Content

So, your teacher decided to run a race among cars made from a mousetrap. Do you want to win? Thanks to these instructions, you will learn how to make such a machine, and also adjust it so that it will travel the maximum distance in the minimum time. How to get the farthest? It is necessary to reduce weight, reduce friction in the axle of the wheels, use a longer lever. The typewriter should be narrow and long. The axle itself should be small in diameter, and the rear wheels should be large. Every time the axle turns, the wheels turn, which means that with larger wheels the car will go further. The long arm tip works like this: the spring is tightened more slowly, which means the energy is consumed more slowly. Although this makes the car travel at a low speed, it will travel more because the traction force is used more efficiently. While the materials used will be different from the rest, there are a few things to pay attention to. First, the spring force is limited. Friction and traction should also be taken into account. It is necessary to use our "mechanical innovations", to minimize the mass, then our machine will travel a greater distance.

Steps

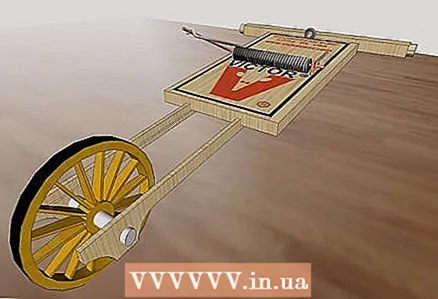

1 Build a lightweight car frame. Attach a mousetrap and wheels to it. Look at the picture - the frame may be smaller than the mousetrap. Don't forget to trim the frame - the lighter it gets, the better! Keep in mind that it still needs to be sturdy - for example, a wood frame will be stronger than a foam frame.

1 Build a lightweight car frame. Attach a mousetrap and wheels to it. Look at the picture - the frame may be smaller than the mousetrap. Don't forget to trim the frame - the lighter it gets, the better! Keep in mind that it still needs to be sturdy - for example, a wood frame will be stronger than a foam frame.  2 Make sure that the spring is directed correctly - the mousetrap lever should jerk forward when starting. The mousetrap itself must not touch the front wheels. The greater the distance between it and the wheels, the better (relatively).

2 Make sure that the spring is directed correctly - the mousetrap lever should jerk forward when starting. The mousetrap itself must not touch the front wheels. The greater the distance between it and the wheels, the better (relatively).  3 The main part of your car will be the rear wheels. The front ones, in turn, will not affect anything much, no matter how large or how many there are. You can even use only one. But as for the rear wheels, they should be as large as possible. The axis between them should be thin. For example, you can take a couple of CDs, and to reduce the hole in them, you can insert a regular water washer.

3 The main part of your car will be the rear wheels. The front ones, in turn, will not affect anything much, no matter how large or how many there are. You can even use only one. But as for the rear wheels, they should be as large as possible. The axis between them should be thin. For example, you can take a couple of CDs, and to reduce the hole in them, you can insert a regular water washer.  4 For better grip, wrap the wheels with duct tape, rubber band, or a regular balloon. If the wheels slide, energy will be wasted. The rear axle can also be pasted over for better traction.

4 For better grip, wrap the wheels with duct tape, rubber band, or a regular balloon. If the wheels slide, energy will be wasted. The rear axle can also be pasted over for better traction.  5 Use glue to attach the mousetrap to the frame, not bolts. The machine will normally hold on to the glue, but the bolts will add weight to it. The main thing is to make sure that all parts are correctly positioned before gluing. The bolts can be unscrewed, but you need to be careful with the glue.

5 Use glue to attach the mousetrap to the frame, not bolts. The machine will normally hold on to the glue, but the bolts will add weight to it. The main thing is to make sure that all parts are correctly positioned before gluing. The bolts can be unscrewed, but you need to be careful with the glue.

Tips

- The larger the mousetrap lever, the better. The car will travel more because the rear axle will rotate more. For example, you can use an antenna from a broken tape recorder. In general, anything that is long, lightweight and not very flexible will do.

* If the spring gets tangled in the axle, the car will not move at all. There must be a driving moment in the axis. For example, in the pictures you can see that we used a water washer - it acted like a gear and reduced the slip of the wheel axle.

- Soften the leverage with a cheese-like sponge. When the lever hits it, the machine will not bounce.

- Reduce friction on the axle by decreasing its contact surface. Using a piece of steel is more profitable than drilling a hole in a block of wood.

* Axle and foot alignment is essential to reduce friction and improve productivity.

- You also need to lubricate the wheels, axles, spring.

- The spring can be waxed to help it pull the wheel axle better.

- Take the disc with you when you go to get the washer. So you will definitely not go wrong with its size.

You can watch the students' cars on this Mouse Trap Car Challenge website.

- Grip needs to be increased with a rubber band or tape. Pay attention to the axle - it should turn the wheels, and not slip.

- Reduce weight with lightweight parts. Reducing the mass also reduces friction in the axle.

For consideration

- Wheel-to-axle ratio : Use large wheels and a thin axle to drive the car further. Think of a bicycle - the front sprockets are smaller than the rear sprockets.

- Inertia: How much energy does it take to make the car go? The lighter the machine, the less energy. Reduce the weight of the car so that it can go further.

*Launch speed: If you start slowly, then the power will be spent more efficiently, which means the machine will travel more. A long lever is needed to slow down the launch speed. The longer the lever, the more correctly the spring will tension. The car will go further, albeit at a slower pace.

- Friction: To minimize friction, the axle must be attached to the machine with a minimum contact area. For example, we used a narrow steel tube. Initially, we used a hole in the tree to fix it. Then I had to abandon this idea, because it caused friction, because of which the machine traveled a shorter distance.

- Traction force: This is what we call friction that works for us. Friction should be great where it is needed, namely when the axle turns the wheels and the wheels roll on the floor. If something slips in these places, energy will be wasted.

Warnings

- Mousetraps can be dangerous! You might break your finger. Do everything only under the supervision of adults, because you can get injured or break the mousetrap.

- Be careful when working with tools. When needed (for example, when cutting wood or working with hazardous materials), ask an adult for help.

- In a car, the amount of energy is limited by one thing - the force of the spring. Our machine is designed almost perfectly. If the lever or rear wheels were larger, the car would simply not go. In this case, it would be necessary to adjust the length of the lever (in our case, just shorten the antenna a little).