Author:

Sara Rhodes

Date Of Creation:

18 February 2021

Update Date:

1 July 2024

Content

Jewelry casting is the process of pouring molten metal into casting molds. It is commonly referred to as investment casting because a mold is created from a wax model, which is then burned out, leaving an empty space within the mold. This technology has been used for several thousand years and is still widely used by professional craftsmen and amateur artisans to make replicas of jewelry and art objects. If you want to create your own jewelry using casting, follow the steps in this article.

Steps

1 Select a model for casting. A model is a piece of jewelry that you want to use to make a mold. As a model, you can choose any piece of jewelry you would like to create a copy of.

1 Select a model for casting. A model is a piece of jewelry that you want to use to make a mold. As a model, you can choose any piece of jewelry you would like to create a copy of.  2 Make a rubber copy of your chosen model.

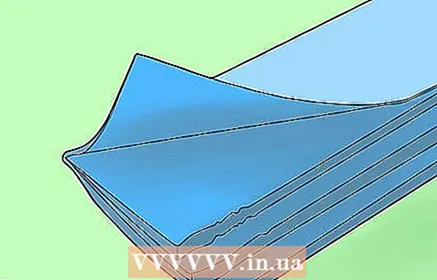

2 Make a rubber copy of your chosen model.- Purchase green injection molding rubber from your local hardware store or arts and crafts store. There are a variety of molding sands commercially available to suit all tastes, so you can experiment with different mixes to find the one that best suits your needs.

- Press the model into a large enough piece of sand. The rubber must completely wrap around the model to ensure accurate reproduction of the decoration. The sand will be soft and pliable before firing, so you don't have to worry about damaging your jewelry.

- Following the manufacturer's instructions, heat the rubber to cure it. As a result, the material will feel like a tight bouncy ball to the touch.

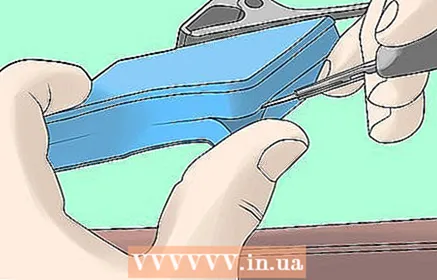

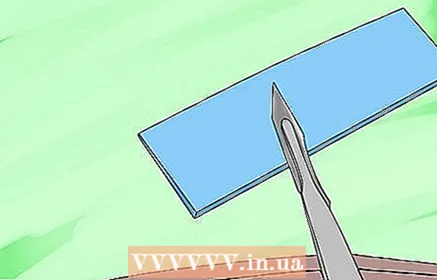

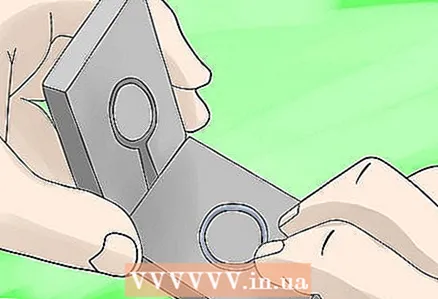

- Cut the model out of the enclosing shape using a sharp scalpel. Cut the rubber mold around the center around the model so that the mold opens in half, like a book. At this point, be careful not to damage the model with the scalpel.

- Remove the model carefully without damaging the mold, as any irregularities in the mold will lead to rejects during further casting.

- Cut a shallow channel in each mold half that leads to the cavity left by the model. These channels should align with each other when you close the mold, thus creating an opening for you to insert the syringe into.

3 Fill the mold with melted wax. Use a craft wax of a kind purchased from a hardware store or arts and crafts store to do this. There are many waxes with different melting points, so experiment with them to see which one works best for you.

3 Fill the mold with melted wax. Use a craft wax of a kind purchased from a hardware store or arts and crafts store to do this. There are many waxes with different melting points, so experiment with them to see which one works best for you. - Melt the wax in a double boiler, following the instructions on the packaging for the melting point.

- Using a medical syringe, inserting it into the previously made channel, fill the mold with molten wax.

4 Wait for the wax to harden completely. The setting time of the wax may vary and depends on the specific brand you purchased. Please refer to the instructions for the required time.

4 Wait for the wax to harden completely. The setting time of the wax may vary and depends on the specific brand you purchased. Please refer to the instructions for the required time.  5 Remove the resulting wax-up from the rubber mold. It will serve as your model for casting your lost wax jewelry.

5 Remove the resulting wax-up from the rubber mold. It will serve as your model for casting your lost wax jewelry.  6 Make a stand for the model. Cut out a thin rod from the wax enough to support the wax-up and attach it to the model with melted wax.

