Author:

Roger Morrison

Date Of Creation:

22 September 2021

Update Date:

17 June 2024

Content

A sharp chainsaw not only saves you effort, but also reduces wear and tear on the device and makes it safer to use. In addition, dull saws do not cut straight. Here are some tips for sharpening your own saw.

To step

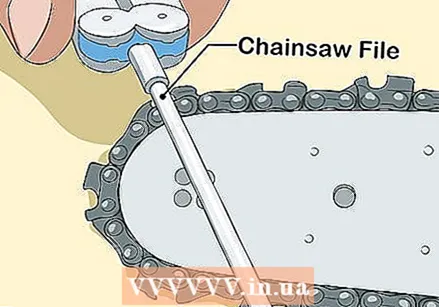

Determine the size (or measure) from the chain of your saw. You will need to purchase a rotary sharpening stone or chainsaw file that will match the teeth of the chain. Since there are different sizes of teeth, the sharpening stone or file you choose must be the correct diameter for your saw. Typical dimensions are 4.7 / 3.9 / 5.5 mm (3/16, 5/32, 7/32 inch) in diameter.

Determine the size (or measure) from the chain of your saw. You will need to purchase a rotary sharpening stone or chainsaw file that will match the teeth of the chain. Since there are different sizes of teeth, the sharpening stone or file you choose must be the correct diameter for your saw. Typical dimensions are 4.7 / 3.9 / 5.5 mm (3/16, 5/32, 7/32 inch) in diameter.  Clean the chain thoroughly. You can use turpentine or a commercial degreaser to remove oil, dirt, and grime from the chain. Do not let the cleaner get into the motor or in excessive amounts on other parts, some products can damage the plastic housing and other parts.

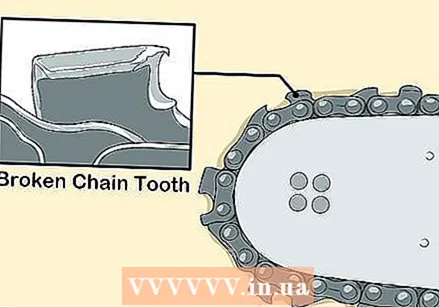

Clean the chain thoroughly. You can use turpentine or a commercial degreaser to remove oil, dirt, and grime from the chain. Do not let the cleaner get into the motor or in excessive amounts on other parts, some products can damage the plastic housing and other parts.  Inspect the chain for damaged and badly worn links and teeth. Individual teeth can break or bend, making them dangerous to use. As a guide, you can use the top plate (the flat surface on top of the saw teeth) to be at least 6.3 mm long. If it is shorter, there is a risk that it will break during cutting. Damaged, weakened and very worn chains must be discarded.

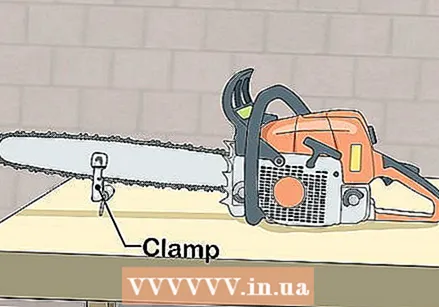

Inspect the chain for damaged and badly worn links and teeth. Individual teeth can break or bend, making them dangerous to use. As a guide, you can use the top plate (the flat surface on top of the saw teeth) to be at least 6.3 mm long. If it is shorter, there is a risk that it will break during cutting. Damaged, weakened and very worn chains must be discarded.  Place your saw on a sturdy surface, or clamp it in a vise. The saw must be stable and the blade well supported to sharpen safely and accurately. Clamping the saw in a vise, with the jaws clamping the bar and allowing the chain to rotate freely, is your best option.

