If you are unable to clear the blockage in the hose, it will need to be replaced. Purchase a new hose from your local auto parts store, or take your clogged hose with you and replace it with a rubber hose of the same diameter. The length of the new hose must match the length of the old one. - Attach the new hose to the same nozzles from which you removed the old one.

- After replacing the hose, check the operation of the injectors again.