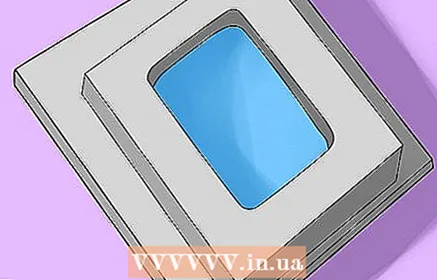

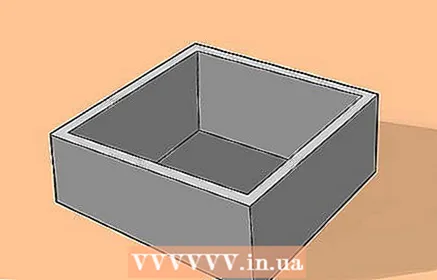

6 Make a stand for the model. Cut out a thin rod from the wax enough to support the wax-up and attach it to the model with melted wax.  7 Attach the wax-up to the bottom of the investment ring (metal container) with melted wax. The model must be securely attached to the bottom of the investment ring with the wax rod pointing up. Everything is now ready for casting.

7 Attach the wax-up to the bottom of the investment ring (metal container) with melted wax. The model must be securely attached to the bottom of the investment ring with the wax rod pointing up. Everything is now ready for casting.  8 Following the manufacturer's instructions, dilute the dry gypsum-based refractory mixture with the required amount of water.

8 Following the manufacturer's instructions, dilute the dry gypsum-based refractory mixture with the required amount of water. 9 Pour the mixture into the flask so that it completely covers the wax-up.

9 Pour the mixture into the flask so that it completely covers the wax-up. 10 Wait for the mixture to flow and fill the investment ring evenly.

10 Wait for the mixture to flow and fill the investment ring evenly. 11 Place the flask whole in a kiln heated to about 600 degrees Celsius (1100 degrees Fahrenheit). As a result, the refractory mixture will harden, and the wax will evaporate, leaving behind a void in the center of the flask, which exactly repeats the shape of the model.

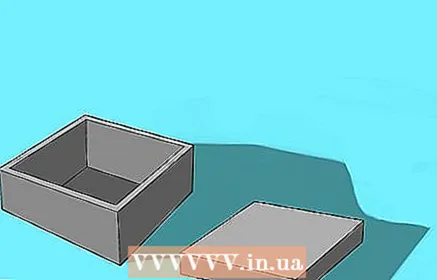

11 Place the flask whole in a kiln heated to about 600 degrees Celsius (1100 degrees Fahrenheit). As a result, the refractory mixture will harden, and the wax will evaporate, leaving behind a void in the center of the flask, which exactly repeats the shape of the model.  12 Remove the mold from the investment ring.

12 Remove the mold from the investment ring. 13 Pour metal into the mold.

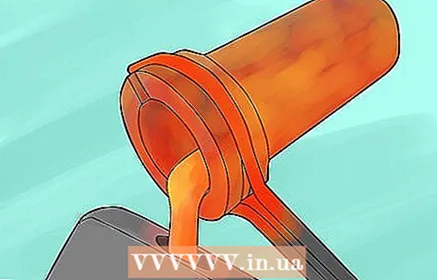

13 Pour metal into the mold.- Place the metal of your choice in a pouring crucible and melt it in a metallurgical furnace. The temperature and time will depend on which metal you choose to use.

- Pour molten metal from the pouring crucible into the mold through the hole left in the mold in place of the wax rod.

14 Let the metal cool.

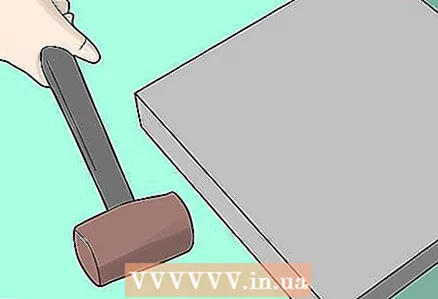

14 Let the metal cool. 15 Tap the mold gently with a hammer until it breaks and you can reach the casting.

15 Tap the mold gently with a hammer until it breaks and you can reach the casting. 16 Polish the resulting casting with a metal polishing wheel to remove any unevenness or roughness left over from the casting.

16 Polish the resulting casting with a metal polishing wheel to remove any unevenness or roughness left over from the casting.

Tips

- In addition to your hardware store or arts and crafts store, you can order casting wax from your jewelry supplier. You can find such providers in the telephone directory or on the Internet.

- You can make your own original piece of jewelry from wax by carving out small parts using dental and / or sculptor's tools. You can find hard wax and sculpting tools at an arts and crafts store. There are many types of wax, which vary in hardness. Experiment with them until you find one that works for you.

What do you need

- Uncured rubber for molding

- Scalpel

- Craft wax

- Double boiler

- Medical syringe with dosage

- Flask

- Gypsum-based refractory mixture for casting

- Kiln

- Molten metal

- A hammer

- Polishing wheel for metal

- Metallurgical furnace

- Draft crucible