Author:

Bobbie Johnson

Date Of Creation:

2 April 2021

Update Date:

1 July 2024

Content

- Steps

- Part 1 of 2: Preparing the work area

- Part 2 of 2: Silver Compound

- Tips

- Warnings

- What do you need

Soldering two pieces of silver or repairing a crack in a silver object requires different materials and techniques than most other metals. Even if you already have a solder zone ready to go, read or skim through this section to find out what changes you might need before you start soldering silver.

Steps

Part 1 of 2: Preparing the work area

1 Find a charcoal brazing brick or other suitable work surface. Soldering will fail if too much heat is lost in the air or into the work surface, so you will need to find a special surface with low thermal conductivity. Charcoal bricks may be the best option for brazing silver, as they reflect heat, creating the heat that silver requires. Magnesia bricks or kiln bricks are other common options that will probably last longer in soldering projects than coal bricks.

1 Find a charcoal brazing brick or other suitable work surface. Soldering will fail if too much heat is lost in the air or into the work surface, so you will need to find a special surface with low thermal conductivity. Charcoal bricks may be the best option for brazing silver, as they reflect heat, creating the heat that silver requires. Magnesia bricks or kiln bricks are other common options that will probably last longer in soldering projects than coal bricks. - They can be purchased from craft stores or jewelry stores; they are similar in shape and size to ordinary building bricks.

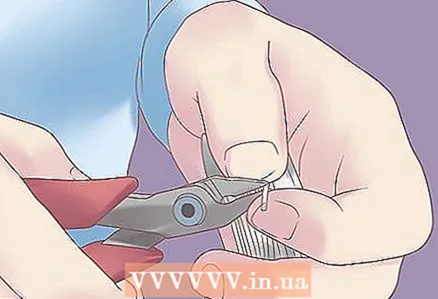

2 Buy silver solder. Silver solder is an alloy of silver and other metals designed to bond with silver but melt at a lower temperature. You can buy it as a package of cut pieces, or buy it in sheet or wire form and cut into 3 mm pieces with wire cutters. Do not try to use lead solder when soldering silver, as this will not work - it will be difficult to remove.

2 Buy silver solder. Silver solder is an alloy of silver and other metals designed to bond with silver but melt at a lower temperature. You can buy it as a package of cut pieces, or buy it in sheet or wire form and cut into 3 mm pieces with wire cutters. Do not try to use lead solder when soldering silver, as this will not work - it will be difficult to remove. - Attention: avoid working with silver solder containing cadmium, which can cause health problems if fumes are inhaled.

- If you are filling the crack, you can use a less pure, "lightweight" silver solder as it melts at a lower temperature. To bond the two pieces together, respectively, use "medium" or "hard" silver solder with a high silver content to create a stronger bond. Note that there are no industry-wide definitions for these terms; if you are changing brands and want similar results, look at the silver percentage.

3 Use a torch, not a soldering iron. Do not use soldering irons as they are designed for lower melting point lead solder and can damage precious metals. Purchase a small acetylene torch from a hardware store, preferably with a flat, "chisel" tip rather than a pointed one.

3 Use a torch, not a soldering iron. Do not use soldering irons as they are designed for lower melting point lead solder and can damage precious metals. Purchase a small acetylene torch from a hardware store, preferably with a flat, "chisel" tip rather than a pointed one. - Silver quickly removes heat from the flame. Accordingly, a small torch tip can make the soldering process slower.

4 Select a general purpose flux or a "hardfacing" flux. "Flux" is necessary for cleaning the silver surface and aids in the transfer of heat. It also helps remove oxide from the silver surface that can make bonding difficult. You can use a general purpose flux, or "soldering flux" specifically for silver or jewelry.

4 Select a general purpose flux or a "hardfacing" flux. "Flux" is necessary for cleaning the silver surface and aids in the transfer of heat. It also helps remove oxide from the silver surface that can make bonding difficult. You can use a general purpose flux, or "soldering flux" specifically for silver or jewelry. - A "hardfacing" flux is used for joining at high temperatures in which the surfaces of metal objects are themselves chemically altered. This is why even jewelers say that it is technically more correct to refer this process to "brazing" rather than "surfacing".

- It doesn't matter what form you buy the flux (paste or liquid).

5 Use a fan for ventilation as needed. Open windows or turn on a fan to minimize the amount of smoke you inhale by moving air over and away from your work surface. Keep strong jets away from the object itself, otherwise the cooling effect can make the soldering process difficult.

5 Use a fan for ventilation as needed. Open windows or turn on a fan to minimize the amount of smoke you inhale by moving air over and away from your work surface. Keep strong jets away from the object itself, otherwise the cooling effect can make the soldering process difficult.  6 Find tweezers and copper tongs. Copper tongs are recommended as they can handle high temperatures and will not corrode or spoil the pickling solution described below. Tweezers are useful for holding silver objects in place and can be made from any metal.

6 Find tweezers and copper tongs. Copper tongs are recommended as they can handle high temperatures and will not corrode or spoil the pickling solution described below. Tweezers are useful for holding silver objects in place and can be made from any metal.  7 Take precautions with glasses and an apron. Safety goggles are essential to protect your eyes from accidental splashes as you may need to take a close look at the connection. A denim or canvas apron minimizes the chance of garments catching fire.

7 Take precautions with glasses and an apron. Safety goggles are essential to protect your eyes from accidental splashes as you may need to take a close look at the connection. A denim or canvas apron minimizes the chance of garments catching fire. - Avoid loose or loose clothing. Roll up long sleeves and a tie, tuck away long hair before you get to work.

8 Prepare a container of water. You need a container of water to rinse the silver at the end of the process. Make sure it is deep enough to contain the entire subject.

