Author:

Monica Porter

Date Of Creation:

19 March 2021

Update Date:

1 July 2024

Content

There are times when you need to break a piece of concrete to repair underground pipes, or when you want to renovate a concrete yard into a garden to create a green space. With a little effort and use of the right tools, you can remove entire slabs or just a small portion. After that, all you need to do is load the concrete debris onto the car to transport it to the leveling area.

Steps

Method 1 of 3: Remove the entire concrete slab

Call utility companies. Be sure to call your local utility companies to make sure there are no power lines or pipes underneath the concrete floor. Please hire a professional if possible. Digging soil on gas or power lines can be dangerous.

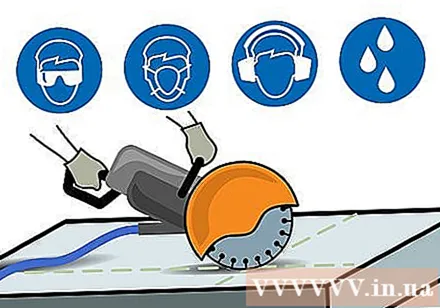

Use safety equipment. Smashing concrete will create harmful dust and sharp debris, so protect yourself and your coworkers with safety goggles, dust masks or masks, steel toe shoes or boots, gloves. thick arms, and thick fabric to cover hands and feet.- If you are going to use an electric tool like a chisel machine, you should use earplugs.

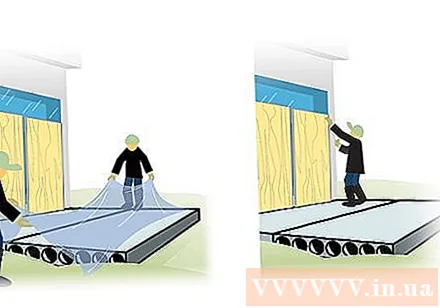

Use tarpaulins over concrete slabs to protect fragile objects. Be careful when using tarpaulin as sometimes it can cause you to slip or trip. However, a tarpaulin cover is necessary if you are working near fragile objects or structures.- If you are working in a large space away from other structures and fragile objects, coverings may not be needed.

- Concrete debris can be thrown very far due to the impact of hammers and tools. If you are unsure, shield the space around you.

- If you don't use tarpaulins, use plywood to protect windows or other fragile objects nearby.

Find a large crowbar. Regardless of whether you are using a sledgehammer or a concrete chisel, you will often need to use crowbar to pull off separate pieces of concrete. Demolition work will take the least amount of time if one person breaks the concrete and another person follows to remove the broken pieces.

Use sledgehammer to break thin concrete. If the concrete is only 10cm thick, then use a sledgehammer. Start at a crack, corner or edge of the slab, and remember that thick concrete will break most easily near the edge.

- Don't try to swing or raise the hammer overhead; Instead, keep the hammer at shoulder level and hit the concrete floor.

- Use crowbar to trap separated concrete blocks after being broken. Then, remove the concrete slabs from the walkway to avoid the risk of tripping.

- You should use a chisel machine if after 10 minutes the concrete still does not crack significantly and you are exhausted.

Dig underneath the slab if the concrete is too hard. “Digging underneath” or removing soil under the slab will make the concrete easier to crack. Use a shovel to shovel the soil below the edge of the concrete floor, then use a hammer to break the edge of the floor.

- The more soil you remove under the slab, the easier it will be to break the concrete. However, just removing a little soil will make the concrete more fragile.

- While shoveling the soil, use a sprinkler to loosen the soil and flush the soil with water.

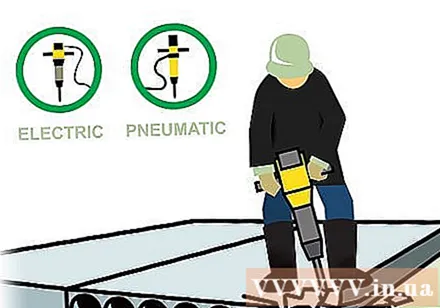

Using concrete chisels. The 27kg concrete chisel machine is enough to handle almost any household chore. You should only hire heavy air chisels for very thick or hard concrete.