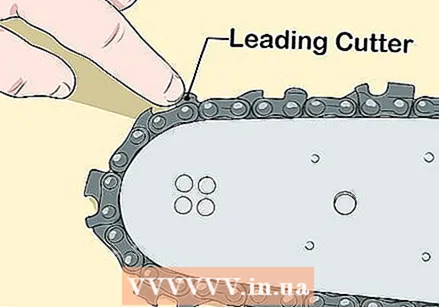

Place your saw on a sturdy surface, or clamp it in a vise. The saw must be stable and the blade well supported to sharpen safely and accurately. Clamping the saw in a vise, with the jaws clamping the bar and allowing the chain to rotate freely, is your best option.  Find the master link to get you started. This is the shortest sawtooth on the chain. When all the teeth appear to be about the same length, you can start where you want. Most importantly, sharpen each tooth so that the flat edge on each tooth is almost exactly the same length. This ensures that each tooth cuts away the same amount of wood while cutting. It can also help to mark the first tooth you grind with a speck of paint or marker so you don't forget where you started.

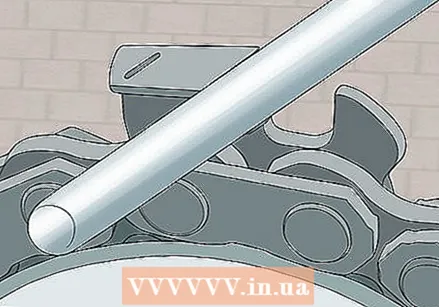

Find the master link to get you started. This is the shortest sawtooth on the chain. When all the teeth appear to be about the same length, you can start where you want. Most importantly, sharpen each tooth so that the flat edge on each tooth is almost exactly the same length. This ensures that each tooth cuts away the same amount of wood while cutting. It can also help to mark the first tooth you grind with a speck of paint or marker so you don't forget where you started.  Place the file in the slot on the front of the saw tooth. This is the angled one tooth at the front of the flat surface of the chain. The bend of the file must exactly match the bend of the front of the cutting tip, in addition, the top 20% of the file diameter must be above the tip of the tooth.

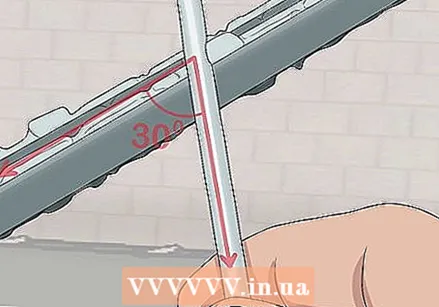

Place the file in the slot on the front of the saw tooth. This is the angled one tooth at the front of the flat surface of the chain. The bend of the file must exactly match the bend of the front of the cutting tip, in addition, the top 20% of the file diameter must be above the tip of the tooth.  Hold the file at the same angle as the sawtooth was originally. The angle can be 25 or 30 degrees (check the saw's specifications). Some specialty chains may have a flatter angle. In any case, it is essential to keep the original angle of the saw teeth. Have some teeth markings for visual support.

Hold the file at the same angle as the sawtooth was originally. The angle can be 25 or 30 degrees (check the saw's specifications). Some specialty chains may have a flatter angle. In any case, it is essential to keep the original angle of the saw teeth. Have some teeth markings for visual support.  Slide the file over the front of the saw tooth, in a moderate circular motion, to remove metal chips. There is disagreement about the best direction for this movement, but usually it is good to work from the short side of the corner towards the point that is too long. You then get a smoother cutting surface (an important detail!).

Slide the file over the front of the saw tooth, in a moderate circular motion, to remove metal chips. There is disagreement about the best direction for this movement, but usually it is good to work from the short side of the corner towards the point that is too long. You then get a smoother cutting surface (an important detail!).  Work each tooth identically from the starting point. Move the chain by hand while machining each tooth so that the tooth you are working on is on top of the bar.

Work each tooth identically from the starting point. Move the chain by hand while machining each tooth so that the tooth you are working on is on top of the bar.  When you have sharpened all the teeth, turn the chain over and continue with the unsharpened sides in the other direction. Consider the length of each flat top of the teeth. Some manufacturers suggest measuring the size with calipers to obtain a proportional cutting performance. However, if you have an eye for it, you can probably get a good result even without measurement.