8 Prepare a container of water. You need a container of water to rinse the silver at the end of the process. Make sure it is deep enough to contain the entire subject.  9 Heat the container with the "seed".’ Purchase a "seed" or acid solution used for soldering, always labeled for silver. It usually comes in powder form. Just before you start soldering, dissolve the powder in water and use a saucepan or special "pickling pot" to heat it according to the manufacturer's instructions.

9 Heat the container with the "seed".’ Purchase a "seed" or acid solution used for soldering, always labeled for silver. It usually comes in powder form. Just before you start soldering, dissolve the powder in water and use a saucepan or special "pickling pot" to heat it according to the manufacturer's instructions. - Do not use a saucepan, microwave, or oven that you intend to use again for cooking. The pickling solution can leave a metallic odor or even traces of toxic materials. Never leave steel in contact with pickling solution.

- Most prepared pickling solutions can be stored for several weeks.

Part 2 of 2: Silver Compound

1 Cleanse the silver. Degreasers are recommended for oily or heavily soiled silver. If there are signs of oxidation on the surface, it may be necessary to place the silver in a pickling solution before brazing. If desired, you can use 1000 grit sandpaper to roughen the joint surface.

1 Cleanse the silver. Degreasers are recommended for oily or heavily soiled silver. If there are signs of oxidation on the surface, it may be necessary to place the silver in a pickling solution before brazing. If desired, you can use 1000 grit sandpaper to roughen the joint surface.  2 Apply flux to the joint. Prepare the flux according to package directions if not ready to use. Use a small brush to apply flux to the silver object (s). Some people only apply it where solder will be present in order to limit it from flowing to unnecessary places. Others prefer to apply flux over a large area to minimize the risk of fire damage, but this is not recommended for beginners.

2 Apply flux to the joint. Prepare the flux according to package directions if not ready to use. Use a small brush to apply flux to the silver object (s). Some people only apply it where solder will be present in order to limit it from flowing to unnecessary places. Others prefer to apply flux over a large area to minimize the risk of fire damage, but this is not recommended for beginners. - It is recommended to use a small amount of flux in a separate container, as repeatedly dipping the brush into the main bottle can add dirt and affect its function.

3 Arrange the silver pieces for the connection. Place two pieces next to each other on a soldering brick. Arrange them the way you want them to be connected, note that they must physically touch in order to join correctly.

3 Arrange the silver pieces for the connection. Place two pieces next to each other on a soldering brick. Arrange them the way you want them to be connected, note that they must physically touch in order to join correctly.  4 Place the solder on the joint. Use tweezers to take a piece of solder and carefully place it on one end of the crack or break. When the solder is melted, it will spread over the entire surface to which the flux was applied, so you do not need to cover the entire length of the slot with solder.

4 Place the solder on the joint. Use tweezers to take a piece of solder and carefully place it on one end of the crack or break. When the solder is melted, it will spread over the entire surface to which the flux was applied, so you do not need to cover the entire length of the slot with solder.  5 Heat the solder until it melts. Light the burner and set it to the highest temperature. Start the soldering as follows: bring the torch to the soldering point at a distance of 10 cm and move it in small, constant circular movements to ensure uniform heating of all elements. Slowly bring the flame closer to the solder point, concentrating your attention on the solder. When the solder reaches its melting point, it will quickly melt and flow onto the flux-treated parts of the silver.

5 Heat the solder until it melts. Light the burner and set it to the highest temperature. Start the soldering as follows: bring the torch to the soldering point at a distance of 10 cm and move it in small, constant circular movements to ensure uniform heating of all elements. Slowly bring the flame closer to the solder point, concentrating your attention on the solder. When the solder reaches its melting point, it will quickly melt and flow onto the flux-treated parts of the silver. - If one of the objects to be joined is thicker than the other, heat the back of the thick object first until the solder begins to melt, then quickly heat the thin one.

- If necessary, use tweezers to hold objects in place, but place them away from the flame. You may need to hold onto small, thin areas of silver to allow heat transfer, preventing the thin area from melting.

6 Submerge the object in water, then submerge it in the pickling solution. Let the object cool for a minute, then cool it further by dipping it in a bath of water. The "pickling solution" described in the work area section is an acid bath used to clean jewelry after soldering. Dip the silver into this bath using copper tongs and let it sit for a few minutes to remove the flux and oxidation. Avoid contact with skin, clothing or steel tools, as the pickling solution can be corrosive.

6 Submerge the object in water, then submerge it in the pickling solution. Let the object cool for a minute, then cool it further by dipping it in a bath of water. The "pickling solution" described in the work area section is an acid bath used to clean jewelry after soldering. Dip the silver into this bath using copper tongs and let it sit for a few minutes to remove the flux and oxidation. Avoid contact with skin, clothing or steel tools, as the pickling solution can be corrosive.  7 Rinse out the silver. Rinse the connected silver piece with water. Wipe dry with a clean cloth. If the process has been completed correctly, the silver should be attached firmly.

7 Rinse out the silver. Rinse the connected silver piece with water. Wipe dry with a clean cloth. If the process has been completed correctly, the silver should be attached firmly.

Tips

- If using too much solder has resulted in lumps, use a file to remove them.

- If the solder does not flow properly, stop, let the parts cool, and start over. Clean them thoroughly with a cloth and pickling solution

Warnings

- If you spill acidic pickling solution on your skin or clothing, rinse thoroughly with cold running water.

What do you need

- Solder brick

- Silver solder

- Nippers

- Silver details

- Flux

- Water

- Glass jar

- Small brush

- Tweezers

- Burner

- Pickling solution

- Copper tongs

- Clean cloth