- Only use chisels to break concrete. The chisel tip helps to focus the force on the concrete, making it more fragile.

- You just let the machine's self-weight handle the job, without having to press it down to generate more force. Pressing the chisel tip may damage the tool or jam the chisel.

- If the concrete does not crack immediately stop the machine and move to another location a few centimeters away. Continued operation of the machine may result in the chisel tip getting stuck.

- Break the concrete into pieces 5-8 cm apart to reduce the risk of chiselling.

- Use crowbar to trap separated concrete pieces after cracking.

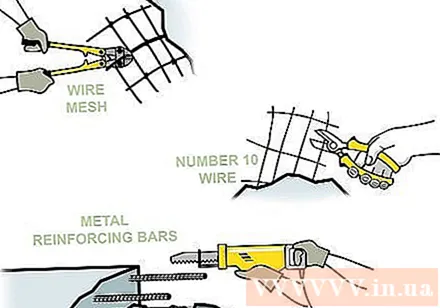

Treatment of wire mesh or reinforcement in concrete. You may encounter steel reinforcement bars in the concrete after cracking. Treat them while separating the concrete blocks:

- If the concrete is reinforced with wire mesh or steel bars welded together, you need to use bolt cutting pliers to cut the reinforcement steel apart. You can use the pliers to cut steel mesh 10.

- Reinforced steel welded together is much harder to cut. You should then use a rotary saw or a disc saw to cut the welded reinforcement.

Use a hoe to remove the jammed concrete. If the pieces of concrete still stick together and make it difficult for you to break the surrounding area, remove the broken pieces. You can then use a pickaxe to separate the sticky patches:

- Swing the pointed end of the hoe into the crack between the two concrete plates and the lever.

- When the crack is large enough, switch to using a large, flat end to fully separate it.

- Seven opposite sides of each piece of concrete if it still won't budge.

Method 2 of 3: Remove a small portion of concrete

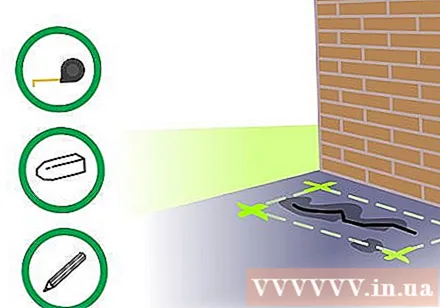

Determine where to break the concrete. If you are looking for a broken water pipe and can predict the location, it will save a lot of effort and cost. You need to look for the following:

- For pipeline problems, try to find the location and depth of the underground pipe. Find an outdoor drain, drain hose, or use a plumbing detector.

- For potable water, find a location where water is leaking from a crack in a concrete floor or seeping through the edge of a concrete floor.

- For power lines, you may have to find an insulated pipe outside an area with a concrete floor and dig it up to see where the power line is going.

- For other incidents, you need to check the construction drawings with the local authorities or ask the contractor to issue the construction drawings of the house.

Mark the spot of the piece of concrete you plan to demolish. You should measure the distance from the edges of the concrete floor to create a symmetrical and parallel hole, making future patches less prominent. Use a pencil or chalk to mark the spot.

- Since you don't know what's underneath that concrete, leave plenty of space around the repair area to avoid causing further damage.

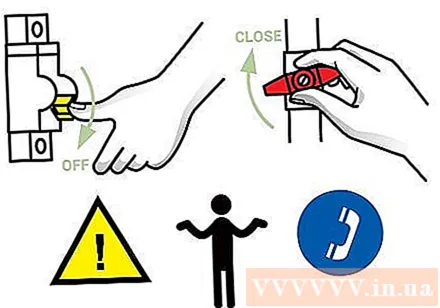

Close all system related utilities. If you are digging at a line or pipe site, you must close or disconnect the water lines or power lines before starting. You certainly don't want an electric shock, to let water overflow or leak gas.

