Author:

Louise Ward

Date Of Creation:

5 February 2021

Update Date:

28 June 2024

Content

Essential oils are highly concentrated oils extracted from aromatic plants such as lavender and rosemary. There are about 700 species of plants that contain usable essential oils, and there are several ways to extract them, the most common way is distillation. Essential oils are very expensive, but relatively inexpensive when it comes to home distillation.

Steps

Part 1 of 3: Preparation of Essential Oil Distillation Equipment

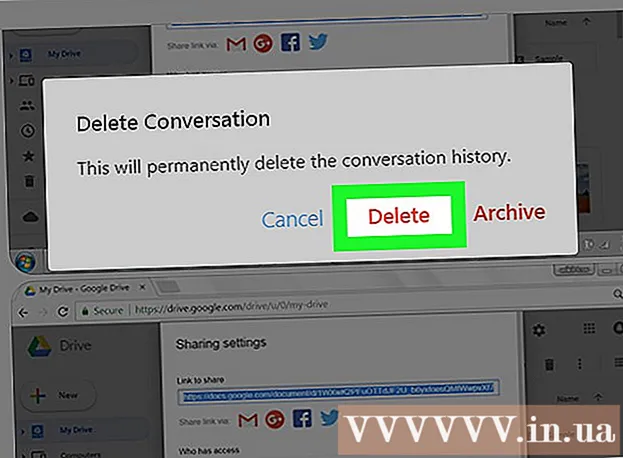

Buy essential oil distillation equipment. While it's difficult to find in a store (unless you have a specialty store near your home), you can easily buy them online. However, be aware that they can be very expensive, usually around a few million. If you're planning on producing large volumes of essential oils, it's also worth investing in a professional distillation equipment.

If you don't want to buy, you can make your own distillation unit. If you are going to make a distillation unit, there are many ways to do it, there are thousands of distillation designs, even today, many distillers are homemade. The main components of the distillation unit include:- The source of heat, usually direct fire

- Pressure cooker

- The glass tube is 10 mm in diameter

- The cold water tank for cooling and concentrating the steam goes through the pipe.

- Isolation device, used to separate essential oils from other substances that you do not want to mix into your final product.

If possible, use stainless steel and glass components. Do not use a plastic tube in place of a glass tube, as this can affect the quality of the essential oil. Some plants react poorly to copper, but tin-plated copper is suitable in all situations. You can also use aluminum but not on budwood, cloves, or plants whose oils contain phenol.

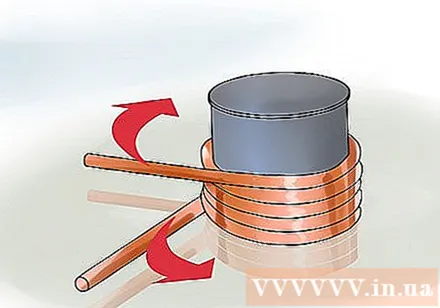

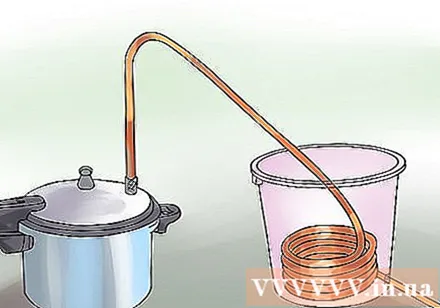

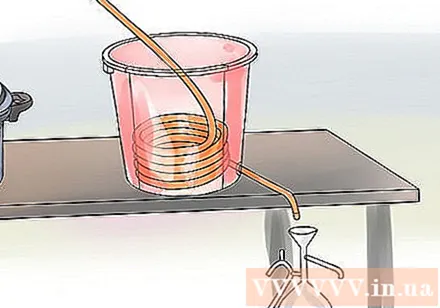

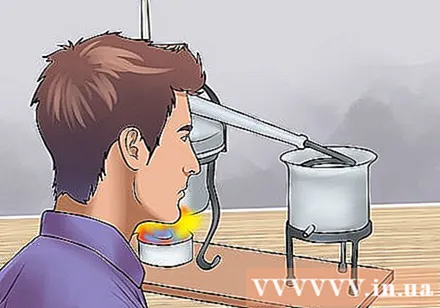

Bend the tube to pass through the cooler. You put medicinal plants in a pressure cooker to boil, the steam will be directed to the pipe. You can cool the steam into a liquid by soaking it in cold water or ice water. Depending on what you are using as the cooler, you will bend the pipes into different shapes. For example, if you are simply a pot, you will have to bend the tube into a coil in the pot. If you are using a large ice bucket, you will need to bend the tubing at a 90 degree angle so that the tubing goes from the wall of the bucket to the hole at the bottom of the bucket.