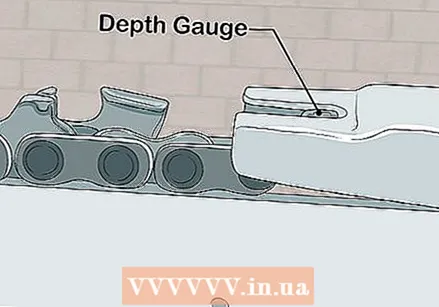

When you have sharpened all the teeth, turn the chain over and continue with the unsharpened sides in the other direction. Consider the length of each flat top of the teeth. Some manufacturers suggest measuring the size with calipers to obtain a proportional cutting performance. However, if you have an eye for it, you can probably get a good result even without measurement.  Check the space between the blades (depth gauge), the curved hook-shaped links between the teeth. They should end about 2.5mm below the sawtooth. These links control the amount of wood removed each round of sawing. A special tool is available from chainsaw dealers or DIY stores that can be placed on top of the blade. If the size is too high and needs to be filed, this tool will protect adjacent teeth while you are filing.

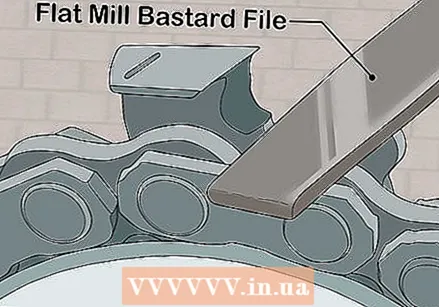

Check the space between the blades (depth gauge), the curved hook-shaped links between the teeth. They should end about 2.5mm below the sawtooth. These links control the amount of wood removed each round of sawing. A special tool is available from chainsaw dealers or DIY stores that can be placed on top of the blade. If the size is too high and needs to be filed, this tool will protect adjacent teeth while you are filing.  File any depth gap affecting a saw tooth (i.e., one that is too high), use a flat mill saw file (unlikely to be needed unless you are working with a broken chain).

File any depth gap affecting a saw tooth (i.e., one that is too high), use a flat mill saw file (unlikely to be needed unless you are working with a broken chain). Lubricate your chain (saturate / dip in oil) and check the tension, you should then be ready for another round of sawing.

Lubricate your chain (saturate / dip in oil) and check the tension, you should then be ready for another round of sawing.

Tips

- Periodically check for wear on the links, blade grooves and gear. Chains can break and cause serious injury and death when used with worn or damaged parts.

- Buy the right size file for your saw.

- Use the chainsaw sharpening instructions to maintain the correct sharpening angle while sharpening.

- It is recommended that a chain be professionally sharpened after it has been manually sharpened 5 times to correct any variations in the teeth.

Warnings

- You may not need to Brand chains to use. General store brands are often made by the same companies, with the same design specifications. As you might expect, manufacturers do recommend using their own oil, chains and rods. If you are using a chain that has been correctly adjusted for height, depth and profile, you should not have any problems.

- If a chain is adjusted while it is hot, you may need to rework it after it has cooled.

- wear gloves and goggles during the grinding process. You work with very sharp edges, you can easily cut yourself without gloves. When sharpening by hand, safety glasses are not necessary.

- Manufacturers recommend checking and adjusting chains often, especially when using a new chain (the tightening period). Oregon Chain recommends checking regularly during the first half hour of use.

- Do not force the file. It can break if too much force is applied. A file of the correct size should glide smoothly over the teeth.

- Not all chain bars are generic in how they are attached or adjusted, so make sure these features match your saw before purchasing a specific bar.

- For best results, adjust chains when they are cool, as all chains tend to loosen (expand) in the warmth of operation, even after the tightening period.

- Never run the saw while sharpening. Only move the chain by hand during the sharpening process. For safety, it is good to disconnect the spark plug before working on the chain.

- New or sharpened chains should always be used with care. It is recommended to use a new or sharpened chain fully in the recommended oil.

Necessities

- Chain saw file (correct size for your chain).

- Flat grinder saw file.

- File guide or gauge.

- Safety equipment

- Nut to adjust the saw bar

- Cleaning agent and rags