- Be sure to call the utility company to find power lines and other dangerous structures before undertaking a project that requires excavation.

Cut in a straight line, the deeper the better. First you need to hire a concrete cutter. Cut a straight line by hand to create a neat concrete edge after the concrete floor is removed. If you are looking for pipes that break water then widen the hole after breaking down the first piece of concrete.

- Take particular care while cutting concrete. Concrete cutters are so powerful that they can cause serious injury or physical harm, or even death if not used properly.

- Always wear a facemask or mask to protect the lungs from cement dust, and always follow the tool's instructions.

- If possible, use a circuit breaker with an inlet hose to limit dust spread into the air and prevent the risk of cutting discs.

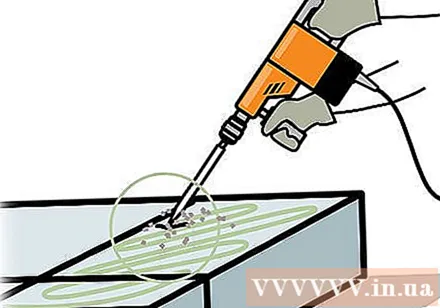

Breaking concrete near the cut area. Use a heavy hammer drill or chisel mounted on a rotary hammer to break concrete near the line you just cut. Tilt the chisel tip so that the concrete you want to remove will come off, not the concrete that needs to be retained.

Deepen. Still use the same tool to break the area around the cut, dig deeper until it reaches the bottom of the concrete slab. This is the hardest part because the pieces of concrete you want to break cannot be broken until there is space for them to expand.

- You may have to leave too hard concrete areas until the adjacent concrete has broken and come off.

Punch inward to widen the opening. Once you have created a gap between the concrete to be removed and the remaining concrete, continue chiseling with the tool. Open the gap to at least 8 cm or wide enough to remove the concrete pieces.

- Keep the tip of the chisel tilted into the original hole and start punching around the perimeter of the hole, so the chisel will not go straight down into the hole.

- If the chisel goes too deep, the chisel tip will get stuck in the hole and you cannot pull out.

- If the chisel is stuck then you need to use a new chisel to break the surrounding concrete and remove the other chisel.

Break concrete with sledgehammer or concrete chisel machine. When the gap is large enough to avoid damaging the concrete you want to retain, you can use the techniques described in this section to remove the entire slab.

- Use crowbar for fastest and most effective results.

- Do not use a chisel machine or similar electrical equipment if the concrete site is near a water pipe, power cord or gas line.

- Take the broken concrete blocks out of the hole as the amount of concrete increases so you can work more comfortably, and easily spot the pipes or power lines.

- Use bolt cutters to cut the reinforcing wire mesh and use a disc saw to cut the bars.

Clean the hole wall. After removing all the concrete, you will trim the concrete on the wall of the hole to create a more even surface. This is to ensure the quality of the subsequent fix (or to make the edge of the concrete more visible if you do not intend to patch).

Find damaged piping (depending on the case). If you are looking for broken pipes or power lines, look for signs of concrete breakage, like puddles or traces of water. If you see the pipe, you need to continue breaking concrete along the pipe until you find the damaged section.

- When digging closer to the location of the damaged pipe or power line, you should slow down and swing the hammer more accurately to avoid causing further damage.

- To protect pipes and power lines, try to avoid hammering on concrete sections that lie directly above them.

- Avoid hammering on cast iron pipes or PVC pipes because these materials are brittle and can easily be broken.

Method 3 of 3: Handling of concrete chips

Use debris for leveling. If there is a large hole in the yard, you can use debris to fill it. Cover the pipes or other objects with soft soil to avoid damage when they come into contact with backfilled concrete debris.