Connect the pipe to the pressure cooker valve. Use a short flexible hose, approximately 10 mm in diameter, of the pipe, to fit the two open ends. You can fasten the connector with a pipe brace from your hardware store.

- Be sure to cut the length of the tap long enough for a bend. If not, the pipe will be straight up into the sky, you should also have enough room to bend the pipe 90 degrees into the cooler.

Insert the tube into the cooling bottle. If you use a pot, roll the tubing completely inside the pot making sure to fill the pot when filled with cold water or ice. If you are using a bucket, make a small hole in the bottom to plug the hose. Close the gap in the hole with silicon or epoxy resin to prevent water from leaking, wetting out.

Place the tip of the tube into the isolator. When the distillation drops into the isolation device, it will do the rest of the work for you on its own. It will separate the essential oil from the rest that you don't want to mix into the final product.

Make sure the devices are firmly placed. Depending on the instrument you use and the shape of the tube, you may need to provide a safe and secure space for the distillation unit. Place the tube mounting swing to the mouth of the pressure cooker, insert the tube into the cooler, and place the tip of the tube into the mouth of the isolator. Make sure the hose bends at the correct angle and no tools are broken. advertisement

Part 2 of 3: Prepare Raw Trees

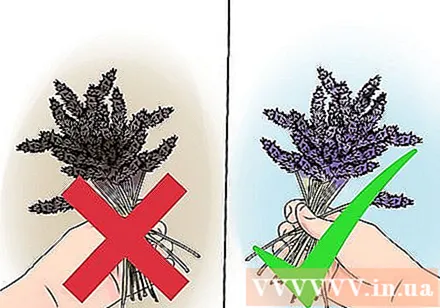

Determine the time to harvest the raw trees. The amount of essential oil in the plant depends on what stage of its life it is, so it's important to harvest the plant at the right time. You need to do a bit of research to know when to harvest the species of plants you want to distill. For example, lavender should be harvested when about half of the flowers on the plant have wilted. Rosemary, by contrast, needs to be harvested while the flowers are in full bloom.

Harvest properly. When figuring out when to harvest the most effective essential oils, you also need to research how to harvest them. Careless transportation, improper harvesting of plant parts, and at the wrong time of day can reduce the quantity and quality of essential oils. For example, you only need the blooming part of the rosemary plant when making essential oils. Throw away or use the rest of the tree for something else.

- Most essential oils are located in the oil glands, veins and secretory hairs, which are very fragile. If you disturb or break, you will get less essential oil. Handle plants carefully, as limited as possible.

When buying a tree, choose carefully. If you buy a tree that has been harvested, you have no control over the harvest. Choose plants that look healthy and have less breakage, and ask the seller about the timing of the tree's harvest. Usually, the plant is intact (not crumpled or ground into powder) is best.

- Although distillation will remove many impurities, herbicides and pesticides can contaminate your oil. So it's best to use organically grown plants whether you plant them or buy them.

Dry the raw plants. Drying reduces the amount of essential oil per plant, but can significantly increase the amount of essential oil extracted per batch due to an increase in material use. Plant drying should be done slowly and away from direct sunlight. Plants grown for sale such as lavender and mint can be left to dry in the field for about a day.

- The ideal drying method for each plant is not the same, but in general, you should not over-dry the plant. Dry in the shade or even in a dark room to minimize essential oil loss.

- Do not get the plants wet before distilling them. Distillate immediately after drying is complete.

- You may not need to dry the plants if you want to skip this step.

Part 3 of 3: Essential Oil Distillation

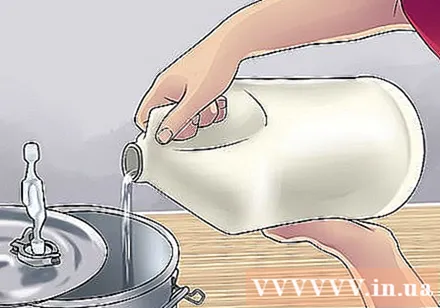

Fill the pot with water. If you make your own distillation unit, the part of the pot is your pressure cooker. Use clean, preferably filtered or distilled water and be as soft as possible. If you are using an industrial distillery, follow the manufacturer's instructions. If not, make sure you have enough water to complete the distillation. Depending on the type and quantity of raw plants, distillation can take place between half an hour and six hours or more after the water boils.

