Author:

Helen Garcia

Date Of Creation:

17 April 2021

Update Date:

1 July 2024

Content

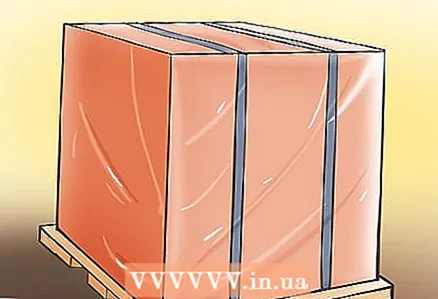

Shrink wrap (more precisely, stretch wrap) is a packaging method used in the industry to secure parts to a pallet. This involves using a roll of thin, stretchable plastic wrap to provide multi-layer retention of the fastener. Often people do not delve into this routine work and the results are not as effective as they could be.

There is the art and etiquette of wrapping objects in a pallet with shrink wrap. Read this article to learn about the correct technique and time-saving pallet wrapping.

Steps

1 Choose the right pallet. Parts must be shipped or stored in a sturdy pallet. Select the correct pallet size to accommodate the required number of boxes or other wrapping materials. This can keep the film from tearing at sharp corners.

1 Choose the right pallet. Parts must be shipped or stored in a sturdy pallet. Select the correct pallet size to accommodate the required number of boxes or other wrapping materials. This can keep the film from tearing at sharp corners. - Make sure the items you are going to wrap are as close to each other as possible. If they are left with empty space to move around, the wrapper will be loose and ineffective. Fix objects opposite each other.

2 This is easy to do. Place the wrapping pallet on the small empty pallet rack. This will help make it easier to wrap the pallets the way you want without bending over. Set the pallet diagonally at a 45 degree angle (so the bottom of each corner overlaps the top edge of the bottom stack). Make sure the pallet does not wobble!

2 This is easy to do. Place the wrapping pallet on the small empty pallet rack. This will help make it easier to wrap the pallets the way you want without bending over. Set the pallet diagonally at a 45 degree angle (so the bottom of each corner overlaps the top edge of the bottom stack). Make sure the pallet does not wobble!  3 Fastening the wrapping paper. Take a roll of wrapping paper and cut about 90 cm of plastic. Press about 20 cm and wrap with string or string around one corner of the pallet. Take your time to tie the knot. Just press firmly while you fold the rest. The plastic sticks just enough to prevent deployment.

3 Fastening the wrapping paper. Take a roll of wrapping paper and cut about 90 cm of plastic. Press about 20 cm and wrap with string or string around one corner of the pallet. Take your time to tie the knot. Just press firmly while you fold the rest. The plastic sticks just enough to prevent deployment.  4 Strengthen the foundation. Wrap the base of the pallet again in the same direction as the first time. Make sure the number of turns is enough to prevent the plastic from slipping. This is the most important step as it is necessary to keep the goods on the pallet. Wrap this base at least 4-5 times, making sure the edge of the wrapper goes at the corners.Stretch the roll tightly before turning.

4 Strengthen the foundation. Wrap the base of the pallet again in the same direction as the first time. Make sure the number of turns is enough to prevent the plastic from slipping. This is the most important step as it is necessary to keep the goods on the pallet. Wrap this base at least 4-5 times, making sure the edge of the wrapper goes at the corners.Stretch the roll tightly before turning.  5 Secure the load. In general, you need to connect all pallets into one block. They should move as one whole, without impacts. With this in mind, move upward from the base so that the lower boxes dock exactly with the pallet. Continue packing so that the next layer is firmly attached to the first, and so on. Remember to stretch the film as much as possible.

5 Secure the load. In general, you need to connect all pallets into one block. They should move as one whole, without impacts. With this in mind, move upward from the base so that the lower boxes dock exactly with the pallet. Continue packing so that the next layer is firmly attached to the first, and so on. Remember to stretch the film as much as possible.  6 Test and completion. When you get to the top of the pallet, you can finish on it or wrap the pallet at the bottom. To determine, try pressing down on the top boxes to see if the load is tight or loose. If you see ripples on the plastic or a wobble in the stack, then you either didn't wrap the pallet tightly enough, or you need more layers. Wrap it a few more times, working down to the base. When the film is taut, tear it off the roll and fold the end under the edge of one of the layers of the wrapper. This will avoid unwrapping.

6 Test and completion. When you get to the top of the pallet, you can finish on it or wrap the pallet at the bottom. To determine, try pressing down on the top boxes to see if the load is tight or loose. If you see ripples on the plastic or a wobble in the stack, then you either didn't wrap the pallet tightly enough, or you need more layers. Wrap it a few more times, working down to the base. When the film is taut, tear it off the roll and fold the end under the edge of one of the layers of the wrapper. This will avoid unwrapping.

Tips

- Do not tie the packaging on the pallet in a knot! It's a matter of etiquette and economy. Not only will this take longer, but it will then require someone to carry a knife to break the knot. The plastic film adheres well to each other, so knots are not needed.

- For a little extra strength, after a full wrap, move to the center of the pallet and wrap again. Flip the film over as you go to create an X-shaped wrap. This will add stability and strength.

Warnings

- Do not wrap too loosely as the plastic wrap may stretch during shipping. Always stretch the film until it almost breaks. The more "stretched" it is, the more firmly it will hold the product.