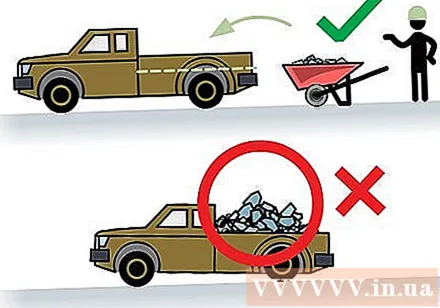

Use a wheelbarrow or large stroller. Transport the debris to a larger container by a large wheelbarrow. Concrete is so heavy that it can damage a small wheelbarrow, or you can use a trolley to transport it. With a stroller, you only need to move concrete blocks a few centimeters instead of lifting them onto a wheelbarrow.

- Don't overload the wheelbarrow to prevent it from overturning and create more jobs for you. Transporting many times in less quantity will avoid overload.

- Consider renting an electric wheelbarrow.

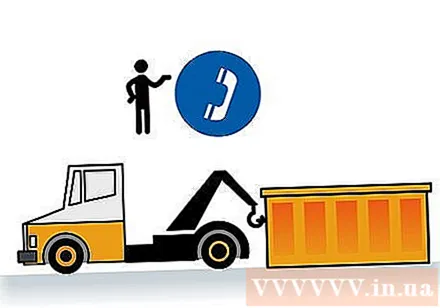

Lease of large trash cans at waste material handling companies. If you need to dispose of a large amount of concrete then definitely rent a large trash can. Many waste disposal companies reduce their service fees for pure concrete waste.

- You need to ask in advance how much concrete you can put in the bin, otherwise you will have to take out any excess concrete or pay extra for them to handle.

Contact the backfill to inquire about the cost of the disposal of concrete. In some places, only landfills that accept construction materials receive concrete treatment. The disposal fee for concrete at these backfill sites can be quite high, so you should ask in advance.

Transporting concrete to the landfill site. Be careful because a truck may not be able to carry as much concrete as you might think. Using large capacity trucks and don't filled the vehicle's body. Half a tank is usually fine for larger vehicles, with smaller trucks it's a good idea to fill a quarter full.

- You can also use a trailer for a truck, but be especially cautious in that case. The drawer is too heavy and may crash into the vehicle or spill material out.

- Construction materials companies can get free cages if you call first and agree to do it yourself.

Provide debris for other construction projects. Concrete shavings can be used to lift floors or structures. You can also use concrete slabs that look like curbing material to create walkways. Paint the uniquely shaped concrete patches to decorate the garden.

- Alternatively, you can make a circle of concrete blocks to create a fire in your backyard.

Advice

- If you are breaking concrete at a walkway or curb, cut the expansion joints on the sides. Not only are these positions thinner, but also have a clear shape that makes it easier to pour new concrete.

- Find specialized demolition tools at a tool and equipment rental store if you only need one use, as they are expensive.

- For concrete arrays over 1.5-2 square meters, hiring concrete chisels or workers will be the fastest option.

- Use a smaller and lighter tool to break concrete near pipes or other fragile structures.

- Use the largest hammer drill or rotary hammer suitable for the job.

- Avoid damaging the reinforcing bars or wire mesh if possible. Damage to the reinforcement steel can adversely affect the adjacent concrete.

Warning

- The rotary drill creates a large torque. Be sure to use the auxiliary handle supplied with this unit.

- Read all the tool manufacturer's instructions and follow the safety rules. Do not use the device until you understand how to operate it.

- Wear a mask or dust mask when cutting dry concrete. If possible, use a wet cutting system. Concrete contains silica dust, which can damage the respiratory system. Old concrete may also contain asbestos; Please test before starting work if you are in doubt about the concrete composition.

What you need

- Bolt cutting pliers (if there is a wire mesh)

- Concrete cutters

- Dust masks or masks

- Earplugs (if working with electrical equipment)

- Hammer drill

- Thick gloves, boots or clothing

- Large crowbar

- Polyethylene tarpaulin (optional)

- Rotary saw or disc saw (if reinforced steel bar)

- Rotary drill hammer

- Goggles

- Sledge hammer, electric or pneumatic chisel machine