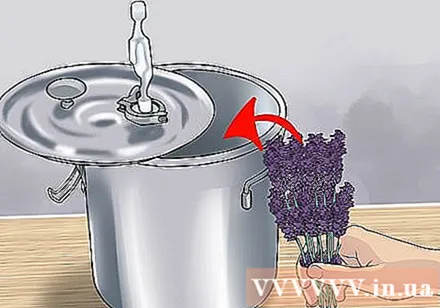

Add the ingredients to the water until the pot can hold. While the water should be sufficient not to dry out when boiled, ensure the plants are not affected even if tied. Make sure they do not block the exit of the steam through the hose attached to the pressure cooker swing. Leave a few centimeters in the pot for comfort.

- You don't have to cut or prepare the plant any other way, in fact, it will drain the essential oils.

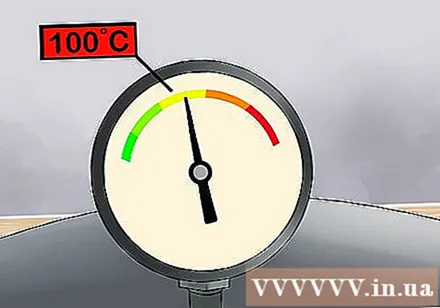

Boil a pressure cooker. Tighten the lid to allow the evaporation of the steam to pass through the pipe attached to the steam valve. Most plants release essential oils at 100 degrees C or 212 degrees F, the boiling point of water.

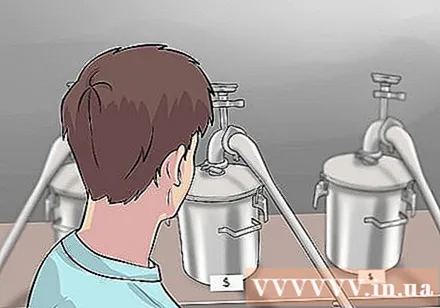

Look at the distillery. After a while the distillate passes through the condenser to the oil separator. You don't need to get your hands on this distillation, but you may want to check if the water is running out. Depending on the distillation time, you may need to change the water in the cold water container. If the heating pipe warms the water, replace it with cold water or fresh ice to allow cooling to continue.

Filter the obtained essential oil (optional). After the distillation is finished, you can filter the essential oils with a buckwheat or similar dry cotton cloth. Make sure the fabric is dry and clean, detergent left over, and dirt can damage essential oils.

- Don't be disappointed if you get very little essential oil from a large number of raw plants. Rates vary from plant to plant, but are often lower than first-time distillers thought.

Fill the jar with essential oil as quickly as possible. Most essential oils have a shelf life of at least a year or two, some have a very short shelf life. Use a clean funnel to fill the bottles with essential oils, making sure the bottles are clean before filling them with oil. Store essential oils in a cool, no light place.

- You also need to decide what to do with hydrosol. Another product obtained in the isolation device is hydrosol, which is distilled and drained with plant essences.

- Some hydrosol products, like rose water and lavender, are available.

- If you do not want to retain the hydrosol, you can pour it into the distillation pot next time, provided that the distillation is done immediately afterwards. If not, dump it.

Advice

- Essential oils have a very high concentration, and are often recommended as clear dilutions conductive oil before applying to the skin. The most common carrier oils are almond oil and grape seed oil, and there are many other oils you can use. They can be added during bottling or mixed with virgin oil just before serving. The latter is often preferred because there are situations where you do not need to dilute the essential oils, and furthermore, the carrier oil usually has a shorter shelf life than the essential oil.

Warning

- Most essential oils are not drinkable, especially undiluted ones, many need to be diluted even for external use. Furthermore, some essential oils are also toxic. For more details, see the external links.

- For most flowers, when distillation, skip drying and distilling immediately after harvest.

- Do not distill one batch for too long (see instructions for specific plant species) as this produces a little more essential oil, but can damage the batch by producing unwanted chemical compounds.

- If the plants are grown organically it doesn't mean that pesticides or herbicides are not being used; just don't take conventional synthetic drugs (sometimes synthetic drugs are less toxic than organic drugs).Trying to find a planter in your area can help you understand the planting process.

- When drying raw plants, be careful not to contaminate them with dirt or other contaminants. Contamination will degrade the essential oils and make them unusable.

What you need

- Distillation apparatus, including at least: distillers, condensers, cookers or other heat sources, and oil separators.

- Glass tubing for connection of distillation elements

- Raw material plants to extract essential oils

- Bottles made of opaque glass or stainless steel to store essential oils